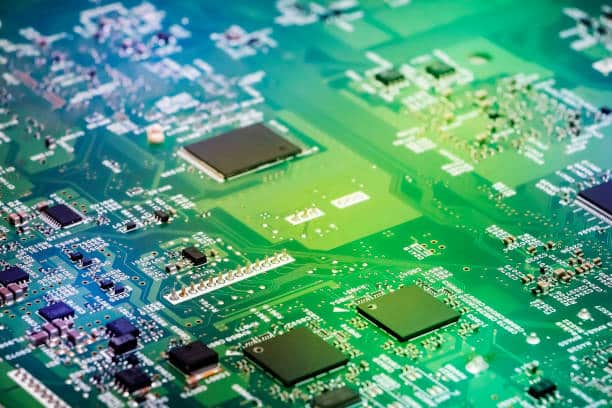

Do you know why PCBs (printed circuit board) often comes with green color? If it’s a healthy habit that you should add to your holiday shopping list is checking the inside of most of electronic devices for the characteristic green shade of the PCBs. This is not a random color. There are evident historical, practical, and cultural factors, which play an great role in choosing this color.

Historical Origins

It was proved to be effective when the green solder mask (it was used for the first automatic board maker in 1965 to produce printed circuit boards) was made to be the material that gives PCBs the color green at the early days of electronics production process. In the mid-twentieth century, corporations as Olin Corporation and DuPont started the production of protective glass epoxy-based materials, allowing to apply them not just on the copper traces, but to the whole green circuit board to protect them from oxidation and other types of damage. Green was usually chosen as color that has been adopted for PCBs.

Why are circuit boards green?

The boards quite often have that green look because copper traces remain underneath the solder mask. This color helps the parts to be visible and makes the assemblies contrast well with the other components, and also while on the road in the dark the green reflection is helpful in spotting any potential defects or problems during the manufacturing and repair process or to other next board. Its because of the solder mask, which this one will protects the copper circuit boards to the fibber glass core just to prevent the short circuits and soldering errors, etc. Which is also the color of the solder mask it will give the printed circuit boards an appearance for have a better understanding.

Do Printed Circuit Boards have to be green?

No, Though PCBs (printed circuit boards) do not have to be green colour, it is possible to produce them using eco-friendly methods. Although green creates is by far the most wide-spread color caused by a historical reason and the fact that it is best for addition of the color contrast and soldering it is also the one most often used and then remove the excess solder mask oil and wash the silkscreen before applying the new color.. However at present those regulator boards are available in the colors such as red, blue, black and others. Picking up color is all about the aesthetics or technical specifications depending on the manufacturer’s taste or certain applications.

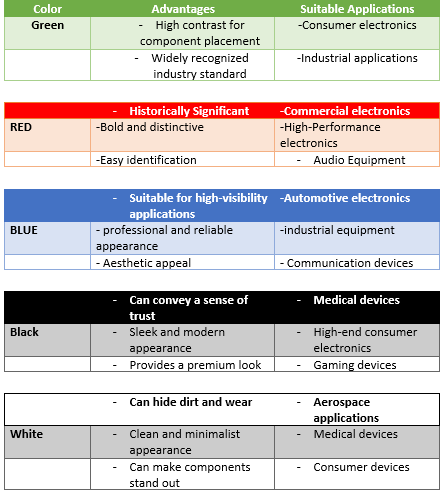

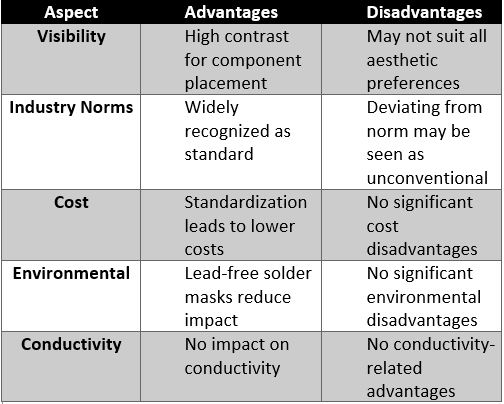

What are other available pcb color?

Besides the common green, also colored PCBs are produced. Some of the most common colors include:

Red

It is worth emphasizing that the slogan “Life is a bit more fun and bold” is one distinguishing feature from the other, and is commonly used to add a splash of color to consumer electronics and high-performance applications.

Blue pcbs

Expresses professionalism and reliability mostly used in industrial and commercial electronics applications.

Black

Provides with a premium and futuristic appearance, it is widely used in luxury market areas and gaming gadgets.

White

Gives a sleek look and feel akin to classy products such as consumer electronics and medical devices.

Yellow

Has a dynamic and aesthetic appearance, designed for applications that require customization or specialized uses.

Purple

Uniting a unique and fashionable presence, mainly employed in custom or specialty areas.

Top Reasons Why Most PCBs are Green in Color?

The top reasons why most Printed Circuit Boards (PCBs) are green in color are:

- Green may be a suitable element to aid in reducing visual fatigue and inspections.

In the first place, owing to technological limitations, quality control, workers need to go from board to board and to do this with their eyes and naked hands which makes the process slow. Does the thought of squinting at very small circuits in green light all days seem perturbing to you? It is not new to you to know that the neurologists and psychologists who have tested the effect of green light on the body come the same conclusion that it reduces fatigue. Likewise, they have confirmed that the two kinds of sensors in human eyes, or cones, are excitable to green light the most. This is also showed in a more striking selection for the tracks, pads, silkscreen and empty spaces. Observing boards from the outside of put it in a word, one can simply identify defects in outer layers or ne can easily identify defects in the outer layers. . Try red-green boards to different colors, that is, blue, yellow or black and white in turn. In large print, high contrast errors are easier to catch. - Contrast and Visibility

A green sign is used for high contrast against the white silkscreen applied when the components are labeled on the board. This simplifies the process for pcb manufacturer as they can easily allocate and subsequently locate individual components during assembly process. Discuss the ethical concerns surrounding the use of animal testing in scientific research by exploring the welfare of the animals involved, alternative methods, and the impact on potential drug development. - Solder Mask Composition:

Utilizing the green soldermask made of base material which is a good barrier to the oxidization and environment deterioration to copper solder layer on the supplied circuit boards is recommended to solder mask colors. - Cultural Norms:

The green color has evolved into a prominent brand identity in the electronics industry that nowadays has a great recognition as the standard color for PCBs. Differences from this particular color may suggest non-conventions or inappropriate matter. - Through PCB Disposal, however, the military is responsible for a large green part of this life cycle of manufacturing.

An opinionated perspective states that the green color and uniform are chosen because they were made military standard. American military blueprints included a variety of PCB colors or circuit board colors apparently; however green was the “optimum” one, provided the soldiers operated in hostile conditions.It was their tests that resulted in the military specifying green print circuit board, instead of other types. The military sold their pcbs to niche pcb manufacturers who, in turn, supplied green circuit boards to medical, industrial, and consumer electronics industries and electrical performance. The electronic components for personal computers didn’t have to be colorful because 99 % of time, there were no human eyes looking at a PCB aside from manufacturers. - Green Can Keep Workers in High Spirits, as it is Relieving and Visually Appealing

As per researches green is eye’s easiest color to see, green is the easiest to be scene for. This is red-blue throng. Green is central to the spectrum, being near the middle at 555 nanometers. Thus, the color green results from the interaction of the three basic colors most easily identified by the human eye and relieve visual fatigue. Thus, in regard to something small and complicated like a PCB, obviously the option to be green is always the best decision to make. As a PCB is glanced by the human eyes and eye strain, their health is confronted with a high level of strain. Because of the green color workers can easily recognize defects without being eye tired as many employees at small PCBs inspection stations. They are enabled by the device to inspect the details of the entire assembly and will be able to undertake a comprehensive check of the printed circuit board (PCB). Other color fatigue become often but the problem is fading more quickly. Combining green will give a considerable brightness difference. The bright green of the solder mask and the darker circuit traces, pads, and lettering become noticeable now. - The color of the PCBs may be critical; however, making a Choice on the Green color as the Primary color for them will be cheaper.

There is no doubt that every enterprise involved in pcb manufacturing is interested in costs, thus the appearance of green PCB substrates came about. In other words, the price of using green color is comparatively lower than other colors that would be retrofitted. - Environmental Considerations:

The green color is connected to Earth, its natural reserves, ecology, and kind to the nature environment. In the case of PCBs, the green color might be taken to mean the commitment of an industry to bringing down its environmental impact, since most of the current processes that have PCBs call for a little or no waste and to apply environmentally friendly materials.

Material Components Of Circuit Boards green solder masks

In terms of the material components of developing Printed Circuit Boards green, the same components are used for a a colored PCB as well. The green color of the PCB stands for the green solder mask – the thermosetting polymer coats applied as a protective layer over the copper traces and ensure the insulation. The primary components of a green PCB include:

- Substrate: Generally FR-4 laminate composite is employed for its shape maintaining and insulating functions, therefore copper conductors are sandwiched between them.

- Copper Foil: Important part of the PCB production stages is installation of copper lost into the substrate in order to make the traces for the components connecting.

- Solder Mask: The layer with a green color filler of the polymer is formed over the copper traces to protect them from oxidation and undesirable contact.

- Silkscreen: A white ink film over the solder mask becomes the final protection to indicate the components as well as the assembly instructions.

- Surface Finish: A covering added on the copper traces which is exposed to provide a better solderability and evade corrosion.

- Plated Through-Holes and Vias: Tin-plated holes for mechanical connections to different layers of the PCB board as well for performing traces routing.

- Component Pads: The areas of copper that are not covered by a conductive area or a solder area is where the PCB should be added to.

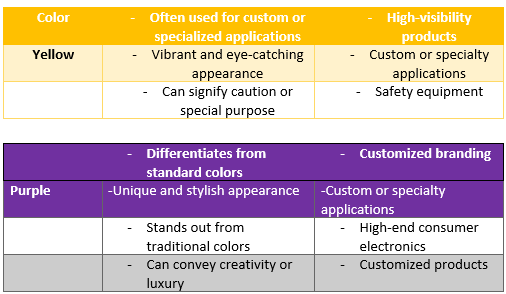

Different colored PCBs, their advantages and suitable applications

The conductivity level and cost per unit of each material costs

A kindly remembered that the conductivity levels specified is depending on those of the material’s mentioned and the matter applied and have default choice. Furthermore, among the factors that influence price are the source, the order quantity and the market cases.

Chemical Processes In Circuit Boards green solder masks

Manufacturing of green solder mask by PCB requires several chemical properties actions. Here’s an overview of the key steps involved:

- Preparation of Solder Mask: Different materials which are required to prepare the material like solder mask are mixed like epoxy resin, hardener, and colored pigments. The cadmium is the substance that makes the mask color green.

- Application: Solder mask, an entity which protects the surface of the circuit board from environmental hazards, is then placed on the board by utilizing methods like screen or silkscreen printing and spray coating. The solder mask is applied in a fine and smooth fashion all across the area of the board.

- Curing: When oven-cured, the heat resistant mask finishes its process or solder resist. Through the cure process, epoxy resin hardens to form a solid, scratch-free coating on the copper lines underneath.

- Exposure: First, the solder mask should be subjected to UV light exposure for cure via a mask or a stencil or exposure rate. Through the UV light, the solder mask would cure in exposed areas as well as the areas not covered by the mask would remain uncured.

- Development: The other boards is consequently dipped in a developer solution which removes all the uncured solder mask from the remaining board , leaving only the and the stubborn cured mask to remain. With this technique, the product designer can determine the places where the chips will be soldered on the board.

- Post-Cure: Lastly the board surface will sometimes go through a process of post-curing which is done to ensure the solder mask is fully cured and to enhance the bond between the solder mask and the PCB surface.

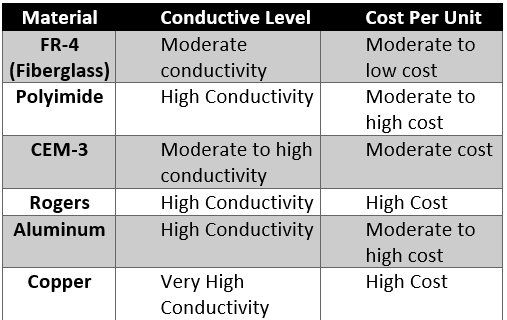

Environmental And Economic Factors For Green PCBs

Environmental aspects of the pcbs green are the vendibility of lead-free solder to attenuate the countervailing effect and recyclability of materials. Not only creating economically green PCBs are cost-effective through the standardization and usage of the approach, but also save manufacturers costs.

Advantages and disadvantages of green color for circuit boards green

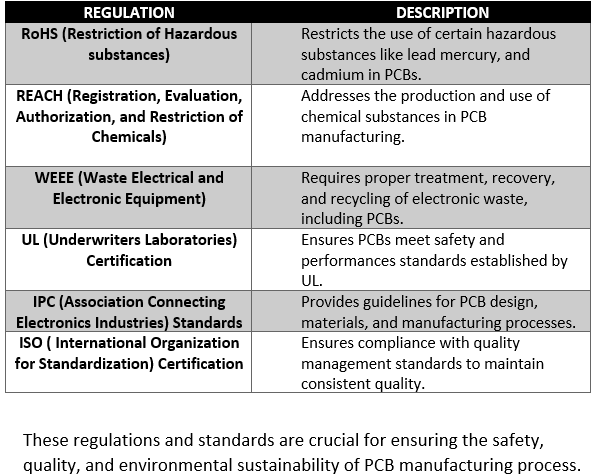

Regulations on Printed Circuit Board manufacturing process

FAQS

That’s correct! Printed circuit boards PCBs color does not affect how they are manufactured it is only the surrounding temperature that makes difference on the PCB melting and bending point. Such color is a result of solder paste, liquid melted at low temperature, which is applied to coat the copper tracks and protect from oxidation. The solder mask follows the PCB circuit board manufacturing but the color of mask coat that envelopes it does not affect the manufacturing process. Hence, through such manufacturing, PCBs can have different colors without having to interfere with the actual process of fabrication.

In the course of historical evolution, blue became the leading color for printed circuit boards because of the existing reasons, practical matters, and industry standards. But there are also some others that they rely on depending on the usage and design causes.

Of course, different colors are available from colored corner printed circuit boards, red, blue, black and others. The way color is chosen in this case is often down to the manufacturer’s views or there could be some specific needs for the application at that particular time.

No, the colour of a circuit board doesn’t affect it with higher capabilities or characteristics. The color is there only to serve as a visual touchpoint and does not alter the board’s electric functions or utilities.

Green in color create a high contrast showing an excellent picture when white silkscreen used for labeling components is on board side, hence, the placement of components on the board is easy for manufacturers.

Majority of the circuit boards are usually made up of green solder layers due to the position of the solder masking done over the copper layers for protection from corrosion and separation of neighbor copper traces.