This comprehensive guide provides an in-depth understanding of the different layers of a PCB (printed circuit board) such as the copper layers, signal layers, multiple layers, mechanical layers, outer layers and inner layers and their functions. Explore the importance of each layer and how they contribute to the overall functionality of the PCB.

WHAT IS A PCB LAYER?

In this article the pcb layers explained and of course must define first what is a PCB layer, which can be referred to as a printed circuit board layer is sheet or level that forms an integral part of the entire PCS and contains various components such as conductive paths whereby electrical connections take place. To provide a reliable platform to support and retain various electronic components, printed circuit boards (PCBs) are used on many devices. On a printed circuit board (PCB), every layer is associated with particular functions, including signal transmission, power or ground planes and specifying certain lines.

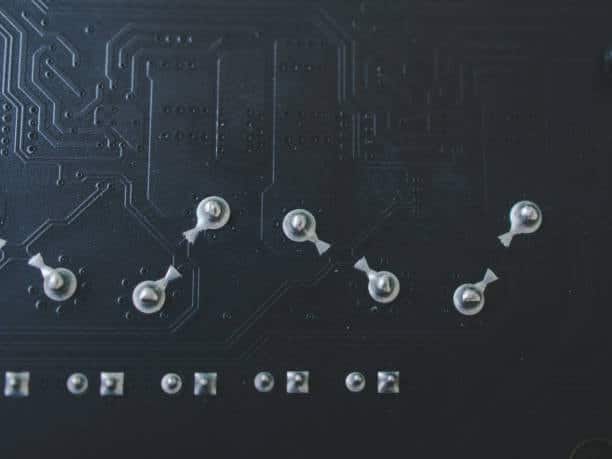

These layers are typically made of a laminate material like fiberglass or epoxy resin, with copper foil on both sides. After it, the copper foil is etched off in order to form proper circuitry. Each layer such as single layer pcbs, multi layer pcbs, double layer pcbs of the printed circuit board forms part of the overall function and complexity that define it as a finished product. The via function of these printed circuit board layers makes it possible to connect them horizontally and facilitate electrical impulses on the one hand. In general, printed circuit board layers play a vital role in the structural stability and functionality of electronic devices. It is their role to ensure that proper connections are made and the right signal routing.

What Are the Layers of Printed Circuit Boards?

Printed circuit boards (PCBs) have many layers, and all these levels contribute to the smooth functioning of electrical devices. A printed circuit board (PCB) comprises of four layers that are substrate layer, copper layer, solder mask and silkscreen layers, ground layers and more layers. Composed of a non-conductive substance such as epoxy resin or fiberglass, the substrate layer offers mechanical support which you can see solder paste layer . The copper layer of the printed circuit board is used for electric conductivity and holds the copper tracts that connect all other components on this podium.

Using the solder masks layer as a protective coating applied over the copper pattern helps in avoiding soldering bridging or solder flow and short circuits to the solder mask layers. In summary, the silkscreen layer consists of markings and component labels that help in assembly of components on printed circuit board (PCB) as well identification. As every layer adds to the performance and resilience of a printed circuit board (PCB), it is an integral part in modern electronic devices which is also you can see the solder paste layers or more layers.

Types of pcb layers

The number and type of layers found in pcb layers may significantly differ a fact that greatly affects the level design complexity, as well as board functionality. The most common types of printed circuit board layers include single-sided, double-sidded and multilayer pcbs or multilayer board. Single-sided printed circuit boards (PCBs) have a single side of the board, which does not possess more than one layer conductive material – usually copper and then you see how many layers for one layer. These are simple and cost-effective but also come with a limited set of functionalities that often support basic applications.

The application of PCBs with conductive layers on both the sides means that more intricate circuitry and components can be placed. Besides being utilized in the manufacturing of small electronic gadgets, they help to ensure better signal integrity and thermal optimization. Multi-layer printed circuit boards (MLPCBs) are separated by insulating materials such as substrates into three or more conductive layers and also there is single sided pcb.

These advanced PCBs are used by complicated electronic gadgets that provide numerous benefits such as better efficiency, reduced size, lower noise, and enhanced sign fidelity. Since they are expensive and require high production standards, they should be used for sophisticated applications like cellphones computers aerospace equipment some are having eight layer pcbs, two layers, four signal layers and then you can additional layers.

Finding the number of layers

One of the steps that are necessary in designing and manufacturing a PCB board is determining the number of layers. A greater number of layers directly affects the functionality, complexity and cost associated with a PCB board. For the number of layers, various aspects must be taken into account such as single layer pcb, upper layer, inner layer, mechanical layer, double layer, or multi layer boards. Initially, the number of layers necessary will be determined by the intricacy of circuitry itself.

Secondly, size and dimensions of the board contribute to layer count. In the minimal space, there may need to be extra layers that allows for all required traces. Finally, cost forms an important consideration because as the number of layers grows higher so does its manufacturing cost. Thus the problem of finding the optimal number layers is about comparing complexity, size and cost limitations either eight layer pcb, single layer pcb.

PCB Layers layout rules

The PCB layer layout rules are the considerations and elements that have to be considered while designing the stack-up arrangement of layers in a given printed circuit board design. Some common PCB layer layout rules include:

1. Signal and plane layers

The standard PCB stack-up includes alternating signal and plane layers. The signal layers consist of the circuits’ electrical traces, whereas plane layers serve as a low-impedance reference. The amount of signal and plane layers increases or reduces depending on the complexity in a circuit as well as design requirements.

2. Power and ground planes

However, placement of power and ground planes together offers a direct path for current flow with minimum noise featuring the right impedance. It would be best if the signal layers have their respective power and ground planes placed side by side.

3. Layer order

Accordingly, the layer orders should be arranged in such a way as to reduce crosstalks and noise coupling between adjacent signal layers. It is a common practice to put high-speed, noise sensitive signals between power or ground planes.

4. Layer symmetry

The symmetric distribution of the level layers improves signal integrity while minimizing electromagnetic interference (EMI). Symmetry is achieved by matching identical signal layers on the opposite sides of a PCB stack up.

5. Controlled impedance

High-speed signal integrity should be maintained with controlled impedance. It is achieved by the way layers are organized and constant trace width, spacing, dielectric thickness. PCB fabrication and assembly vendors should be followed by the guidelines.

6. Signal routing layer

Signal traces must be routed on the correct signal layers to minimize interference and crosstalk. Internal layers are recommended for better shielding and controlled-impedance placement of high-speed, differential pairs as well as sensitive signal traces.

7. Layer stack-up documentation

In PCB fabrication, assembly and testing, proper documentation of the complete layers stack-up is a requirement. A complete description of materials, thicknesses, trace routing and impedance profile should be given.

It is also essential to mention that particular layer layout rules may change depending on the design specifications, complexity, and desired performance level of PCB. By adhering to industry standards and seeking advice from seasoned PCB designers, one is able to put the best layer layout practices in place for a type of design.

types of mask layers

The various types of mask layers in a PCB board are used for different functions. Some of the commonly used mask layers include:

1. Solder Mask (LPI or Liquid Photoimageable Solder Mask)

It is a covering layer of the copper traces and keeps solder from flowing to undesired locations during soldering. It is usually green in colour, except for other colours such as red or blue ones.

2. Silkscreen or Overlay Mask Layer:

This layer includes component designators, logos, symbols or any other printing geometrical shapes on the PCB surface. It identifies the components and helps to direct during installation as well as servicing.

3. Peelable Mask Layer:

This temporary mask layer is used for processes such as wave soldering or selective solder When soldering is completed, it can be easily removed.

4. Conductive Ink Layer:

For some applications, conductive ink is printed in the PCB to make electrical connections or traces This ink layer incorporates a conductive path between the components or tracks.

5. Coverlay Mask Layer:

In flexible printed circuit boards or flex-rigid PCBs, the coverlay mask layer is employed. It is a covering layer of the flexible circuits that insulates against moisture, dust etc.

6. Carbon Mask Layer:

In other instances, a carbon coating is applied to the surface of a PCB in order to provide shielding. This layer provides shielding from EMI through absorption or reflection of undesirable radio frequencies.

7. Anti-Static Mask Layer:

Where ESD protection is necessary in particular applications, an anti-static mask layer is deposited on the PCB’s. It minimizes the static charge and protects delicate parts from damages.

What is worth mentioning here is that the mask layers in PCB design can vary both by quantity and quality.

How will my printed circuit board be used?

Printed circuit boards include PCBs that are used in many electronic devices and systems. They are responsible for enabling the work of complex circuits by creating a ground for electronic components to connect and communicate with one another. Items such as computers, mobile phones, television sets and kitchen appliances are the daily sources of PCBs.

These boards enable quick transmission of power signals between components, eliminating a lot wiring while improving the device’s reliability. PCBs, can be customized and upgraded with ease as they provide modularity. The advancements in technology have resulted to the diminutive nature of PCBs which is compact such that they can be portable, even flexible and hence wearable devices find use. In general, PCB technology is an essential tool in making the modern electronic devices work efficiently and reliably.

What operation frequency is needed?

The frequency needed during operation in a PCB board may change based on the application of use. It runs from low frequencies in the kHz realm for basic uses to high frequencies within GHz limits associated with advanced technologies such as wireless communications or fast digital signals. The operation frequency that is expected to be required for implementation and application purposes, however, depends a number of factors relating to signals being transmitted or processed; system requirements such as desired bandwidth among others.

What is my budget for the project?

To figure out what would be a reasonable budget for your personal PCB circuit board project, one needs to take into consideration the design’s intricacy as well as number of layers, scale measurement and how many will you need them although any additional features or specifications should not go unnoticed either. Other cost factors encompass fabrication, assembling, testing and transport.

Normally, a PCB board project cost can vary between hundreds and thousands of dollars. Small, plain boards that have less complexity and fewer layers are usually inexpensive; large complicated ones with a greater number of sheets can be expensive.

It is advisable to seek the help of PCB manufacturers, assembly houses or design service providers who will give quotations according to your specific project needs. They can evaluate the requirements, give quotations and help you come up with a reasonable budget for your project.

How quickly do I need the PCBs?

It all depends on factors such as the design, multilayer-ness and PCB manufacturer’s fabrication facilities. In general, the delivery speed of getting PCBs can vary from several days to a couple of weeks.

In standard specifications and without special manufacturing requirements, a lot of manufacturers provide quick turnaround times from 2 to 7 days. For small medium-size orders But it is possible to have faster production alternatives, such as expedited or express services that already cuts the lead time significantly.

It is advisable to inform the PCB manufacturer of your particular time needs initially as they can make an estimate calculation of delivery date according to what job workloads are ongoing and their manufacturing capacity. Still, note that quicker turnarounds may involve more charges.

What density and signal layers are needed?

The PCB board needs to determine the required density and signal layers based on specific requirements of circuit design. In general, PCBs can be configured in a single-layered to multi-layer form.

PCB density refers to the number of components, traces and routing that could fit into a specific area. It determines how elaborate and effective the board can be. Complex circuit designs that include a large number of components and traces closely spaced are employed on PCBs constituting high density.

Signal layers are defined as the number of signal or routing layers in a PCB. Every signal layer comprises traces and vias that enable the transmission of signals to/from various components & elements within a circuit. The additional signal layers facilitate improved routing and reduce the likelihood of interference or crosstalk.

PCB density and signal layer choice are determined by factors including circuit complexity, number of components required, desired electrical performance requirements , restrictions on size among others. It is advisable to discuss with a PCB designer or an engineer, in order to find the best layer arrangement appropriate for any given design of the layout matrix.

Six-Layer PCBs

A Six-Layer PCB (Printed Circuit Board) is a printed circuit board that has six conducting layers joined by insulating layers. These layers are comprised of copper traces or conductive materials and serve as interconnections between electronic components and circuits on the board. The number of layers in a PC may reflect the level of complexity and functionality of ring design. Six-layer, it offers more advanced designs and multiple links that provide trace flexible routing path while eliminating the problem of signal interference to the dielectric and conductive materials. This is driven by the fact that it fits well into more advanced and complicated electronic devices such as computers, communication gear, medical equipment machines used in industry.

Complex Multilayer PCBs

So, multilayer PCBs are printed circuit boards (PCB) with multiple copper traces and insulating layers. These PCBs are used in the electronic devices that include a large number of components and complex circuitry.

A multi-layer PCB is made up of several layers, each being a conductive material such as copper and having in between them insulating layers like fiberglass reinforced epoxy resin in manufacturing process using conductive copper to the dielectric material. In these PCBs, the number of layers ranging from four to several dozen depends on how complex are as well as the needs that need special attention for any device either in the internal layers, mechanical layers or in the inner layers.

The conductive layers are further linked via vias, which were small holes drilled through the insulating materials and coated with copper layers to the dielectric material. Such vias provide electrical connections between different layers of the PCB, allowing for complicated circuitry necessary in nuclear detection systems in modern electronic instruments were you can see the copper layers you can see the internal layers on it either in the ground and power planes either in the single layer pcbs, mechanical layer or in the routing layer.

The extra layers present in the complex multilayer PCBs have several advantages. They facilitate increased packing density for electronic components and integration of more complex yet advanced circuits. The doubled layers also provide better EMI reduction and improved signal integrity due to superior grounding and shielding with different electronic components to component pin either in thermal conductivity.

Layer Distributions

Layers in a PCB (Printed Circuit Board), therefore, refers to the construction of various conductive and non-conductive layers that give rise to its structure. The typical layer distribution in a PCB is as follows:

1. Top Layer (Signal Layer):

This is the top layer of PCB on which most of electronic components are installed and wired by copper tracks or traces.

2. Inner Signal Layers:

These are extra sheets between the top and bottom layers that provide routing of signals for interconnection components on the board to thw top and bottom layers. In addition, the number of inner signal layers may differ due to design complexity which you can also see the routing layer.

3. Power Planes:

Such layers are reserved for transport of power and ground signals. They supply a constant voltage and ground reference for the other components on board that gives them stability by reducing noise interference.

4. Ground Plane:

This is a reference layer for the ground connection of the components. It protects delicate circuits from outside electromagnetic noise, acting as a low impedance return current path.

5. Bottom Layer (Signal Layer):

Like the top layer, this is used for mounting components and routing traces on the other side of it.

6. Silkscreen Layer:

This is an insulating layer that comprises text, symbols component outlines as well other markings helpful in positioning and identification of the components.

7. Solder Mask Layer:

It is this layer that covers the copper layers-traces and pads from oxidation, including preventing solder bridges during soldering. It is typically colored and non-conductive.

The choice of layers in a printed circuit board depends on the complexity of PCB layout, signal integrity requirements, power distribution preferences and other areas.