Work out the advantages and ways of no clean soldering through this complete “Ultimate Guide.” Discover how it’s innovating soldering experience, encompassing convenience and effectiveness with the integrity of quality results. Go through expert advice and approaches on exploiting no-clean soldering as a successful addition in your undertaking.

What is no-clean-soldering?

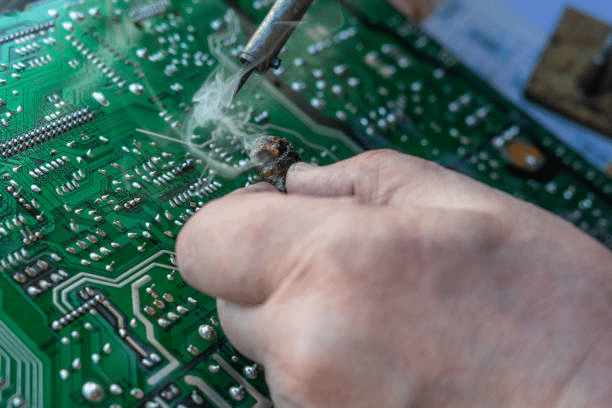

“No Clean Soldering” is a contemporary method of soldering that does not require in-depth clean-up after the soldering is done. Instead of leaving flux residues that are to be removed after soldering, it creates no clean paste and produces little to no debris. Therefore, it has the nickname “no cleaning soldering.” This not only saves time but also resources, while environmental effects from cleaning processes will be reduced.

What are the types of no-clean flux?

Different types of no-clean flux formulation are being offered in these days. Each type of formulation is designed for particular soldering purpose and working condition. Some common types include:

Rosin-Based Flux: Rosin-based fluxes are a product of natural rosin and they are broadly used in modular soldering. They promote reactant mixing activities and prevent debris dispersion and accumulation.

Water-Soluble Flux: Water-soluble fluxes contain activators and natural acids, which are then rinsed off by hot water, helping in the process of post-solder cleaning. Most of them find their applications in areas where sterility is highly emphasized, like mobile phone assembly.

Halide-Free Flux: Flux formulations based on halide-free technology are devoid of halogen components like chlorine and bromine. They are first-choice candidates for cases where halide-deficient environments are likely due to corrosion or reliability problems.

Low-Solids Flux: Low-solids fluxes, as an example, are low-activator and low-other-solid component solutions, which ultimately have little residue in buried metallic joints. They are largely incorporated into processes where visibility or conductivity of debris is an issue to address.

Activated Rosin Flux: Interacted rosin fluxes have additional cleaning and wetting properties activators for their purpose. They are well-suited to reflow temperatures in soldering in high or demanding conditions or for difficult surfaces that are tougher to wet.

Synthetic Flux: Synthetic resins and organic acids are organic substances, and all together, they form synthetic resin flux. They provide for good strength and wetting performance, which makes them useful not only for SMD parts but also for traditional through-hole soldering processes.

Isopropyl Alcohol: Such no-clean soldering flux-based soldering processes give manufacturers more freedom and options depending on the materials and the purpose of the component. Selecting the best no-clean flux type will be dependent on many variables, including the specific application purpose, campaign delivery, and the level of desired aspect cleanliness.

Does no clean soldering process use water-soluble flux?

The no-clean soldering process do not usually involve water-soluble flux. Solder with no flux cleaning uses fluxes, which will dissolve around 95 percent of residues in the solder, enabling post-solder cleaning process.

In no-clean soldering, the solder flux composition is built to be non-corrosive and non-conductive, meaning that any extraneous soldering left after soldering will be minimal, which cannot tamper with the connection’s usefulness and reliability. Thermal interface material in an electrical system makes good electrical contact between components and printed circuit board (PCB) traces more effectively, thus minimizing the risk of electrical failures.

Hot Water-soluble clean fluxes are effective for instances where compromising cleanliness is not an issue. However, they are not usually part of no clean soldering processes because they leave residues behind and their cleaning requirements are too high, which can lead to broken bonds since mild cleaning agents are absent.

What are the differences between no clean soldering, clean soldering and traditional soldering methods?

These are the differences between no cleaning soldering, clean soldering and traditional soldering methods:

No Clean Soldering

No Clean does not utilize cleaning flux or require post-soldering cleaning since the soldering iron heats the solder material to the point where it melts and assimilates with the metal surface it is in contact with. The low-density flux solder paste contains resin rosin, organic acids, activators, and various solvents. This approach is mostly used in instances where the debris is unviable or undue, for example, in electronics manufacturing. Low-debris soldering helps with convenient operation, quickens up production time, and makes reliable solder joints, all without sacrificing its function or performance.

Clean Soldering

Spotless soldering or clean soldering is achieved by using a soldering flux, and although the remaining flux is sparse, it can be cleaned off with solvents or water-based cleaners. The water-soluble ones are the most favorite among the environmentally friendly soldering. It is applied in cases where the residue should be eliminated according to certain requirements. For example, for the sake of a pleasant visual impression or to meet industrial standards. Clean soldering helps to get the solder links clean from impurities and impurities that have relevance, ensuring a sleeve pattern and long-lasting functionality.

Traditional Soldering Methods

The traditional soldering techniques usually require the use of soldering test pin alterants, which in turn leave more residue after the soldering process. This way, the residual can be corrosive or conducting, which forces it to be cleaned with the use of solvents or mechanical methods. The conventional soldering process involves more time and expense due to the requirements for cleaning steps, raising production costs in addition to its complications. While they are indeed a lasting application choice in some cases, cleaner ones are becoming more attractive substitutes. For example, there are no clean soldering solutions.

Generally, the different ways of soldering between these no-clean pastes and traditional soldering are noticeably set apart by residue left behind after soldering and the need for post-solder cleaning. No clean soldering does not leave behind any residue; clean soldering makes it easier to remove any resinous residue; and traditional soldering methods more often require extra cleaning as a result of the biggest amount of debris produced. Seeding techniques can be specific to certain applications, and options are given to choose from depending on industry standards and practices.

What are the advantages and disadvantages of using a non-clean soldering process?

How does this no-clean soldering method compare with the traditional soldering method? Here are some of its advantages and disadvantages:

Advantages

- Time and Cost Savings: high-reliability soldering not only greatly diminishes the need for post-solder cleaning but also the stage itself, the labor and materials for cleaning agents and equipment. So, you get not only the reduced time but also the cutting of the cost associated with the process.

- Improved Productivity: More so, this step cuts off the cleaning items from the manufacturing process and consequently, it reduces the set of steps that are involved, hence increasing the throughput and also the productiveness.

- Reduced Environmental Impact: Hence, the low-flux soldering limits the consumption of chemical cleaners and lessens the requirement of fresh drinking water, which results in a diminished carbon footprint produced by the manufacturing step.

- Reliability: Unlike traditional fluxes that leave their corrosive residues behind, the no-clean fluxes are formulated to have non-corrosive residue towards the base metals as well as the metals present during soldering. This is achieved by ensuring trustworthy solder connections while at the same time reducing the chances of electrical problems linked to impurities.

- Compatibility: Being debris-free soldering line working with a vast range of electronic parts and supplies makes it versatile and assembly line anywhere in the electronics industry and also boosts the overall cosmetic appearance of the final product

Disadvantages

- Debris and Cleaning Issues: Although they are rugged, soldering paste’s residue after soldering may be some, and it is possible that these solder paste residues may affect performance or aesthetic aspects for the most sensitive applications. In certain cases, water-soluble fluxes, which are highly compatible with water, may require cleaning and need to be treated separately. Use our automated writing assistants to save time and improve productivity.

- Compatibility Issues: Some passive parts or components cannot be connected to the typical no-clean flux, which in turn may force the use of an alternative flux. Such an action may lead to reliability problems or solder joints that are incompatible with other materials.

- Limited Effectiveness: If there are no real clean fluxes, their effectiveness could be limited in removing heavy oxides or contaminants from metal-furnished surfaces, like in the case of more aggressive cleaning methods. The possibility of weak solder wetting as well as joints with lower strength may stem from this consequence.

- Regulatory Compliance: This is because of the differences in requirements between different industries and applications. In this regard, one process may be regulated or customer-specified to be the recommended cleaner, and this could be subject to contradictions if no clean flux soldering is being used.

- Process Optimization: Due to the complexity of low-residue soldering with clock speed optimization, it may be necessary to optimize the processes in their entirety. Example: soldering temperature, time, and solder paste application, which will add complexity to the manufacturing process.

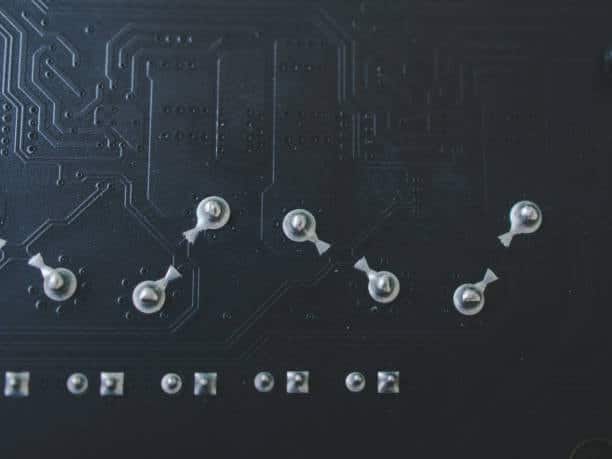

How does flux residue affect your PCBs?

Flux residue left on printed circuit boards (PCBs) can have several adverse effects on their performance and reliability.

- Electrical Insulation: Flux reside may serve as an insulating barrier between conductive lines or between components’ leads on the printed circuit board and may cause electrical connection problems. This can manifest in a wide range of ways, including intermittent connection downtime, error signals, and even circuit disruption.

- Corrosion: Not only some no-clean paste debris can remain as gabs, but gelling agents in them also digest metal traces and parts in the board. Oozing of the connection and producing the shorts (electrical shorts) and opens (open circuits) can also originate from solder ball corrosion.

- Hygroscopicity: The ensuing broth or gravy may not have excessive cleansing waste since no clean flux residue may be hygroscopic and hence absorb moisture from the atmosphere.

- Thermal Instability: Solder paste debris may have volatile thermal stability, depending on its type. As for flux residues, which may be broken down by exposure to heat,. These may generate corrosive byproducts or lead to unwanted changes in electrical properties.

- Interference with Testing and Inspection: Flux residues can hinder fine-tuned inspections through visuals and testing processes, which leads to difficult problems and defect identification during manufacturing or troubleshooting.

- Reliability Issues: Gradually, the slag or flux debris could be the source of degradation of solder joints and PCB units, which in turn leads to a decrease in trace amounts of the device’s reliability, service life, and also costs. Such problems can put pressure on electronics and systems and cause their early failure.

Conclusion

The use of no-clean up solder pastes is required in the route because of their better performance. The use of less clean solder pastes and paste formulations equipped to produce less residue may hence eliminate the necessity of post-soldering cleanliness, which will then also reduce production time while also releasing vital resources. Moreover, the lowered necessity to clean up the after seconds is a further factor favoring a lead-free and environmentally friendly manufacturing process, as it generally reduces the use of any potentially hazardous cleaning products.

No clean soldering guarantees that solder joints will not corrode over time by creating all kinds of residues that could endanger electrical connections and therefore pose a threat to the reliability of the printed circuit boards (PCBs). Furthermore, conformal coating acts in conjunction with clean flux soldering, which streamlines the solder process, enabling a higher throughput and thus optimizing production workflows, resulting in more effectiveness and less cost. To adhere to clean and dependable solder connections, it is important to get the flux formulation that will promote better adherence between the solder and the metal surface.