SMT Surface Mount Technology is an important way of PCB design. This article discusses the function of SMT in PCB layout and its advantages concerning space, work rate shakeup boosted by swift manufacturing. Understand this technology more deeply, incorporating it in electronic devices.

What is surface mount technology?

Surface Mount Technology is normally referred to as SMT and it’s an approach for the assembly of electronic components. It involves attachment of parts directly onto the surface area which is deemed equivalent to PCB assembly or printed circuit boards . On the other hand, SMT components are compared with usual through-hole technology where a component is put into holes onto printed circuit board (PCB). A distinction in SMT parts can be argued from those of conventional ones which have been produced using thinned and flat leads or contacts that were soldered directly on surface area of one’s board.

The possible advantage of using this technology properly can be to get a better smt component density, smaller and lighter electronic appliances as well as superior electrical performance of pcb manufacturing that has gained viability as the foremost technology in Electronics industry is smt assembly; with this, it was possible to develop devices used in electronics manufacturing which were more compact and energy efficient. These include smartphones, laptops and other consumer electronic items.

Where Did SMT Originate From?

Surface-mount technology, SMT was the first that came in 1960s as a way of making electronic gadget or those have external devices in surface mount device friendly to small and lighter versions. The main reason for its creation was the need of IBM to offer a more space-friendly and productive solution as compared with the traditional through-hole technology. The development of SMT was one of the factors in downsizing electronic components, as well as increased demands to improve such production processes like it Automation.

Surface-mount technology (SMT) has evolved to become the standard in electronics industry over past decades thanks to its several advantages. Some of these benefits are that one has a higher component density, increased reliability and there is also the ability to use automated assembly equipment; such as manufacturing yet at very low costs. As a result, the prevalence of surface-mount technology (SMT) may largely define current landscape in manufacturing electronic devices to those electronics manufacturing and to those electronics industry with their production process.

What is Surface Mount Assembly Process?

The Surface Mount installation Process is a method where electronic components are installed directly onto the surface of the printed circuit board (PCB) by using Surface Mount Technology. The following are the primary stages that are normally involved in the process:

Stencil Printing

Later on, a stencil is applied to the printed circuit board (PCB) or in the pcb assembly process for applying solder paste. A solder paste consists of flux and very tiny amounts of solder materials particles just like thin small outline package. The stencil is a metallic sheet that has perforations which represent the sections of the circuit board where components placement would be surface mounted devices.

Pick and Place

Automated machines known as pick-and-place machines accurately pick up surface mount components from reels or trays. The machines then align the components into the solder paste for solder paste printers spots on their printed circuit board (PCB). This category includes resistors, capacitors, integrated circuits and many other devices.

Reflow Soldering

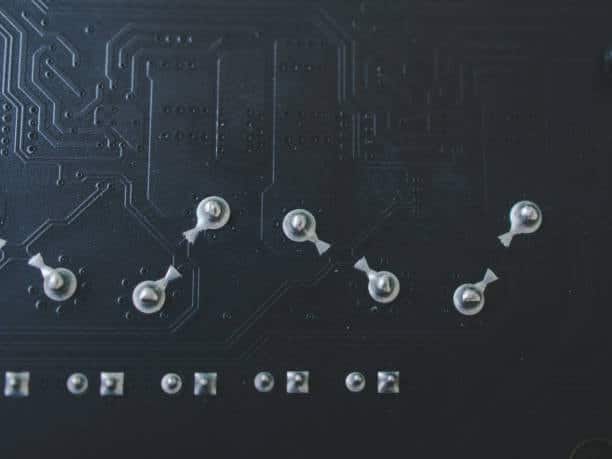

Then, the completed printed circuit board (PCB) is exposed to a reflow oven just like reflow soldering machine. In this oven, the entire board is heated for forming a good bonding between its various components and PCB since when using solder paste it melts. Solder is used to hold the components in place, when cooled it hardens and makes the board more solid.

Inspection

After reflow soldering the final PCB is subjected to checking so as it be assured that all components have been soldered and placed appropriately were automated optical inspection on it. It is possible to detect flaws through the use of automated optical inspection AOI, and other assessment techniques as well.

Secondary Assembly Processes

It may be necessary to perform additional operations like conformal coating, selective soldering processes or manual assembly for completion of the soldering process. This may depend on the design.

Testing and Quality Control

The final phase involves functional testing and quality control procedures in order to ensure that the built printed circuit board(PCB) meets all required requirements and standards. Various types of quality assurance tests like electrical testing, functionality testing etc. could fall under this category which you can test those electrical component mounted, electrical solder connections etc.

Packaging and Shipping

All quality tests having been successfully passed, the printed circuit boards PCBs are packed and prepared for shipping. Besides being part of larger electronic assemblies, the finished printed circuit boards (PCBs) can also be provided to end-users.

What are the Applications of SMT?

The Surface Mount Technology SMT encompasses a wide range of applications in various fields due to its efficacy, compact design ability and the capability to cope with higher component density. The following are some important uses of SMT:

- Consumer Electronics – SMT widely used in manufacturing of consumer electronics such as digital cameras, computers ,tablets and smartphones among other common electronic devices. Since these devices have high-performance requirements and are small in size, so surface mount technology is an ideal solution for their fabrication.

- Automotive Electronics – In the automobile industry, it is achieved through surface mechanics technology (SMT) in manufacturing electronic components and systems such as engine control units entertainment system navigation system sensors etc. SMT is a very important material for use in automotive applications as it possesses resistance to vibrations and temperature fluctuations.

- Telecommunications – The telecommunications equipment such as routers, modems and other networking devices rely on SMT effectively. SMT enables the smt manufacturing process of higher component density and also high-performance communication systems.

- Medical Devices – With the help of surface-mount technology (SMT) manufacturing technologies, a significant number and wide range of medical devices from diagnostics to implantables are produced. When referring to the medical industry, SMT deliveries downsizing and accuracy which are very important.

- Industrial Electronics – SMT serves as a benefit to many different industrial applications like controls systems, automation equipment and robotics etc. The use of printed circuit boards (SMT) components is appropriate in industrial applications because they have small size and high reliability.

- Aerospace and Defense – In the aerospace and military space, where different electronic parts are needed to meet high performance and reliability requirements; surface-mount technology (SMT) has an extremely important role. All those products; avionics, communication systems, radar systems and any other types of system that employ SMT.

- LED Lighting – The SMT manufacturing process is widely used in producing LED lighting devices. LED drivers, controllers, and other electrical components commonly used in lighting systems are assembled using surface-mount technology (SMT) under normal circumstances to achieve high manufacturing efficiency.

- Wearable Technology – Comparative to the bulky nature of plug-in components, SMT components are space efficient and convenient for wearable devices. Examples of the wearable devices include smartwatches, fitness trackers and health monitoring systems.

- Energy Systems – Surface-mount technology (SMT) has different applications, from the manufacturing of electronic components such as power inverters to energy storage devices and renewable energy systems. The relatively high component density and reliability of SMT is one characteristic that contributes to the effectiveness of these systems.

- IoT Devices – SMT is a very important technology for IoT devices as the amount of electrical components that are small and efficient in terms of power consumption is needed to support such networking.

Therefore, surface-mount technology (SMT) is a very versatile type of technology that can be used across numerous industries. It allows making electronic devices which are less in size, more efficient and reliable. The constant advancement we see in SMT contribute to invention of innovative ways of serving customers from different professions.

SMT devices

The electronic components that are meant to be attached onto the printed circuit boards (PCBs) via the Surface Mount Technology manufacturing process perhaps uses this term “Surface Mount Technology” or SMT, devices. Surface-mount technology (SMT) components, however in contrast to standard through hole parts don’t have long leads but either them are flat or there is no lead at all and they are soldered straight onto the printed circuit board of PCB. Some of the most frequent kinds of SMT devices are as follows:

- Resistors – Surface-mount technology (SMT) resistors are available in various sizes and shapes from the smaller chip resistor to bigger power resisters. They provide resistance to the flow of electric current.

- Capacitors – SMT capacitors have the ability to store, as well as release electrical energy. There are numerous varieties of capacitors available including ceramic capacitors, electrolytic capacitor and tantalum capacitors .

- Integrated Circuits (ICs) – SMT ICs may have some or all of the following components microprocessors, memory chips and other capabilities that form sophisticated electronic circuits. These components offer a wide range of processing and control tasks that are essential to most electronic devices.

- Inductors – The SMT inductors create a magnetic field when current flows through it, and this stored energy is useful later on. Frequently, they can be found used in the circuits that control power supplies and filters.

- Diodes and Transistors – These SMT diodes and transistors that are semiconductor devices control the current flowing through them. In terms of the electrical circuits, they are fundamental building blocks.

- Connectors – SMT connectors offer electrical connections among various components of a circuit. They have various forms like USB connectors, HDMI pins etc.

- LEDs (Light-Emitting Diodes) – SMT LEDs serve the functions of displaying information, illuminating and showing what is going on in an electronics device. They are available in both color and size.

- Switches – SMT switches comprise tactile switches and push-button buttons and serves as input control mechanisms to users in electronic devices.

- Crystal Oscillators- So, SMT crystal oscillators may be useful in microcontrollers and other applications where precise timing signals are essential.

- MEMS (Micro-Electro-Mechanical Systems) Devices – Microelectromechanical systems SMT MEMS devices consist of sensors and acts that combine electrical mechanical facilities on a small scale. The following are some examples of sensors: pressure sensors, gyroscopes, and accelerometers.

- RF (Radio Frequency) Components placement – Examples of SMT electronic components that are included in the systems intended for useage on high frequency applications include various parts such as elements like SMT antennas, filters and inductors.

- Thermal Components – Estimators Used in the synchronized decision-making processes SMT thermal components, including heat sinks and thermal pads are used together with electronic devices to aid management and dissipation of its heat.

Surface mount technology in design

The landscape of computer engineering in terms printed circuit boards PCBs and electrical circuits has evolved through the use Surface Mount Technology SMT or smt process . It is particularly influential because this technology enables miniaturizing components, thus increasing the number of parts per unit area and producing lighterand-smaller electronic assembly .

Surface-mount Technology (SMT) mounts components directly onto the surface of a printed circuit board PCB ,through hole components are not needed, hence more effective use of space is made on the PCB were you can also notice those molten solder, smaller components, solder paste volume, solder joints .

This technology is ideally suited to applications that have high frequency rates and it assists to improve signal integrity by reducing the amount of distortions as well electromagnetic interferences and its surface tension.

SMT has automated assembly capabilities, which are given to pick-and-place machines aby the manufacturing process being streamlined. This then leads to efficiency and lower cost during production were you can see the smt component packages with those thin small outline package of course it can reduce manufacturing costs on it .

The benefits Designers may take advantage of are the advantages on versatility in design, thermal capabilities and also for using a combination of surface-mount technology (SMT) together with through hole components you can also use wave soldering that can fulfill many particular circuit needs either solder paste printing, solder joints, component placement.

Modern packaging technologies, including the ability to integrate highly complex features in a smaller packing footprint is also one of the reasons for which surface mount components cannot be facilitated or and the component leads were failed components. On the whole, Surface-Mount Technology SMT has evolved as an integral part of electronic design whereby designers can create compact, efficient and high performing electronic systems.

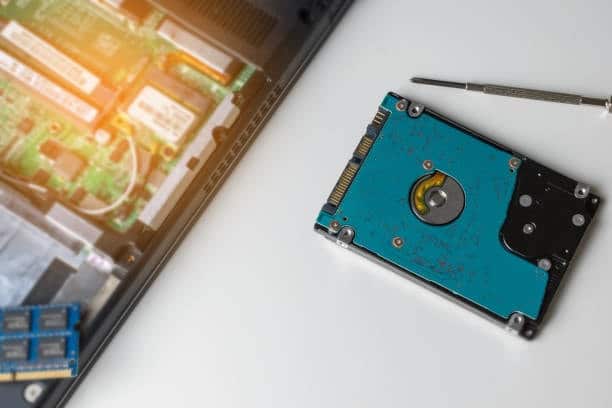

PCB assembly using surface mount technology smt components

PCB assembly, which uses Surface Mount Technology (SMT) when mounting electrical components on a printed circuit board PCB part is one of the most highly automated and simplified procedures.

Engineering begins the trip with careful preparation of architecture and circuitry that is often optimized for the use SMT components, which impresses due to their small size.

In the following stage after PCB production, a stencil is used to ensure that apply solder paste at particular points on the board’s surface in an extremely accurate manner.

The next step is going to be focused on pick-and-place machines. These machines are involved in selection of SMT components from reels or trays and placing them on solder paste coated pads called solder pads. Among other things, the assembly undergoes an important phase within a reflow oven whereby all of the printed circuit board (PCB) is heated.

This results in melting of the solder paste which then forms secure soldering junctions when after cooling off. Post-assembly inspection is provided by technologies, such as Automated Optical Inspection AOI , that assure the right positioning of components and integral solder joints.

Additional practices which may be applied include conformal coating as well s selective soldering, so it would depend on the needs that are being addressed. To ensure that the printed circuit board (PCB) meets certain criteria, rigorous testing and quality control aspects are performed which also the printer applies solder paste to the smc and solder pads. After passing quality tests PCBs, they are packaged and set up for delivery.

This is a sign of the completion of an efficient SMT based PCB assembly process that is quite known for its high degree at accuracy, speed and has sufficient power out capacity to build electronic products both compact but dependable.

Other related terms of smt components

- Through hole Technology (THT)

- BGA ( Ball Grid Array)

- QFP (Quad Flat Package)

- AOI (Automated Optical Inspection)

- PCB ( Printed Circuit Board)

- CAD (Computer-Aided Design)

- ESD (Electrostatic Discharge)

- Pb-Free (Lead-Free)

Factors to consider before choosing SMT process or THT

- SMT will work better for high volume, automated production whereas THT may be more suitable when hand assembly is required.

- SMT is more profitable for large scale, automated production whereas THT may have a lower initial setup costs. Hence, it is necessary to pay attention not only to production volumes but also early fixed costs.

- As soon as space economy is a top priority, SMT makes room for the development of tiny PCBs; however it may limit board space since THT demands more significant footprints.

- Heat dissipations requirements should also be taken under consideration; SMT may suit smaller components while THT might perform better when it comes to heat that is dissipated in bigger components.

- The difference lies in the ease of manual repair and replacing components if reparability is important; THT makes it easier to do, whereas SMT may present some challenges for manual rework.

- Speak about differences SMT is better adapt at modern, miniaturized electronics while THT fits best applications that need bulkier and more robust components.

Examples of SMT in the world

- Smartphones

- Tablets

- Flat Screen Tvs

- Laptop

- Ultrabook

- Printers

- Scanners

- Engine Control Units

- In-Car Infotainment Systems

- Diagnostic Equipment

- Implantable Devices

- Networking Equipment

- Smart Home Devices

- Avionics Systems

- Military Electronic circuits

- LED strips

- Bulbs

- Smartwatches

- Fitness Trackers

- Health Monitoring Devices

- Control system

- Power Inverters

- Smarts Sensors

Advantages and Disadvantages of the Surface mount technology

We will know that advantages and those Disadvantages of the Surface mounting technology:

Advantages of Surface Mount Technology (SMT):

Surface Mount Technology (SMT) in the field of electronic assembly becomes a desirable set of things. Due to the reason that components are directly mounted on top of the surface of printed circuit board (PCB) it helps in creating circuits which can fit into smaller spaces. As a result of this technique, it is possible to have an array with high P.C density implying that we can now miniaturize electrical equipment This fact was brilliantly incorporated throughout the essay allowing me better comprehend its meaning and nature by recognizing key characteristics such as informational vs argumentative writing in academic contexts marked In case of mass production SMT is a perfect choice for automated assembly as much makes the efficiency and saves money in all processes during manufacturing. Driven by its superior performance characteristic such as a great thermal and being compatible with the latest packaging technique, SMT has become the preferred material on high frequency applications and in modern day electronic devices.

Disadvantages of Surface Mounting Technology (SMT):

Surface Mount Technology, however fragrant and helpful it may be at first glance does come with its ugly side. Multiple operations of manual redo or repair on the SMT components are indeed small size-oriented and hence may prove to be rather challenging. Similarly, careful consideration of solder connections made using SMT must go to designs in which physical pressure will arise at some point because such attachments may succumb easily under mechanical stress. Compared to the cost of starting up traditional through-hole technology, the initial setups costs for SMT assembly lines will be significantly larger. In addition, the chances are that SMT is not suitable for uses where more power or rather large components are required. Taking such considerations into account, it is necessary to carefully scrutinize requirements peculiar to the application of either SMT One and alternative assembly methods.