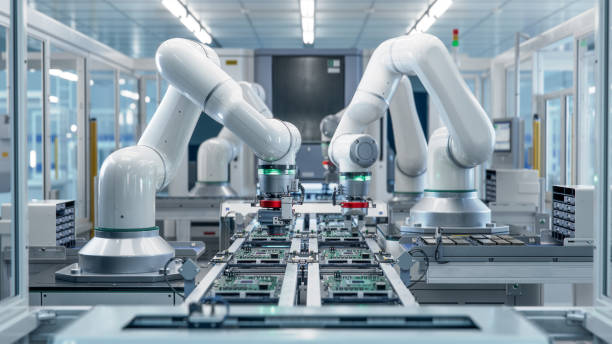

Find out the basic elements and integrated process of Robotics PCB design, which form an advanced and practical mechanism for robotic control system. supporting. Find the comments and tips that can put you on track to achieving your goals when designing a quality Robotic PCB.

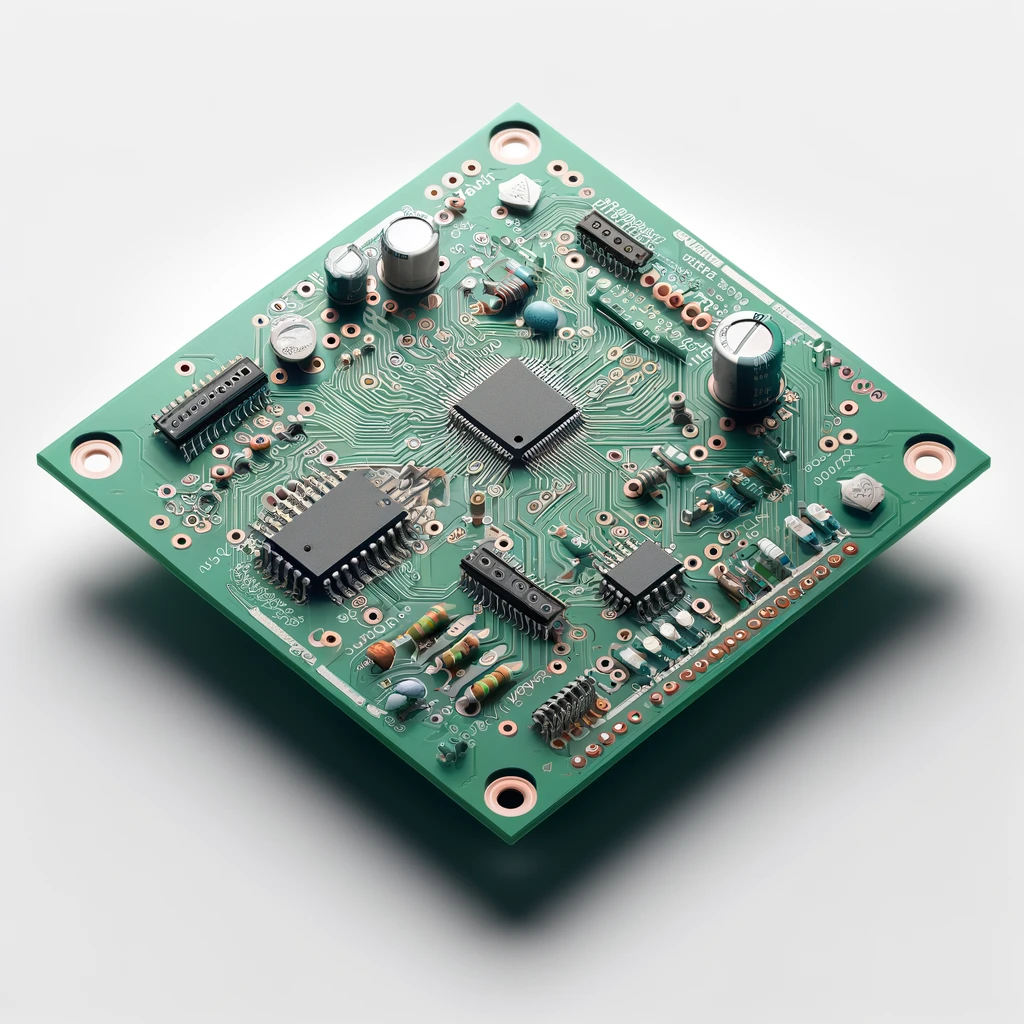

What is a robotic PCB?

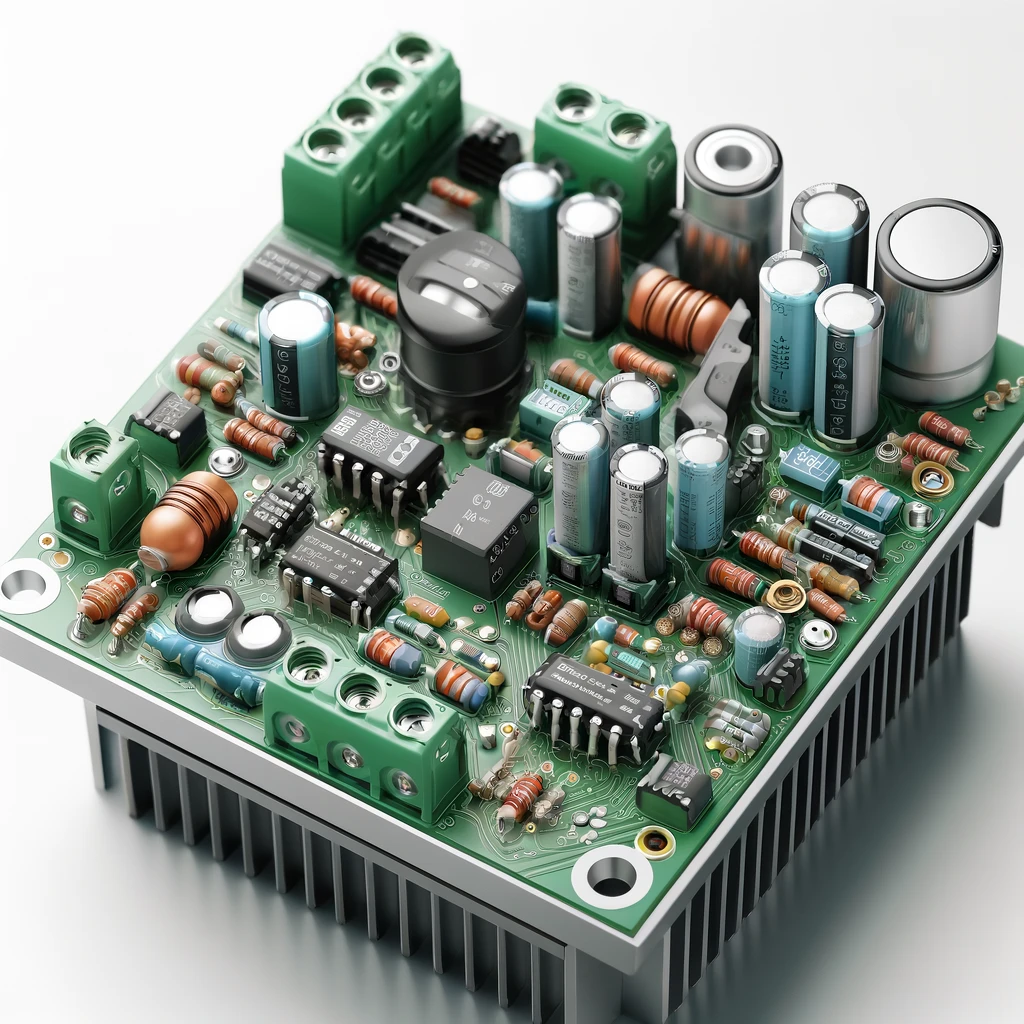

It is a highly individualized printed circuit board which is utilized in various industries, in particular with the application of artificial intelligence and robotic mechatronics. It becomes the central junction for all the remote and on-boards communications, playing side role to the multitude of electronic peripherals that include detectors, actuators, embedded controllers and flexible substrates. The PCB layout is designed in a way to meet the robot system’s effectiveness requirements, allowing free flow and electrical energy usage to be maximized. The electrical skeleton and circuit board that are robo PCBs are essential for the proper functioning of robotic systems, as they are being used to sense, process information and act by implementing corrective movements as well as tasks.

What are the Types of Printed Circuit Boards (PCBs) Used in Robotics Applications?

Robotic applications use a number of varying types of PCBs to address particular functional issues and multiple challenges. Here are some of the types of PCBs utilized in robotic automation applications:

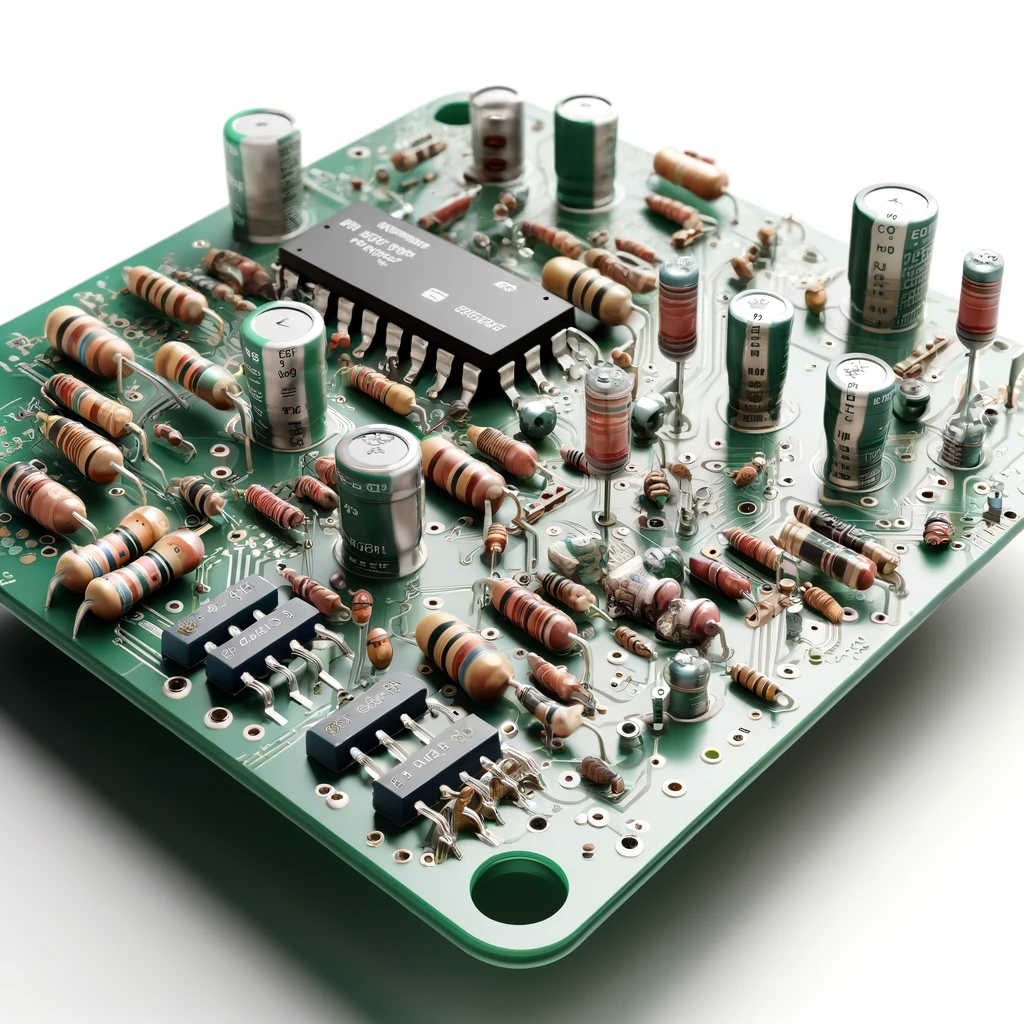

Single-Sided PCB: This type of PCB is the most commonly used one, where the parts are mounted on a certain side of the board while the traces are on the side opposite to it. They are economic in nature, and other robotic systems with no interaction are easy to deal with.

Double-Sided PCB: On the other hand, dual-layer PCBs use both sides of the board for modules and via or plated-through holes to interconnect the cures. In this aspect, they provide better module density and are therefore very suitable for robots that have to have additional functions, like manifold other robotic systems.

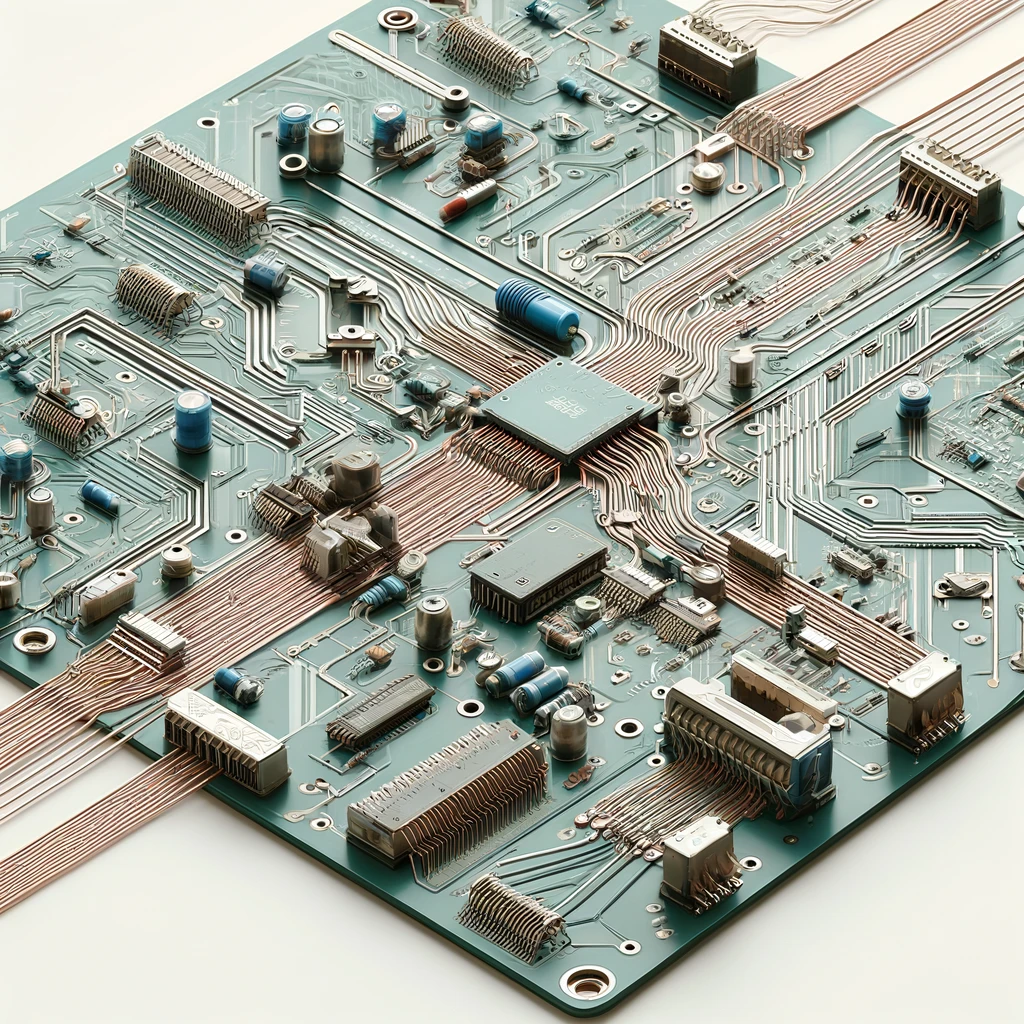

Multi-Layer PCB: The typical multi-layered PCB consists of copper foil sandwiched between the insulating layers. They come up with routes in a better way and increase signal clarity, which makes them the best choice for robotics applications where allocation is limited and signal clarity is critical.

Rigid-Flex PCB: Hybrid flexible-rigid PCBs contain a high rigidity of rigid PCBs with bending possibilities at the user-defined points. They are a good choice in the applications of robotics where harsh environments and mechanical flexibility are highly critical, which provides a better way for the construction of compact and flexible devices.

High-Frequency PCB: High-frequency PCBs are in place to prevent the to prevent the deterioration of higher-frequency signals with minimal signal loss and impedance imbalance. They are the most common in the robotics field as they involve the effortless transmission of information, detectors, and signal processors.

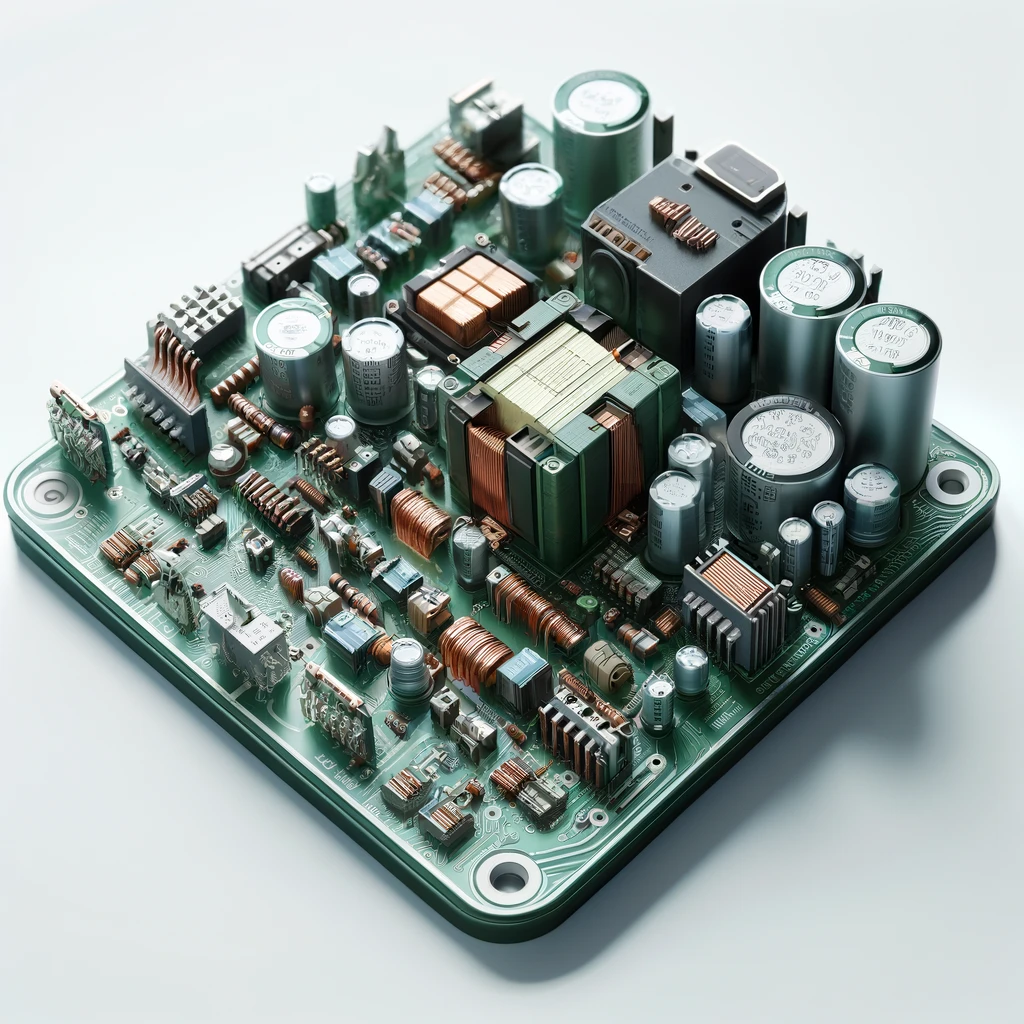

High-Power PCB: High-power PCBs are known to withstand high-energy levels of current and voltage without failure or overheating issues, thus making them more suitable for electrical energy-intensive applications. They are vital in robotics that require solid motors or actuators; this will not frustrate safety or consistency.

These are the various types of PCBs that provide unique opportunities, and hence, carefully selected boards become the right choice based on the specific requirements, capabilities, and limitations of the robotics project. Suitable for the best type of PCB, the proper choice will be designed to optimize the productivity, quality assurance process, consistency, and efficiency of the robotic system.

What are the key components used in a robotics PCB?

Work as the head of robots, the primary command center from which all functions of robots are directed. Data-soldering robots are also processed there. Supply the energy to the circuit PCB and other electronic components, mostly through batteries or power regulators. It consists of the resistors, capacitors, and diodes for analog functions of the printed circuit board, the main PCB circuit, and signal processing. Allow for interconnectivity capabilities with different kinds of devices via various protocols, which may include WiFi, Bluetooth, and Ethernet.

Microcontrollers

These are major parts of the robot, as they act as the robot’s brains, and they are the ones that manage all functions and process data input.

Sensors

They gather information either from the robot’s proxy sensors, gyroscopes, accelerometers, or cameras.

Actuators

Actuators transmit electrical energy into mechanical movements facilitated by commands from the microcontroller. Samples are the ones such as the motors, servos, and solenoids.

Power Sources

The electrical sources, usually batteries or energy regulators, may supply the PCB and the other components with the energy required.

Connectors and Interfaces

Through it all, such modules are required components to accomplish the wiring and transmission of external equipment.

Supporting Circuitry

The essential support circuitry is composed of resistors, capacitors, and diodes, which are in charge of the basic functioning of the PBC, the signal conditioning, and the safety of its modules.

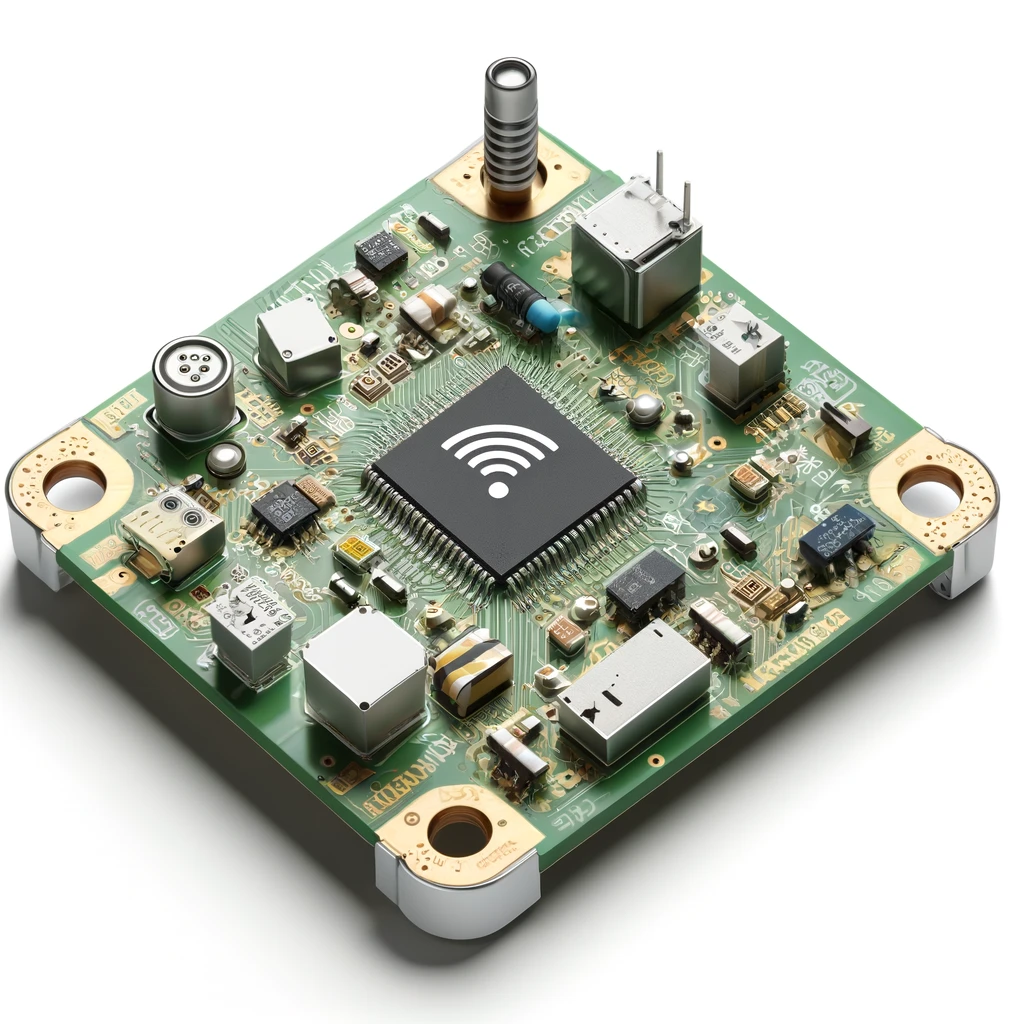

Communication Modules

Through the blocks, the robot can connect with other robots or instruments via software or networks such as WiFi, Bluetooth, or maybe Ethernet modules.

Motor Drivers

Embedded controllers are one example of the most important devices in the robot segment. They control the speed and direction of the motors that facilitate robot movement by sending signals to the microcontroller.

What is the role of electronic components in robotics systems?

They act as an essential part of the effectiveness of robotic systems through improper design, engineering, and operation, affecting their sensory, processing, and acting levels. Here’s a breakdown of their roles:

Sensing

Sensors like transducers or detectors are the specific devices in medical robots that pick up data about the robot and its surroundings. The detectors can perceive multiple physical parameters, including temperature, pressure, light, proximity of touch, and motion, to name a few. They supply the crucial data that the robot uses for navigation and understanding its environment.

Processing

The next thing is that the information provided by the transducers or detectors is handled by embedded processors and controllers, which process it. These supported peripherals take the sensor, execute the algorithms, and make decisions either based on the instructions of the model or machine learning models. Basically, they are the tools responsible for problem solving and interpreting the behavior of external objects.

Actuation

An actuator is defined as an electron device moving in a way or a manipulation process. They are what move the machine, and they are effectively motors that translate the electrical signals of the microcontroller into mechanical motion. The actuator examples include motors, servos, solenoids, and pneumatics. Servo motors let robots interact with their environments by doing routine repetitive tasks such as movement, capturing objects, handling instruments, and so on.

Communication

Electronic peripherals such as sensors, actuators, and control circuits enable coordination of activities amongst various robot parts and with external devices or networks. Communication can be implemented through wired means, for example, through Ethernet or USB ports, and wireless communication protocols such as WiFi, Bluetooth, etc., as well as RFID. Connectivity allows robots to send and receive data, follow orders, and collaborate with other robots, systems, or devices.

Power Management

The electronic circuits require components and peripherals that, in addition, become important devices used for different kinds of power management in robotic systems. There are several electrical sources for energy, such as batteries and electrical regulators, which not only provide the power but are also used for regulating the electricity as well as for electrical energy distribution and conversion.

What are the specific considerations for robotic PCB manufacturing?

When manufacturing PCBs for robotics applications, there are several specific design considerations that must be taken into account to ensure the reliability, effectiveness, improper design, and functionality of the printed circuit boards and final product. Here are some key factors:

- Component Placement and Orientation: Proper part positioning and PCB’s orientation are necessary steps, as your example requires, to ensure the system’s full performance and compatibility with the entire robotic system. There are different components that should be placed based on the location inside the satellite in a way that does not interfere with the signals, create thermal issues, or create a mechanical constraint.

- Robustness and Durability: Robotics environments turn out to be very harsh because of the PCB manufacturing vibration, shock, temperature fluctuations, and high humidity levels. Consequently, the PCB layouts have to be engineered and crafted with a specific focus on the extreme environments they are going to be put through. The selection of quality materials, among other aspects like a sound soldering tip technique and even reinforcing critical parts of the board, is included.

- Size and Form Factor: For robotics, PCBs usually have a choice of size and shape to be considered owing to the lack of sufficient accommodation in bots and robotic systems. The manufacturers should be able to arrange the processing-computational block (PCB) so that it comfortably accommodates all the additional peripherals but limits the total occupied allocation. The space may be made use of more effectively in this regard through such approaches as multilayer PCBs or rigid-flex designs.

- Signal Integrity: Signal integrity is one of the paramount concerns of the well-constructed robotic board design, since reliable connection is a must between all parts. Various elements, which consist of trace routing, impedance matching, and noise cancellation techniques, must be addressed to reduce signal degradation, electromagnetic interference (EMI), and crosstalk.

- Power Management: Proper energy management, where necessary in the manufacturing industry, is a critical step to the proper and perfect distribution of electrical energy and regulation. This includes the wise use of energy sources, more effective jobs through energy-saving features, and batteries aimed at the best distribution network with limited consumption but maximum life.

- Manufacturability and Testing: PCB creation needs to be built to the scale of mass production and the overall tests to achieve quality and reliability Engineers are expected to corroborate production principles such as manufacturing tolerance, assembly process and testability features during the design, which so far is a way to upgrade production process and streamline system testing and debugging.

- Compliance and Established Standards: Designing PCBs should probably be the same whether it is relevant to strict dimensions and regulatory requirements and it varies according to the final use. Standards like safety certifications or EMC/EMI compliance can be necessary depending on the application and the market at the same time. Companies shall implement quality assurance measures for PCBs for robotics design such that their products are in compliance with the required standards and safe for use.

What are the Designs and Integrations of Power Supply Systems in PCBs for robotics?

The process of developing an electrical power supply Printed Circuit boards (PCBs) in robots require precision the integration of the raw materials into the parts and precision construction of specific elements to guarantee the reliability and efficiency of electrical energy distribution. Here’s an overview of the key aspects:

- Voltage Regulation: similarly, the electrical energy supply system integrates voltage regulation elements that keep the voltage release consistent, as well as well established for the rest of the circuit, the PCB and the interconnected components.

- Power Source Selection: There are multiple challenges of different engines; for instance, robotic PCBs and software are powered by batteries, AC mains, or any other multiple resources. The intended electrical energy supply system must be built taking into account the chosen electric energy source and incorporating all suitable protective circuit equipment like overvoltage and undervoltage fuse and reverse polarity.

- Efficiency Optimization: Efficiency is the most important feature in robotics applications, which comes from increasing the measure of the remaining battery charge that is possible during a specific period of time and sparing the energy during this period. In order to get great outputs from electrical energy supply of medical robots, we should use electrical energy management strategies and high-quality energy-saving components.

- Current Handling: Robotics equipment is no exception, and the routing of high bus currents to motors, actuators, and other high-load PCB components requires special attention. Electrical energy delivery constructs should be designed with the required current values in mind, ensuring safe and efficient conduction processes as well as applying current and overflow protection equipment.

- Heat Dissipation: During the operation of open circuits, electrical energy materials not only are a source of heat but also intensify this effect, particularly in high-current applications. Good thermal management is the key to keeping the equipment cool and unwanted shutdowns of the system away.

- Integration with Control Systems: The energy systems must be thoroughly managed and controlled through the general computer system that runs every part of the robot. This can be achieved by equipping processor systems with interfaces to embedded controllers and other control units so that electrical energy management and monitoring functions for various industries can be integrated.

- Compact and Space-Efficient Design: Space, in most robotics applications, is constrained, and this, in most cases, implies that power systems shall be designed with a small size and a compact and novel space-efficient layout. Here, the power supply system may be built using multi-layer PCBs or flex-rigid designs that can help in increasing space utilization.

What are the strategies for effective integration of electronic components?

The type and placement of electronic circuit boards and component integration are vital factors in improving the performance, dependability, and manufacturability of robotics industry electronic circuit boards. Here are some strategies for achieving efficient integration:

- Modular Design: Apply a modular design methodology for the system design by dividing it up into smaller, inter-changeable subsystems or modules. It enables the expected functions but also ensures easier integration, testing, and other third-party maintenance services for individual components.

- Component Selection: Concentrate on choosing the standardized components and the ones that are compatible so that the integration is smooth and the design is simple. Consider availability, reliability, and dependable long-term support when making choices regarding components of your design.

- Component Placement: Thoroughly rationalize the layout of electronic components on the PCB board so as to decrease signal interactions, heat dissipation, and routing difficulties.

- High-Density Packaging: Employ high-density packaging techniques in the form of SMT and BGA to maximize the small area being needed for components to be placed on the PCB.

- Routing Optimization: Configure the PCB routing to minimize the impedance mismatch, EMI, and crosstalk. Closely adhere to trace to keep high-speed signals short and connect ground and power planes effectively to result in signal integrity and lower noise levels.

- Design for Manufacturability (DFM): Manufacturing ease can be pursued already in the design stage; that way, not only assembly of the product becomes easier but also cost-effective production is achieved. Utilize the board layout to match a standard appearance and also make it more assemble-friendly by adding assembly-friendly features, which helps to shorten the manufacturing process and reduce the penalty for errors.

- Thermal Management: Utilize thermal management approaches like heat sinks, thermal vias, and fan cooling that will remove excess heat from devices and stop the CPU from overheating. Since this prevents thermal strain during long hours of work, this contributes to the long-term reliability of the PCB.

- Testing and Validation: Create a full suite of testing and verification methods throughout the design cycle to spot issues concerning integration and give a possible solution. Testing the functionality and efficiency of assembled electronic blocks by means of simulation tools and prototyping in production before an industrial level.

Through the means of these engineering methods, flexible electronics components would be fabricated into flexible PCBs satisfactorily for robotics applications, which would contribute to the stability and manufacturability of the final product by ensuring quality performance.

Conclusion

Careful integration strategies allow for the best results in the field of robotics PCBs because this ensures all the PCBs’ parameters, including performance, reliability, and manufacturability, are perfect to give easy access to all the necessary information to the embedded control system to be able to make quick decisions. As robotics technology continues to be a perfected art, integration and PCBs become ever more critical, with unequivocal prospects of being instrumental in creating imaginable robots for diverse purposes, ranging from manufacturing industries to healthcare, space exploration, and whatnot.

In general, the role of PCBs must be emphasized in the manufacturing of current robotic systems and their full integration with other components. While Ethernet ports and wireless networks provide connectivity to the robot and its surroundings, PCBs work as the main platform for robotic electronics to reside and work anywhere in robots. These identifiers, actuators, microcontrollers, and power management systems are the heart that makes all robotic operations possible.

Careful integration strategies allow for the best results in the field of robotic PCBs because this ensures all the PCBs’ parameters, including performance, reliability, and manufacturability, are perfect to give all the necessary information and feedback to the embedded control system to be able to make quick decisions. As robotics technology continues to be a perfected art, integration and PCBs become ever more critical, with unequivocal prospects of being instrumental in creating imaginable robots for diverse purposes and industries, ranging from manufacturing to healthcare, space exploration, and whatnot.