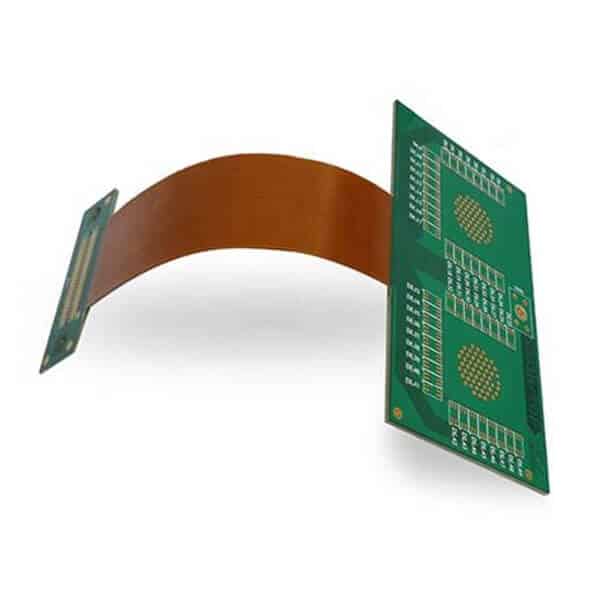

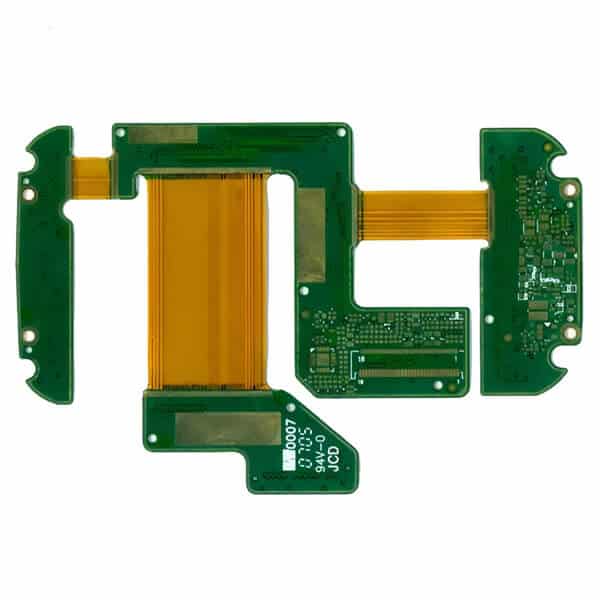

Rigid-Flex PCB

What is a Rigid-Flex PCB

Rigid-Flex PCBs integrate the robustness of rigid PCBs with the adaptability of flexible circuits, allowing for dynamic electronic designs that fit into tight spaces or require complex shapes. This technology facilitates more compact devices by eliminating the need for multiple connectors and reduces the risk of connection failures, enhancing product reliability. They’re particularly beneficial in industries where device miniaturization and reliability are critical, such as aerospace, medical, and consumer electronics. Rigid-Flex PCBs represent a significant advancement in PCB design, offering a versatile solution for challenging engineering requirements.

Rigid-Flex vs. Rigid PCBs

Rigid-Flex PCBs offer a design complexity that goes beyond traditional rigid boards by utilizing 3D space, allowing designers to fold, twist, and roll the flexible parts to fit specific shapes within a device’s final form. This capability for three-dimensional design provides greater spatial efficiency compared to rigid PCBs, which are limited to a flat, two-dimensional plane. Rigid-Flex technology thus enables more innovative and space-efficient layouts, making it ideal for applications where space is at a premium and flexibility is required.

Unveiling Kingsignal’s Rigid-Flex PCB Manufacturing Excellenc

Empowering your innovations with our advanced Rigid-Flex PCB manufacturing capabilities, where precision meets flexibility

Surface Finishes:

- ENIG

- Electric gold

- IM-Ag

- Electric Ag

- HASL

- HASL-LF

- IM-Sn

- Electric Sn

- OSP

- Caborn

- PtNI-Pd-AU

Standard flex materials:

- Polyimide (Kapton) 0.5 mil to 5 mils (.012mm – .127mm)

- Adhesiveless copper clad base material 1 mil to 5 mils

- Flame retardant laminate, base material, and Coverlay

- High performance epoxy laminate and prepreg

- High performance polyimide laminate and prepreg

- UL and RoHS compliant material on request

- High Tg FR4 (170+ Tg), polyimide (260+ Tg)

PCB attributes

Rigid-flex

Flex

Min Layer Count

1

1

Max Layer Count

32

12

Min Core thickness

.002″ (.051 mm)

.001″ (.025 mm)

Max Finished Copper Weight (I/L)

3 oz (89 ml)

2 oz (59 ml)

Max Finished Copper thickness (O/L)

9 micron (.009 mm) (only for O/L)

12 micron (.012 mm)

Max Panel Size

12×18

12×18

Smallest Mechanical Drill Diameter

.0071″ (.180 mm)

.0079″ (.201 mm)

Smallest Laser Drill Diameter

.005″ (.127 mm)

No

Min Finished Hole Size

.006″ (.152 mm)

.006″ (.152 mm)

Max through Hole Aspect Ratio

10:1

10:1

Max Blind Via Aspect Ratio

.75:1

.75:1

Min Trace and Space

≥ .0035”(.089 mm)(rigid)

≥ .0035”(.089 mm)

Min Pad Size for Test

.005” (.127 mm) (rigid)

.016″ (.406 mm)

Process Pad Diameter

D + .014″ (.356 mm) (1-mil (.025 mm) annular ring)

D + .014″ (.356 mm) (1-mil (.025 mm) annular ring)

Stacked Vias

No

No

Min Wire Bond Pad Size

> .006″ (.152 mm)

> .006″ (.152 mm)

Controlled Impedance Tolerance

5%

10%

Solder Mask Registration

Within .002″ (.051 mm)

Within .002″ (.051 mm)

Solder Mask Feature Tolerance

.001″ (.025 mm)

.001″ (.025 mm)

Solder Mask Min Dam Size

.001″ (.025 mm)

.004″ (.102 mm)

Min Diameter Route Cutter Available

.024″ (.610 mm)

.019″ (.483 mm)

Mechanical Routed Part Size Tolerance

.010″ (.254 mm)

.003″ (.076 mm)

Bow and Twist Tolerance

As per spec

N/A

Thickness Tolerance

10%

+/- .002″ (.051 mm)

Sequential Laminations

2

N/A

Buried Vias

Yes

Yes

Blind Vias

Yes

Yes

Conductive Filled Vias

Yes

No

Non Conductive Filled Vias

Yes

No

Surface finishes

Rigid-flex

Flex

HASL (Vertical or Horizontal)

Yes

Yes

Lead Free HASL

Yes

Yes

OSP (Shikoku F2)

Yes

Yes

OSP (Entek)

Yes

Yes

ENIG (Electroless Nickel/Immersion Gold)

Yes

Yes

Immersion Silver

Yes

Yes

Immersion White Tin

NO

NO

Tin Nickel

NO

NO

Electrolytic Soft Gold

Yes

Yes

Electrolytic Hard Gold

Yes

Yes

Selective Gold

Yes

Yes

Solder mask colors

Rigid-flex

Flex

Amber

Yes

Yes

Green

Yes

Yes

Black

Yes

No

Red

Yes

No

Blue

Yes

No

Yellow

Yes

No

White

Yes

No

Clear

Yes

No

Bright White

Yes

No

Purple

Yes

No

Legend

Rigid-flex

Flex

White

Yes

Yes

Fab

Rigid-flex

Flex

Routed Array

Yes

Yes

V Score, Edge to Copper

.01″ (.254 mm)

.002″ (.051 mm)

V Score Angles

Yes

No

Countersink

Yes

Yes

Counterbore

Yes

Yes

Bevel

Yes

Yes

Milling

Yes

Yes

Edge Castellation

Yes

Yes

Edge Plating

Yes

Yes

Heatsinks

No

No

Electrical test

Rigid-flex

Flex

10 Volt

Yes

Yes

40 Volt (Burn-In Boards)

Yes

Yes

250 Volt

Yes

Yes

500 Volt

Yes

Yes

Laminate materials

Rigid-flex

Flex

Flexible Poyimide

Yes

Yes

Arlon 85NT

No

No

Bergquist

No

No

Hybrid Constructions

Yes

Yes

Isola FR406

Yes

Yes

Isola FR406

Yes

Yes

Isola FR408 HR

Yes

Yes

Isola P95

Yes

Yes

Isola P96

Yes

Yes

Iteq IT180

Yes

Yes

Panasonic R1766

Yes

Yes

Panasonic R1755

Yes

Yes

Panasonic Megtron

Yes

Yes

Nelco N4000-13

Yes

Yes

Nelco N4000-29

Yes

Yes

Nelco BT N5000

Yes

Yes

Nelco N7000-2

Yes

Yes

No Flow Prepreg

Yes

Yes

Isola 370HR

Yes

Yes

Isola 370HR

Yes

Yes

Polyclad Getek

No

No

PSA Bond Film

Yes

Yes

Rogers 3000 Series

No

No

Rogers R4000 Series

No

No

Rogers 5000 Series

No

No

Rogers 6000 Series

No

No

Rogers TMM

No

No

Available reports

Rigid-flex

Flex

Microsection

Yes

Yes

Solderability

Yes

Yes

X-Ray Fluorescence

Yes

Yes

Ionic Contamination

Yes

Yes

Time Domain Reflectometry Test (TDR)

Yes

Yes

FAI

Yes

Yes

Certificate of Compliance

Yes

Yes

UL

Rigid-flex

Flex

94VO

Yes

Yes

PCB classifications mil-spec

Rigid-flex

Flex

MIL-PRF-55110

No

No

MIL-PRF-31032/1

No

No

MIL-PRF-31032/2

No

No

IPC 6012, Class 1, 2 and 3

Yes

Yes

ISO 9001:2015

Yes

Yes

ISO 13485:2016

Yes

Yes

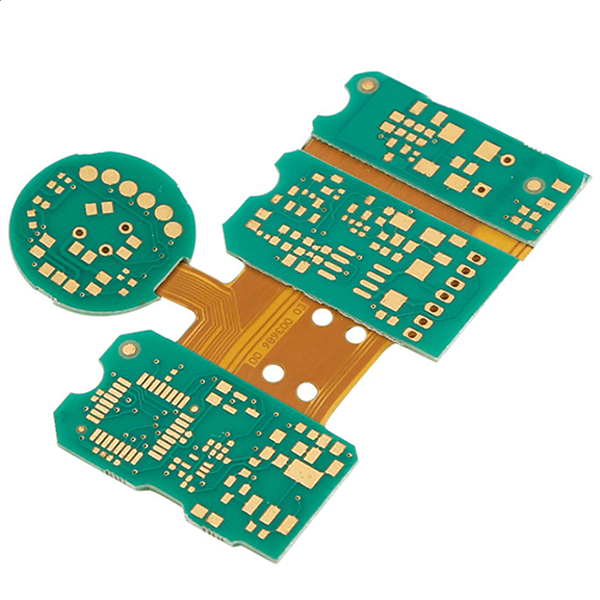

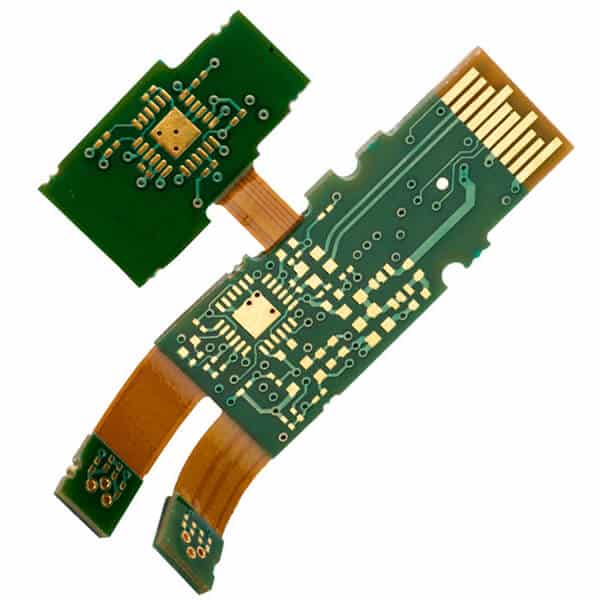

Showcasing Our Rigid-Flex PCB Innovations

Rigid-Flex PCB Applications Unveiled

Rigid-Flex PCBs are integral in sectors demanding compact, efficient designs. Their unique structure supports innovations in wearable tech, medical devices, and aerospace, allowing for devices that bend, fold, or curve. This adaptability is crucial for modern, sophisticated electronics, pushing the envelope in design and functionality.

Moreover, consumer electronics and automotive industries benefit significantly from Rigid-Flex PCBs. They enable sleeker, more reliable products by minimizing space and enhancing durability. This technology’s role is pivotal in developing future electronics, from smart wearables to advanced automotive systems, demonstrating its vast application spectrum.

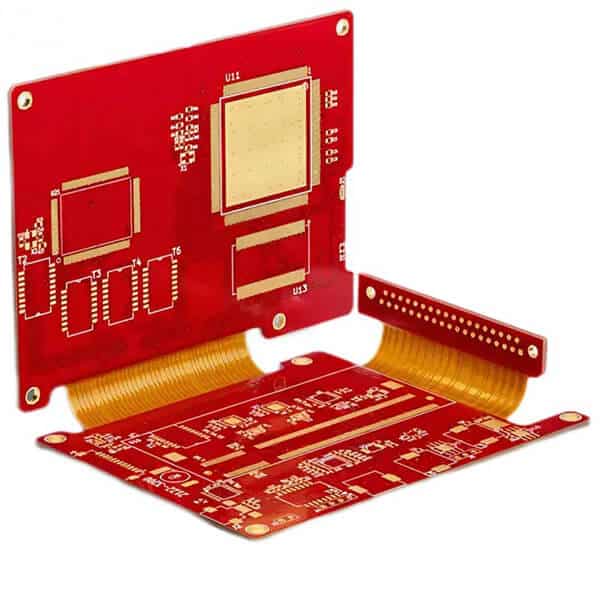

Mastery Behind Rigid-Flex PCB Technology and Production

Rigid-Flex PCB technology combines the durability of rigid boards with the adaptability of flex circuits, offering solutions for prototypes and mass production that address space and weight limitations. Early collaboration with fabricators in the design phase can significantly enhance product outcomes, optimizing the integration of design and manufacturing insights for superior functionality.

The manufacturing process for Rigid-Flex PCBs is intricate, requiring specialized handling and processing techniques distinct from traditional rigid board fabrication. This complexity ensures that each component meets the highest standards of quality and reliability, underscoring the advanced craftsmanship involved in bringing Rigid-Flex PCB designs to life.

Benefits of Rigid-Flex PCBs

- Space Efficiency: Enables compact designs by integrating flexible and rigid sections into one board.

- Reduced Weight: Lighter than traditional PCBs, beneficial for portable devices.

- Enhanced Reliability: Fewer solder joints and connectors reduce potential failure points.

- Design Flexibility: Can be folded or twisted, offering creative design options.

- Improved Aesthetics: Seamless integration contributes to sleeker device profiles.

- Cost Savings: Reduces assembly costs by eliminating the need for multiple boards and connectors.

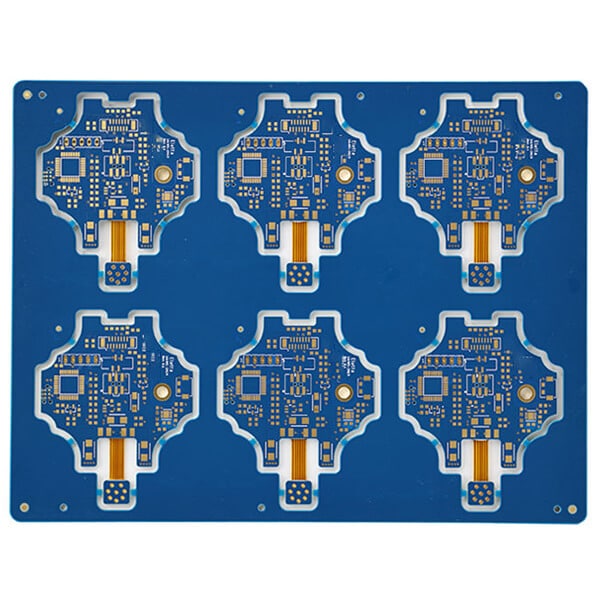

Why Choose Kingsignal for Your Rigid-Flex PCB Production Needs

Choosing Kingsignal for your Rigid-Flex PCB production means partnering with a leader in quality and performance, located in a state-of-the-art 100,000 square foot facility in Jiangxi. Our advanced equipment supports the manufacturing and assembly of standard quick-turn PCBs and Rigid-Flex boards with the strictest tolerances, utilizing special metals for superior results. Kingsignal’s commitment to excellence ensures your projects meet the highest standards in the industry.