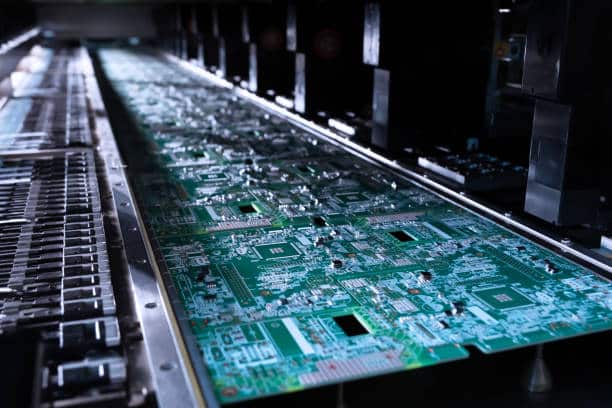

Circuit Board LED in Industry

What is led pcb?

PCB or a LED printed circuit board is a kind board that supports LEDs, light-emitting diodes. Main concepts related to thermal management LED PCBs comprise of their heat dissipation ability which extends longevity and function of metal core pcbs. Furthermore, LED PCBs are integral components target towards uniform light distribution, hence it gives the impression of improved lighting effect or improved heat transfer. LED PCB located in LED light systems ensures integrity and reliability of all lighting systems, residential or in use for heavy-duty tasks.

What are the advantages of led pcb board?

LED PCB boards offer several advantages over traditional PCBs, particularly when used for lighting applications:

Efficient Thermal Management – LED PCBs have thermal management being their main decisional factor allowing them to heat the LEDs efficiently. That, on the other hand, raises the service life of the LEDs.

Compact Design -An LED PCB has the ability to be designed to a very small footprint, which makes the PCB suitable for use in applications in which there is limited space available.

Enhanced Durability -LED PCBs are usually known to be able to withstand harsh conditions more than traditional PCBs; therefore, that is the reason why they are used in such tough conditions.

Energy Efficiency -LEDs are often rated as super energy savers, needing only a fraction of the electricity that incandescent bulbs require. This approach leads to energy savings and can be cheaper in the long run.

Customizable -Unlike other methods LED can be formed into various patterns to fit various lighting application.

Long Lifespan -With LED lights having a much longer life span than traditional sources of illumination, there is a clear advantage in there being a need for frequent replacements and repairs.

Environmental Benefits – The LED PCB are eco-friendly, they don’t release dangerous material (mercury) into the environment like most conventional brake lights do. Additionally, they are recyclable.

What are those factors to consider when designing an led printed circuit boards?

With the premeditated assessment of the mentioned factors during the design process, you get a quality LED PCB that assures a complete performance, efficiency, and the reliability required for your particular intended use. Designing an LED printed circuit board (PCB) requires careful consideration of several factors to ensure optimal performance and reliability:

LED Selection

It is necessary that you select LEDs with the following criteria, such as brightness, color temperature and forward voltage/current ratings relating to your application.

Thermal Management

On the PCB, provision enough of heat sinks and ventilation so that heat produced by the LEDs is dissipate heat properly and the LEDs are operated in their suitable temperature limit ensuring optimal performance and reliability.

Layout and Placement

Place the LEDs on the circuit board in order to create the appropriate lighting coverage and avoid shadowing of the circuit components. Examine the beam angle and the LED positioning to ensure appropriate and consistent illumination.

Power Supply

Choose the power source that can support the voltage and current that the LEDs will need, and make sure the PCB layout considers the connections of power supply along with the heat dissipation demands or a high powered led lights.

Circuit Design

By using well circuit design techniques to ensure measurable and reliable performance, current-limiting resistors, bypass capacitors, and correct grounding should be applied.

Protection Circuitry

Incorporate protection circuitry, e.g. overcurrent protection and reverse polarity protection, to prevent enough damage to LEDs from power surges and other electrical faults.

Environmental Considerations

Ensure that the PCB can withstand environmental factors for example temperature, humidity and vibration in order to extend the durability of the system in different circumstances.

Manufacturability

Look at manufacturability in the planning stage of designing the PCB, such as size of PCB, component placement, and assembly processes, to provide ease of manufacture and reduce the production cost.

Testing and Validation

Proceed to the pcb layout design testing and validation procedures to guarantee that all performance specifications and reliability requirements are met before production.

What are the benefits of led lighting?

Energy Efficiency – LEDs spend a lot of less energy as compared with the conventional incandescent and fluorescent bulbs thus save lots of electricity expenses and minimize the greenhouse gas emission.

Longevity -LED’s can stay functional up to twenty five times more than traditional bulbs and thus maintenance cost is limited as well as the amount of cause of hindrance.

Low Heat Emission – LED’s give away a minimum amount of heat sensitivity, so that they are safer to use and reduce the cooling load in air conditioning systems.

Color Options and Dimming – Due to the fact that LEDs have multitude of colors and can be dimmed, lighting design is promoted and the ambiance becomes more versatile.

Environmentally Friendly – LEDs have no toxic substances and are fully recyclable, so this makes them environmental considering.

Instant Lighting – LEDs switch the light on fast, unlike other types of bulbs, which need lighting time to warm up.

Durability – LEDs are extremely durable to resist shocks, vibrations, and exposures to impacts.

Design Flexibility – The LEDs are owing to their flexible nature and can be configured in different shapes and various sizes which facilitate development of creative and particularly interesting lighting concepts.

What are those challenges of led lighting?

Upfront Cost – While LED fixtures and bulbs are often pricier initially than traditional lighting options, their price has been going down, and more than that they pay for themselves over time.

Quality Concerns – One hitch of low-quality LEDs may be the problem of color inconsistency, flickering, or early failure. That is why when buying, you should always choose high-quality brands.

Heat Management – Though LEDs have living heat, LED thermal management or thermal heat sink is required to maintain the efficiency of the bulbs and the longevity of their life or heat transfer capabilities.

Compatibility – LEDs could encounter limitations such as the dimmer switch or dimmable bulbs might not be compatible with existing fittings. Therefore, upgrades to the dimmers or the fixtures might be needed for the dimming function.

Light Pollution – LED lighting, although, if unshielded or improperly directed can lead to light pollution which can prove detrimental to the ecosystem and human health.

Color Rendering – Some LED lights certainly produce hues that are not as lifelike as the ones produced by incandescent bulbs. This can then affect the look of the objects, and of the surrounding environment.

Electronic Waste – Despite being more energy efficient, LED lamps do contain components that may have an impact on the amount of electronic waste material. This makes the practice of sustainable disposal even more vital.

What is aluminum pcb leds ?

Aluminum PCB LEDs are LEDs that are mechanically on aluminum led PCBs. Thermal conductivity of the Aluminum boards is one of their main features that helps to remove heat accumulated by the LED circuit board. Therefore, the efficiency of LEDs is enhanced and the lifespan and quality of services is maintained.

For the tough mechanical properties and the durable structure provided by the aluminum based led pcbs, these PCBs are the adequate type to be used in an extreme application. Aluminum Printed Circuit Boards LED (PCB LED) with built-in heat-conducting features are widely applied in power LED lighting increasingly popular lighting solution, especially automotive, road and industrial lighting, which requires excellent thermal management. In general, aluminum effectively accommodates LEDs to display a good luminous efficacy for different products aluminum base metal or aluminum alloy base.

Aluminum pcb leds and the led lighting industry?

Copper Plated Aluminum (PCAB) LEDs occupy a special place in The LED lighting industry, which helps getting rid heat and provides ideal environment for LED operation, which leads to its increased life time. The ability of CSPs to correctly deal with heat with thermal management properties makes them perfect for high-power applications, where heat can negatively affect performance.

However, the key is that their adaptability and reliability match a few of the lights for any variety of lighting applications which ensure growth and progress of the industry. In fact, LED circuit boards aluminum assembly is the core of the technology offered by LED lighting industry. The technology provides reliable and energy-efficient lighting solutions.

BENEFITS OF ALUMINUM PCBS FOR LEDS

Aluminum PCBs provide several advantages for their use with LEDs:Aluminum PCBs provide several advantages for their use with LEDs:

Better value – Aluminum arises out of production expenses in both of the given avenues. Aluminum, when compared to other metals, is exactly what you need if you are on a budget. Opting for copper foam circuit boards that use this as their core element can stop the design from using costly heat sinks to provide thermal regulation.

Recyclable – Aluminum has the utmost degree of recyclability and is absolutely safe in use.

Durable – In spite of having similar properties with Aluminum, graphene, glass fiber, etc, the lifespan of printed circuit boards made from aluminum is much longer than that of glass and ceramic ones, even in the presence of impact damages and heat.

Lightweight – Due to the fact that aluminum is the only environmental core that will not have extra weight, boards made from aluminum are lightweight compared to the boards with core from other materials. Rather than weighing the reserves down, the lighter aluminum core helps to cut shipping and handling costs.

Improved heat transfer – Aluminum PCB cores are characterized as the one having higher thermal conductors as compared to the other processes or materials and it can prevent the LED components from heating.

Why Choose Us?

At Kingsignal Circuit Co., Ltd., we are the masters of Aluminum PCBs manufacture, which considering your special needs on the critical projects, it can handle them just right. A team of experienced specialists guarantees so that each PCB is manufactured, keeping in with the finest standards of quality and reliability, providing you with the assurance you need, and the exceptional performance you deserve. With the help of our vision of innovation and client satisfaction, we are a high-quality and brand partener of you in making of the aluminum PCB.

Innovation and Reliability: Have you ever thought it might be easier to differentiate your project from those of others by using the latest advances in LED PCB board technology? Well, we have dedicated ourselves to doing just that.

Experience and Expertise – Our knowledge in the parts of this industry is more than a decade, this amounts to the fact that we have the technical skills to design PCB boards that are in line with and more than what you would expect.

Commitment to Quality – We stay strong and you stay strong through the LED PCB for lighting as it guarantees constant brightness for a long time to come of your lighting improvements.

Customer Satisfaction – Your unwavering satisfaction is our prime goal and we ceaselessly work and strive to ensure that you are content with our products and services.

Innovation and Reliability – We keep innovating in this area to give you the most updated knowledge in the LED PCB board technology, and for this reason your projects will look good in comparison to the others.