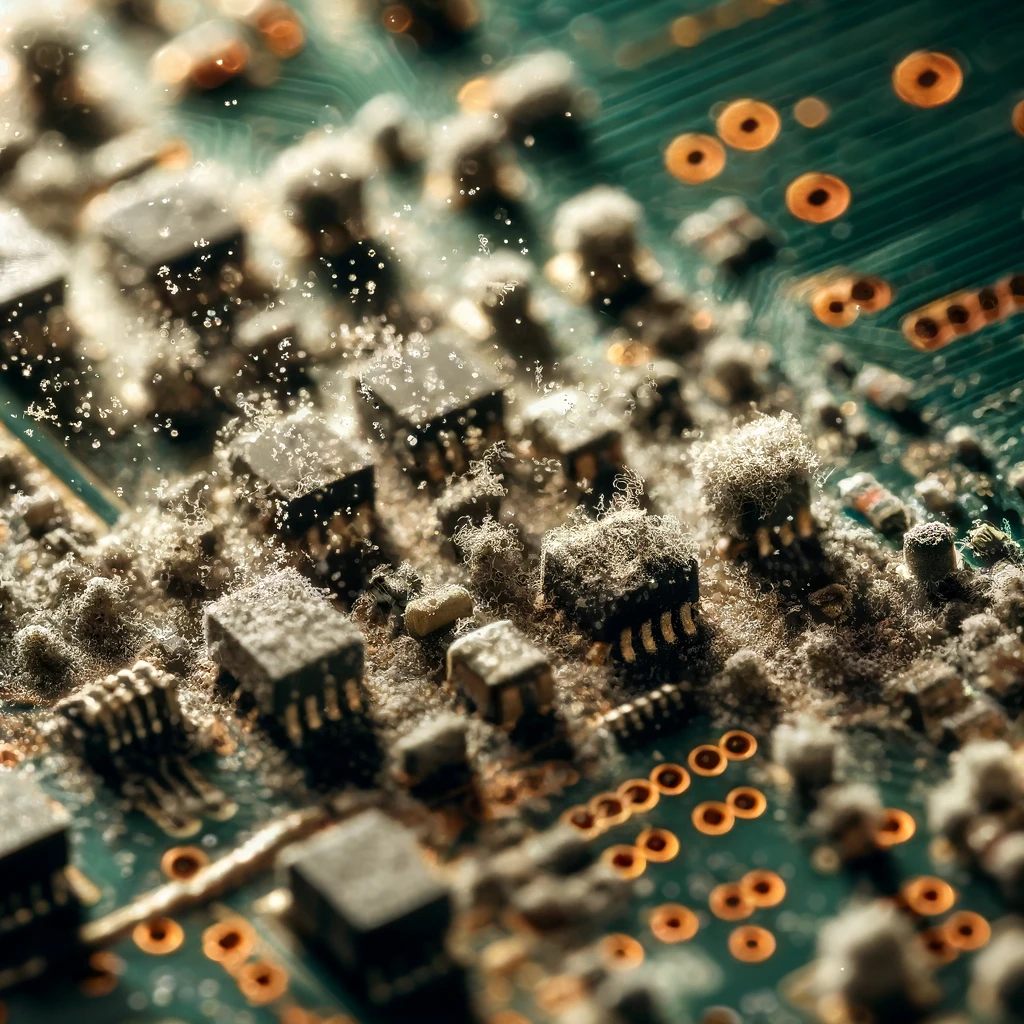

Behind every electronic device is a circuit board, which is responsible for everything from powering a phone call to speeding up computer operations. As the years go by, dust, dirt, and other pollutants will be inside the boards, ultimately leading to their malfunction or breakdown. Failure to follow the proper cleaning and maintenance procedures can destroy your PC and appliances, leading to higher replacement costs.

In this article, I will provide you with the right procedures for pcb cleaning up your circuit boards in a way that is not only safe but also effective.

Understanding Circuit Boards

It is commonly known as printed circuit boards (PCBs), or circuit boards; they are essential components in electronics nowadays. They form the basis for the electronic circuits that allow for the interconnection of many electronic components, enabling their combined operation. In this manner, knowing the basic parts and structure of a circuit board allows you to easily comprehend their significance as well as how they function.

How do clean dust and dirt from printed circuit boards?

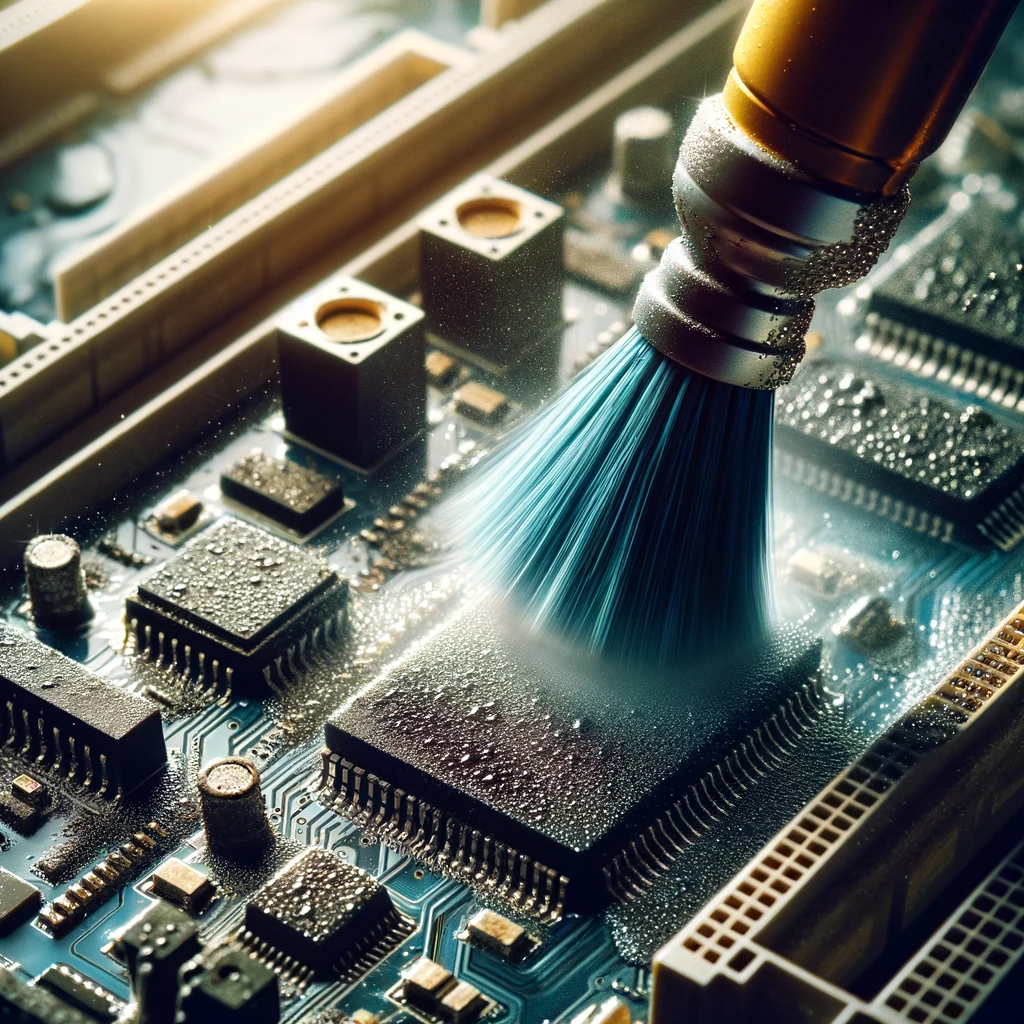

Wiping dust and pollutants from printed circuit boards (PCBs) is a mandatory procedure in case of electronic items. The first step to cleaning a PCB is to switch off the device and unplug it should any electrical shock occur. Use blasting can of compressed air to draw out the loose dust and dirt; do not tilt the can too much to keep the liquid from spreading on the board.

If that is not enough, use a cotton swab dipped in isopropyl alcohol and rub gently the parts where residual dirt or grease is present. With the use of a soft brush, we will do the final job of removing any more dust or dirt. Let the PCB dry well in air before you rebuild the electronic device. The wiping of PCBs with regular intervals not only prevents system performance issues but also helps to prolong lifespan of your electronics.

How do clean circuit board?

Cleaning the circuit board is a demanding job that requires caution to ensure the components of the circuit board are not damaged. Firstly, do cut off the power supply to avoid the risk of electrocution. In order to get rid of the dust particles and any other kind of debris, use a pressurized can of air to blow away the dust.

If there is some dirt or hard-to-remove grime, use a soft-bristled brush or cotton swab and dip them in an isopropyl alcohol and distilled water mixture to gently clean the whole surface. However, be sure to use gentle force without the use of abrasive materials, as this may result in damage to the board. Once the board is dry, have another round of compressed air cleaning to remove any remaining moisture. Before reconnecting the unit, please let the board air-dry thoroughly. The pcb cleaning process of circuit boards is another factor for the rise in performance and extension of lifespan.

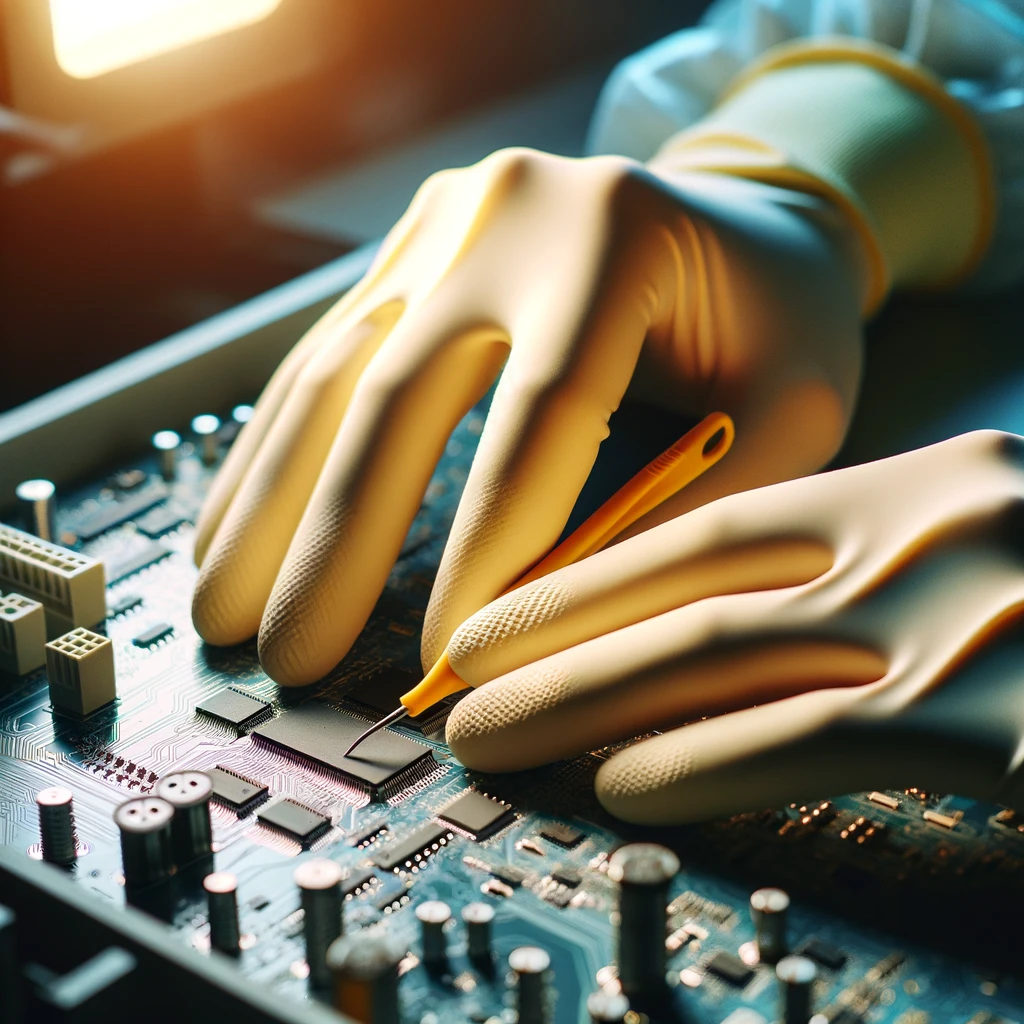

Precautions Before Cleaning Circuit Boards

Before cleaning circuit boards, it’s essential to take several precautions to ensure safety and prevent damage to the components:

- Power Off: Simply turn off or unplug the device. Take several precautions from power because of electric shock.

- Anti-Static Measures: Buzz will be controlled by the anti-static wrist strap that protects from static electricity-damaging components

- Ventilation: Ventilate your space well if you are going to be dealing with vapors from cleaning agents.

- Proper Tools: Implement the right means for cleaning, noting that compressed air, soft brushes, and isopropyl alcohol are required here.

- Avoid Water: Do not clean circuit boards with water by itself because it tends to cause rust, corrosion, and other damage to the components.

- Gentle Cleaning Solutions: –Apply light pressure to the surface of the printed circuit or its components while cleaning to avoid any damage.

- Drying Time: After the circuit board has been thoroughly being exposed to the air, reassemble it or reconnect it to the device.

The above measures will help you to save the life of your circuits and, of course, maintain the functionality of your electronic devices.

Why is Cleaning Circuit Boards Essential?

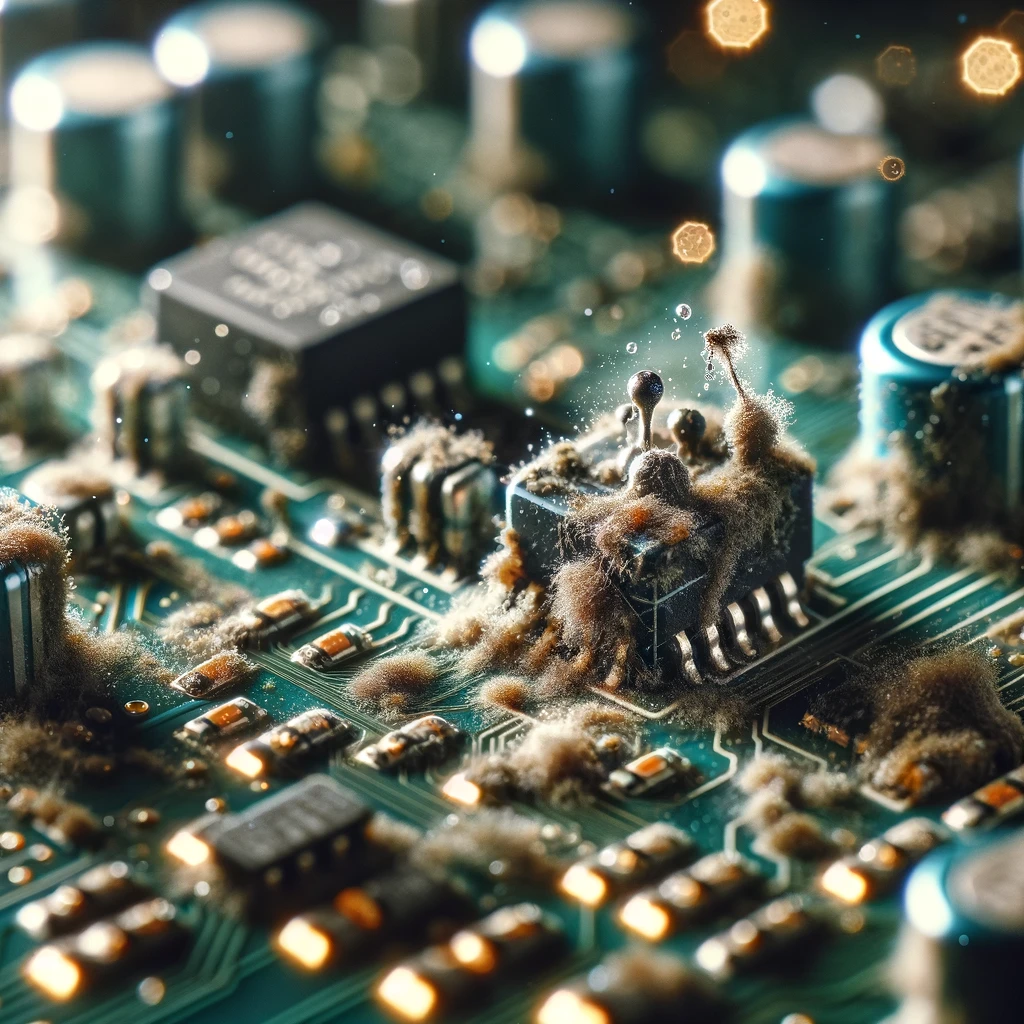

Cleaning of circuit boards is necessary for both the best functioning and the longest life of all electronic products. accumulation of dust, dirt, and debris on circuit boards as time goes by could result in many problems. Cleaning electronic circuit boards is a vital issue regarding correct functioning, trustworthiness, and the duration of operation of electronic applications. It excludes corrosion, provides reliable connectivity, curtails heat emission, and maximizes the function of the appliance.

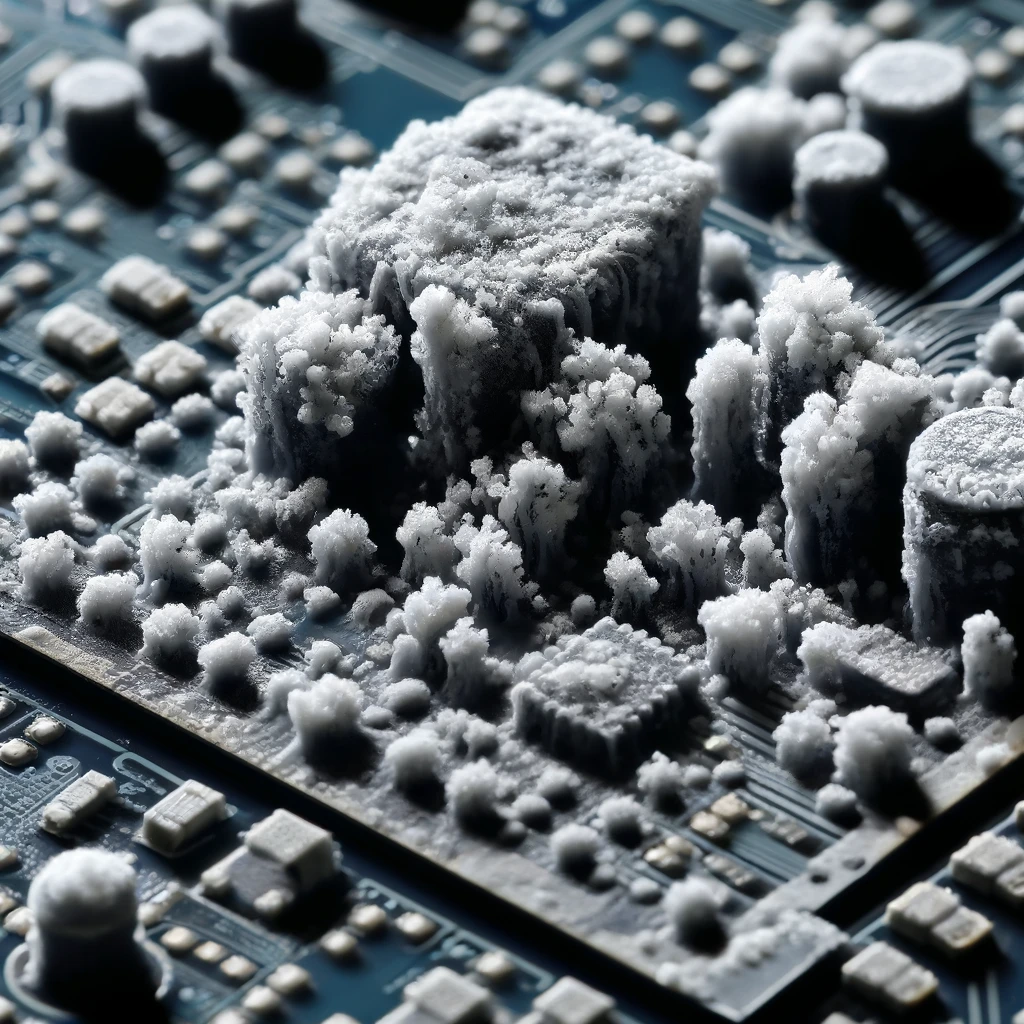

Preventing Corrosion

Dust, dirt, and debris may also be roped in that can contain corrosive elements, which could damage the circuit board eventually. Regulated cleaning gives protection from corrosion in the long run, thus keeping the board operational even for longer periods.

Maintaining Electrical Connectivity

A cloud of dust and dirt can settle on the signs and connections between circuit board components, resulting in a poor electric connection. Cleaning guarantees that electrical impulses flow through, and so it is free from problems.

Preventing Overheating and component failure

Cumulative dust and dirt can also be traced to overheating of components if they become too immune. The board cleans up so that it doesn’t only allow air to flow, but it also prevents hot component hazards.

Ensuring Reliable Performance

A clean circuit board is the one that is more likely to show good performance. Dust and dirt removal can be an excellent way to reduce issues connected with the short circuit, other problems with electricity, and eventually the damage to the device.

Improving Aesthetics

Such cleaning of the circuit board can also enhance the device’s general attractiveness. The surface of a clean circuit board is more attractive and it indicates a device which is in good condition.

When should I clean circuit boards?

It requires awareness of when to clean the circuit boards in order to attain top performance and protection from damage. Periodic maintenance is needed, as the accumulation of dust, dirt, and other debris can result in mechanical issues. Dirt or dust sitting on the circuit board is a very obvious sign that cleanliness is necessary. Regular use or operation in dusty areas might be subject to more frequent interruptions for it to be cleaned.

Efficiency can be affected in the opposite way, including overheating, intermittent communication, and device defects, which may also serve as signals that the gadget needs to be cleaned. Prophylactic cleaning done when it’s not obvious can ensure the overall functionality of the circuit board and, thus, prevent more serious issues from occurring. Nevertheless, you should clean up circuit boards on a routine schedule, and you have to stop the cleaning process if you find dirt or performance problems.

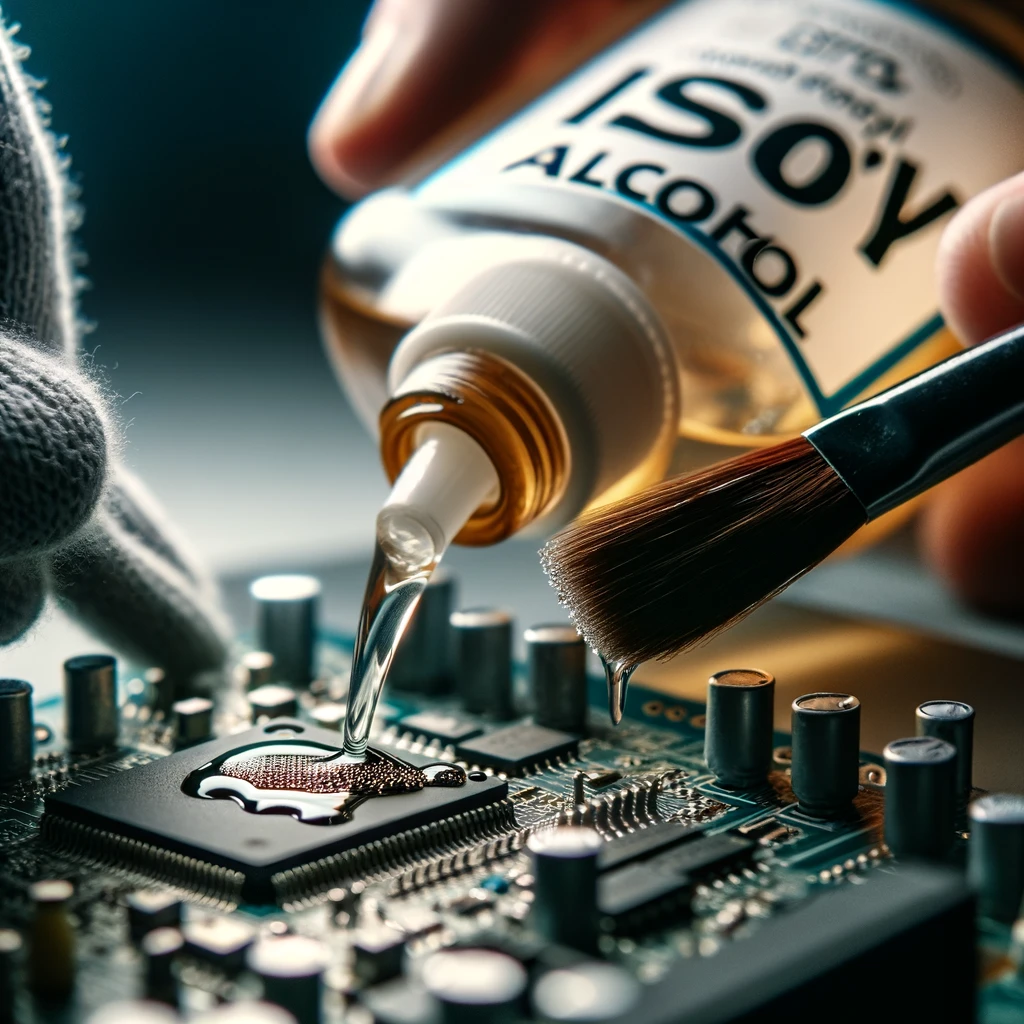

How do I clean circuit boards with isopropyl alcohol?

Using alcohol in the cleaning of circuit boards with the process of isopropyl alcohol is the usual approach. Here’s a step-by-step guide on how to do it safely:

- Preparation: Have all these ready: alcohol with 90% or higher purity, cotton swabs, a soft brush or brush, and canned air.

- Safety Precautions: Before proceeding, make sure the device has no power and also do not plug it in to prevent any electric shock. Put on an anti-static wrist strap to cover up static discharge.

- Dust Removal: Use compressed air for dust-and-debris removal from your circuit board. Stretch the can and don’t let the liquid out.

- Spot Cleaning: A cotton swab dipped in clean isopropyl alcohol can be very effective for removing the dirt and grease from stubborn stains. Be alert so that you do not drain the board with alcohol, because excess moisture can ruin the system.

- Scrubbing: If a detailed cleaning is required, briefly immerse a soft brush (for instance, a tooth brush) into isopropyl alcohol and lightly rub the circuit board to remove dirt and grease. Make use of light pressure so that you don’t break or damage the parts.

- Drying: If your circuit boards have accumulated a lot of dirt and grease, dip a soft brush (a tooth brush will do) in some isopropyl alcohol and brush the circuit boards to remove the dirt. Use a light pressure while taking apart the item and ensuring that the various parts are not broken or damaged.

- Inspection: Finally, check the pre-sanded board to see if it still has some dirt or fissures. Should the previous process apply, make sure to clean the post again.

By paying attention to all the details, such as proper surface temperature testing and the correct selection of alcohol concentration, you can clean your circuit boards safely and keep your devices in working condition by using isopropyl alcohol.

What is the cleaning solution for circuit boards?

It is important to mention the fact that there are a number of cleaning agents that can be applied to clean the circuit boards, according to the type of debris or contamination. Here are some common cleaning solutions:

- Isopropyl Alcohol:Isopropyl alcohol is probably one of the most popular and widely used solvents for PCB cleanings. It quickly reclaims and cleans surfaces very well while leaving no residue behind. For the best outcome, one can employ an IPA of extremely high purity—more than 90%.

- Distilled Water: Diluted water can be used to wipe down circuit boards along with other cleaning agents, or it can be used for rinsing the boards after applying solvents for cleaning. It is essential that distilled water be used instead of other kinds of drinking water to eliminate the formation of mineral deposits on the board.

- Electronics Cleaner: There are commercial PCB cleaners that are manufactured specially for cleaning chips. These cleaners contain substances that pose no threats to electronics and can be used safely for the removal of dirt and contamination.

- Contact Cleaner: The main purpose of contact cleaners is to clean electrical contacts so that they can be applied to boards to remove the most dirt and oxidation from connectors and switches.

- Flux Remover: There are flux removers. Flux removers are used to eliminate flux residues left over after lead-free soldering. They are frequently employed along with other cleaning detergents to ensure an immaculate result.

For proper cleaning of electronics, one should use safe solutions and refrain from using any other liquids but those recommended by the manufacturer. Apart from that, do not forget to conduct the test regarding the application of the cleaning solution in a small and unaffected spot of the circuit board before applying it to its whole surface.

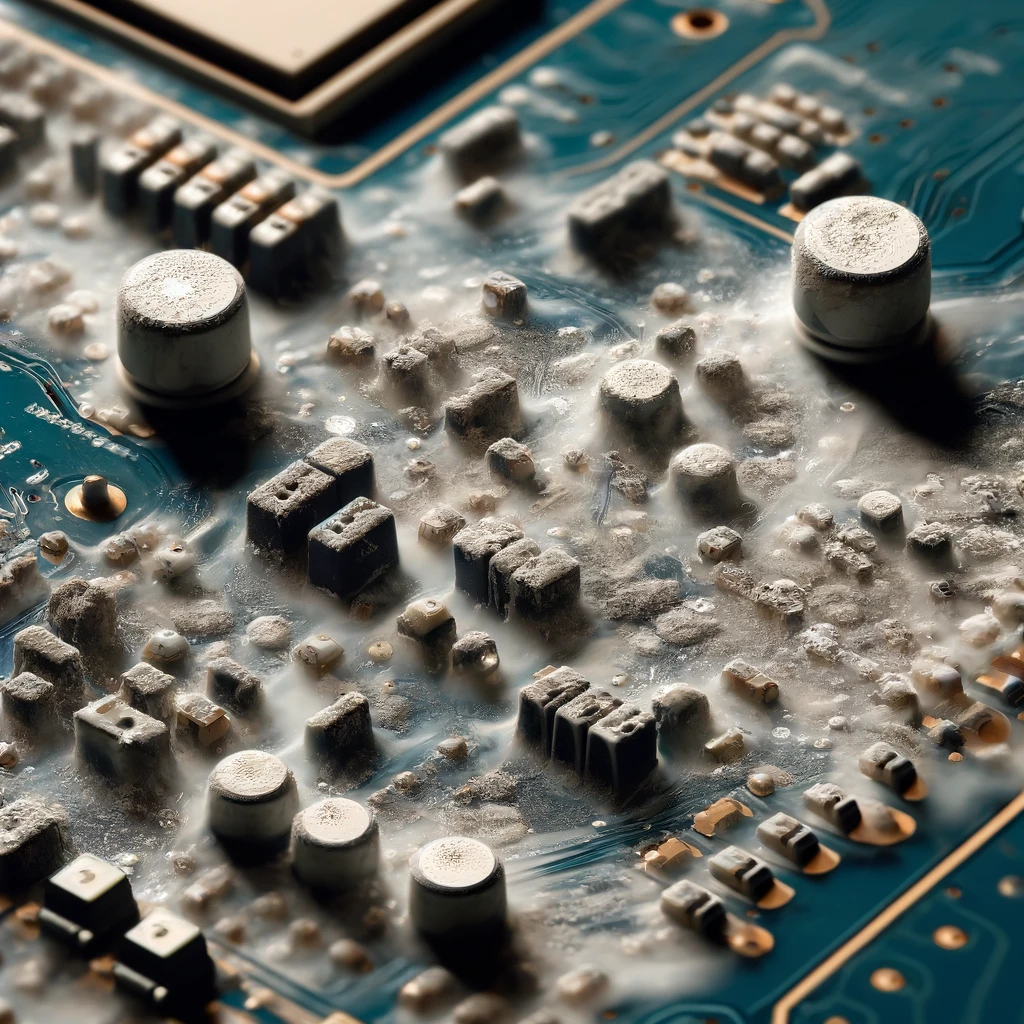

How do I clean circuit corrosion?

The cleaning of corrosion circuit board is considered as an obligatory measure to avoid additional harm and sustain performance. Here’s a step-by-step guide on how to clean circuit corrosion safely:

Safety Precautions

Before starting, make sure to have the device off or unplugged to avoid electrocution. Use anti-static wristband to prevent the buildup of static charge.

Assessment

Check the circuit board for corrosion signs, e.g., white or green rust. Find out the areas with loaded-up garbage that will need cleaning.

Isolation

If the chip can be safely removed from the device, it is advisable to detach the board to prevent other components from getting affected.

Cleaning Solution

Prepare a cleaning solution by mixing isopropyl alcohol (90% or higher purity) with distilled water in a 1:Our top-of-the-line CPUs feature a high core count ratio. This method proves to be one of the most efficient ones in the removal of corrosion and dirt.

Application

Apply a soft brush or cotton swab to the cleaning solution. Then, with a light scrubbing movement, treat the damaged areas on the circuit board. Please don’t apply excessive force to the surface, as this may cause it to crack or warp.

Rinsing

Scoop the rescued pot first, then rinse it with distilled water using a cotton swab without leaving any debris.

Drying

Let the circuit board dry in an airy place without touching it until it is completely dry, then assemble/reconnect it to the device. Using a hair dryer at a low, cool temperature is a good solution to dry your hair faster.

Inspection

After the board has dried, take a look at it to make sure any corrosion or any other damage is fully removed. If necessary, reiterate the task until the board is clean.

What are the tools needed for cleaning circuit boards?

Circuit PCB board cleaning is a job that calls for the use of certain tools for the safe and valid purpose of cleaning them. Here are the tools needed for cleaning circuit boards:

1. Compressed Air: Compressed air is cleaned, and if blown over the circuit board, it takes away the loose dirt and debris. It comes in cans with a nozzle, so you can apply it without great difficulty.

2. Isopropyl Alcohol: Ethanol (90% or higher purity) is also a common solvent for cleaning the circuit boards. It plays an important role in the process of cleaning the dirt, grease, and solder particles off the electronic boards.

3. Distilled Water: Distilled water that combines with other cleaning agents and acts as a rinse to eliminate cleaning residue from the circuit board.

4. Soft Brush: A soft-bristled tool such as a clean brush or tooth brush can be used to lightly scrub the circuit board and remove dirt and debris.

5. Cotton Swabs: Cotton swabs are good when it comes to applying cleaning solutions to some particular areas of a circuit board as well as for wiping out extra detritus.

6. Anti-Static Wrist Strap: A static-wrist strap is a safety tool that must be worn to avoid the danger of static electricity that can damage the sensitive parts of the circuit board.

7. Safety Glasses: The safety glasses ensure that your eyes remain safe in case of contact with any cleaning agents or particles while cleaning the circuit board.

8. Gloves: Gloves will prevent you and your hands from absorbing or touching chemicals and residues, which will help you maintain a healthy and clean working environment.

These tools at your disposal will help you clean a circuit board, assuring that the application of your electronic devices is not compromised.

What is ultrasonic cleaning?

Ultrasonic cleaning is a process by which devices covered by high-frequency sound waves clean objects. By creating microscopic bubbles in a cleaning solution, the sound waves do a shattering action when they come into contact with the object’s surface.

Tiny bubbles perform a piano cleaning action by sucking in dirt and contaminants. This is the method that is highly productive, soft on sensitive items, and brings to areas that are hardly accessed by standard methods.

What are the safety and prevention measures for circuit boards?

It is crucial to pay attention to safety and preventive measures when it comes to working with printed circuit boards in order to avoid damage to the components and the proper provision of personal protection. Here are some key safety tips: Here are some key safety tips:

- Power Off: Ensuring safety while handling these electronic devices, which generate electrical power, is a must if you don’t want an electric shock.

- Anti-Static Precautions: Attach a static strap to your wrist in order to prevent the buildup of static electricity that might inadvertently damage delicate parts.

- Avoid Water: Water, or more importantly, moisture, is the enemy; avoid using it in any manner for cleaning the circuit boards as it can cause corrosion. By using appropriate cleaners instead.

- Gentle Handling: Handle circuit boards carefully and avoid applying too much force, as this may cause some of the components to be damaged.

- Proper Tools: Put the proper things to work as the tools, for instance, cotton swabs, isopropyl alcohol, and soft brushes, in order to not harm the circuit board.

- Work in a Clean Environment: Pay attention to how you store your work space, keeping it clean and dust-free, which helps prevent soiling the circuit board.

- Proper Storage: While not in use, store circuit boards in a clean and dry environment to avoid damage. Storing circuit boards clean and dry is important when not in operation because it can prevent destruction.

- Follow Manufacturer Guidelines: Make sure to follow the manufacturer’s recommendations about handling and cleaning circuit boards so as not to cancel your warranty or damage the circuits.

Through implementing these regulations of treatment as well as preventive actions, you can send a message that you want to make boards with a long lifespan and free from damage.

What causes corrosion in circuit boards?

Corrosion in the handling circuit boards can be caused by several factors, including:

- Moisture: When exposed to moisture from different sources, for example, excess humidity or water drips, corrosion on the chips is inevitable. Chemical molecules within the metal will be oxidized and become corroded after a period of time, accompanied by a loss of strength of the components made from the metal due to the freeing of the metal ions.

- Contaminants: Dust, dirt, and other contaminations can deposit on the PCB cleaner and spread on the material, generally affecting the metal components and promoting corrosion. These contaminants can, in turn, hold on to moisture, which manifests in the advancement of the process of corrosion.

- Chemical Exposure: Contact with these damaging substances, like cleaning solvents or flux remnants, gives rise to the corrosion on the circuit boards. The top priority is to maintain the integrity of the metal surface by employing the appropriate cleaning agents and employing careful cleaning techniques, avoiding the use of corrosive chemicals.

- Environmental Factors: There are a lot of environmental influences in place, such as temperature extremes, pollution, and airborne chemicals, that may influence corroding delicate circuit boards.

- Poor Quality Materials: The sourcing and employment of the cheapest materials you can find for the construction of circuit boards tend to increase the chances of corrosion in the long term.

- Electrochemical Reactions: Electrochemical reactions between the different metals on the circuitry board themselves can contribute to this corrosion, which is typically worsened by the availability of moisture and contaminants.

To avoid corrosion on circuit boards, it’s very important to limit dust and humid ingredients in the board’s environment. It is also crucial that carefully chosen materials are used. Finally, storage in a dry and contaminant-free area is a must, along with daily cleaning and proper handling.

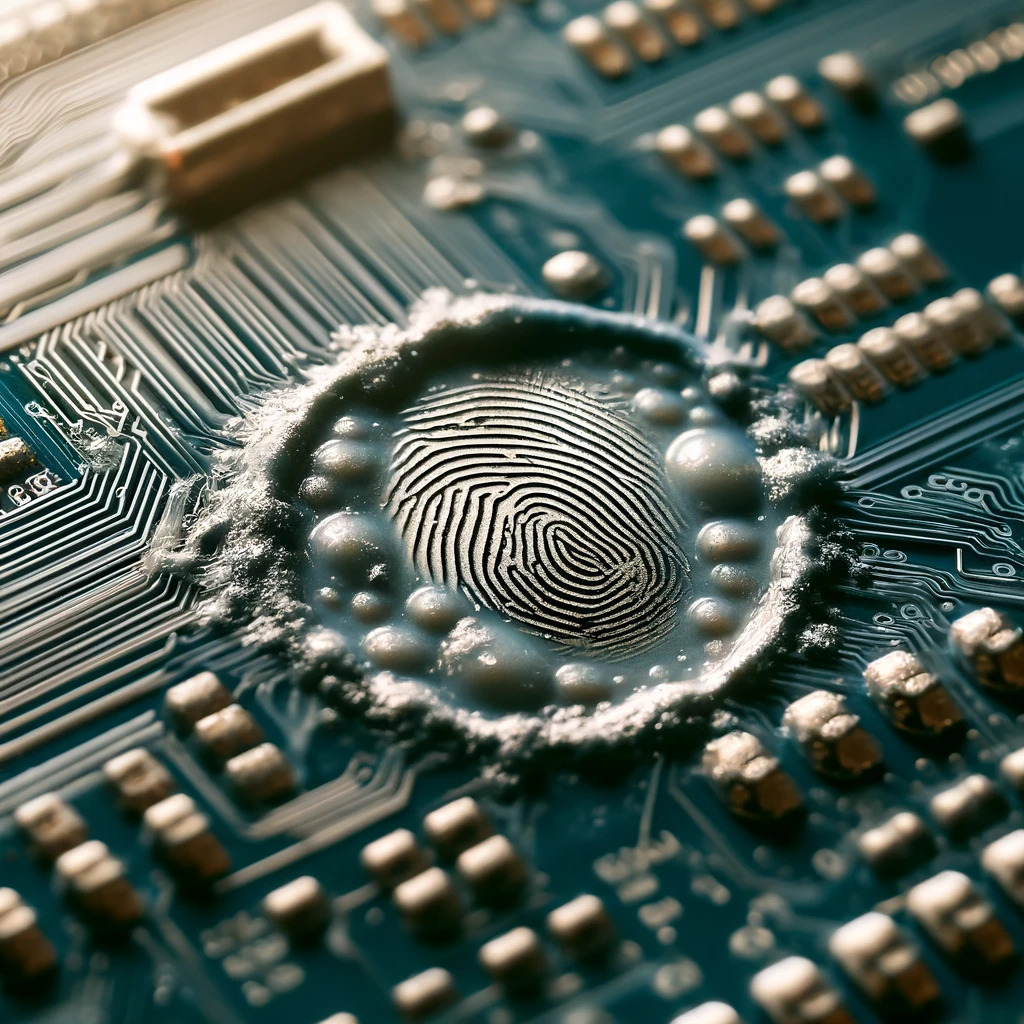

What is ionic contamination?

Ionic contamination is a phenomenon characterized by the presence of ionic substances like salts on the external surface or inside a material stack. In cleaning electronics, ionic contamination manifests in operating errors or breakdowns in electronic devices and disrupts their normal functioning by carrying electricity.

It is indeed a consideration during the course of manufacturing of the electronic boards and components, whose cause can be improper cleaning or mishandling. To prevent the complications of ionic impurities, a test and cleaning method for performance will be put in place for components to be tested before they are used in manufacture to meet the cleanliness specifications.

What Are the Most Common Ionic Contaminants From Bare Board Fabrication?

The most common ionic contaminants from bare board fabrication include:

Flux Residues

Ionic contamination in flux residues is the major cut source from the soldering processes in solder flux; some remove solder flux. Flux residues are made of certain ionic matter that tends to stay on the wood until it is properly cleaned, which is more challenging to clear and can cause flux dams in low stand-off parts.

Metallic Salts

Examples of metal-containing salts include chlorides, sulfates, and nitrates that are often involved in the manufacture of bare board materials. These salts can become puttable ions if they are not removed during the manufacturing process.

Dust and particles

Dust and particulates made by the environment can contain contaminations with ionic components. These types of pollutants can find their way into the bare boards while during the manufacturing process and contribute to the ionic contamination

Handling Residues

Oils left after touching boards, for instance, or contaminants that have leaked through gloves are all ionic substances that could make their way onto the boards.

Conclusion

At the end of the discussion, it should be clear that cleaning circuits is necessary for any chance of their working lifespan. Whichever you are dusting, cleaning dirt, or removing humidity, you need to follow the right cleaning methods or clean flux residues, like no clean flux. Initiate the operations by making sure safety regulations are applied, for instance, by putting the device in power-off mode and wearing the anti-static wrist strap. Utilize the correct cleaning tool and employ the right methods and cleaning solutions, like compressed air, isopropyl alcohol, and soft brushes, cleaning tools like ultrasonic cleaners for superior results; or phosphate-free household cleaner. Not using only water as it can affect water corrosion. aqueous fluxes, you can remove them by an inline cleaning method with distilled water. Besides, highly concentrated alcohol-based solvents can be applied to clear aqueous flux residues. Higher solids flux: Cleaning or (highly activated fluxes) a circuit board manufactured with a blend of different methods can also

Before you start assembling or connecting the board to your device, make sure it is completely dry of the pcb cleaning agents. Routine circuit board cleaning can be used to make sure that the function of the component will not be hindered or reduced.