While this method greatly accelerates the building process, it still requires skilled humans to put the pieces together, as robots currently lack the ability to remember certain things. Moreover, it can lead to wasteful practices that are not environmentally friendly; thus, technology ethics must be considered. The operating temperature range that will safeguard the integrity of the circuitry is another major factor that many engineers often overlook but is a crucial factor in the functionality of PCBs.

This factor is known as the glass transition temperature: (Tg). Knowing the definition of Tg, the reason why it matters , and its impact on PCB functionality is an essential knowledge requirement for all designers and manufacturers of electronic components. This article talks the issue up, which includes explicit presentation on why Tg is a fundamental parameter in PCB design and selection.

What is Glass Transition Temperature (Tg)?

Tg is also known as the glass transition temperature. This is the point where the PCB material changes from its rigid hard state to its soft and pliable state due to the transition of the glassy state to the rubbery state. which resistance (°C) is, is an essential material parameter for the temperature resistance. The epoxy or composite material, which is the base type, goes through such a transition here. The base material parameter for the temperature resistance is (degrees Celsius).It should be mentioned that Tg is not the melting point of the material but rather a phase transition that occurs where Tg begins to demonstrate different mechanical and thermal expansion characteristics.

Why is Tg Important?

This is the core added value of Tg in a PCB because it is the ultimate facility that directly imposes the load-bearing and heat-resisting properties of such a product. When the material is cooled down to a temperature equal to or lower than its Tg, it retains its stability under mechanical stresses and strains without changing its shape. Conversely, when the operating temperature intersects and exceeds the Tg, the material transitions into the rubbery state and becomes malleable, soft, and vulnerable to deformation when subjected to mechanical or thermal stress. As a result, such phenomena as delamination, warping, or a break in the conductive tracks may occur, which cause functional integrity failure.

Impact of Tg on PCB Performance

There is an impact of Tg on PCB performance when pcb’s operating temperature exceeds:

Thermal Management

The heat levels generated by electronic devices increase rapidly with the improvement of their parameters, such as size and power. Therefore, efficient thermal control is gaining considerable importance. The PCB maximum operating temperature with a high Tg is more worthy since the stability of the material at an elevated temperature implies high temperature resistance. In these high-current scenarios, like automotive, aerospace, or industry electronics, the thermal loads are high and therefore very critical.

Longevity and Reliability

In general, PCBs with a high tg material are harder to break or damaged under frequent expected operating temperature changes. Precisely, such dependability indispensable for devices that need to be operated over the edge, sometimes even in harsh conditions, with the aim of avoiding failures. For instance, the defense and aerospace sectors would normally require materials with especially impressively high Tg values for them to operate, notwithstanding the most extreme situations.

Manufacturing Process

The Tg of PCB materials is another parameter that influences production; it is the viscoelasticity of the materials, and the outcome of the curing process might be affected. The material that makes up the core and the solder paste all exceed their glass transition temperatures of less than 260 oC during the soldering process, leading to board warping or delamination. Hence, the selection of the material among the different materials with an outstandingly higher Tg than the soldering temperature that avoids manufacturing defects and, thereby, of course, a high-quality final product, is an absolute necessity.

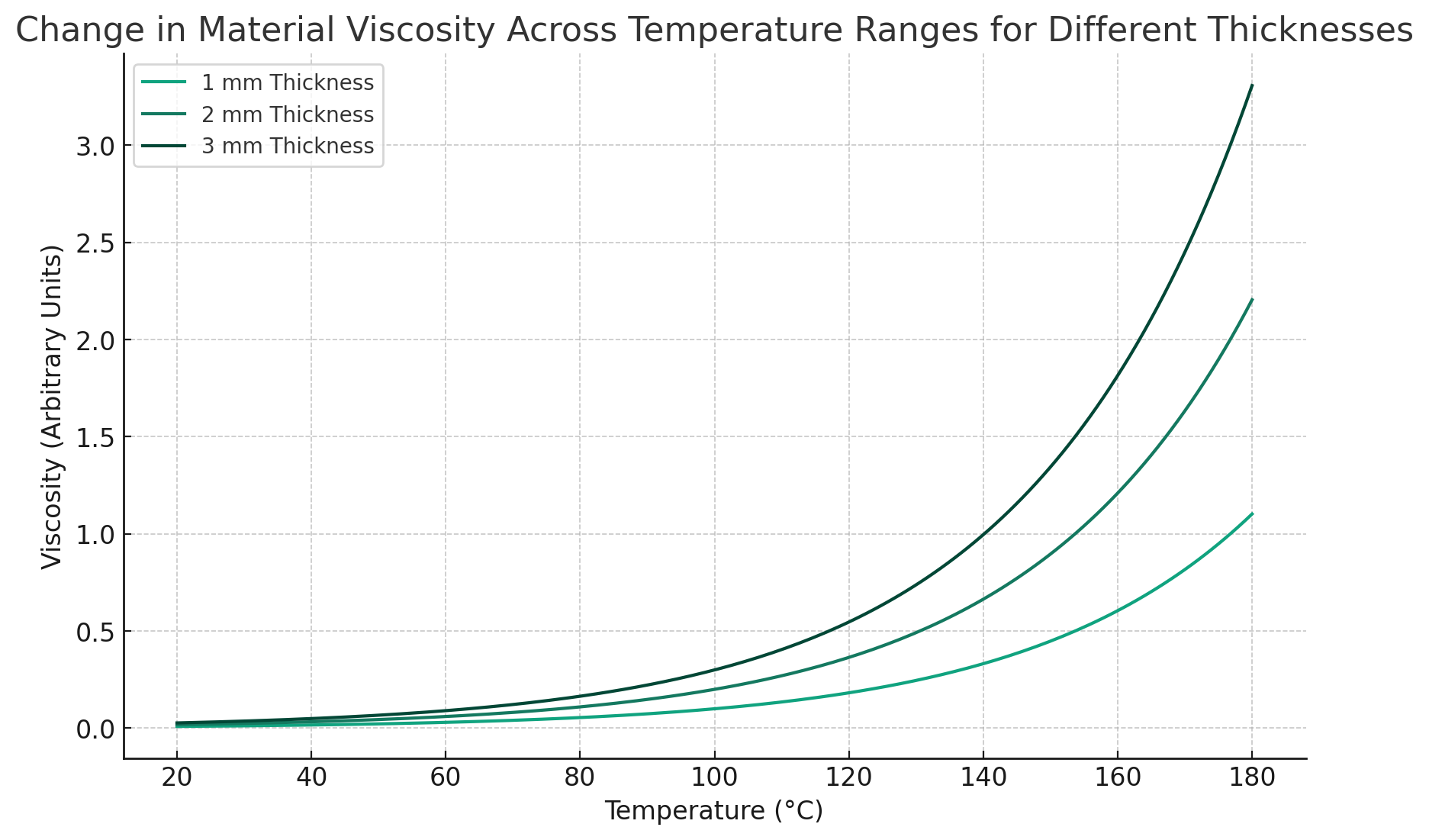

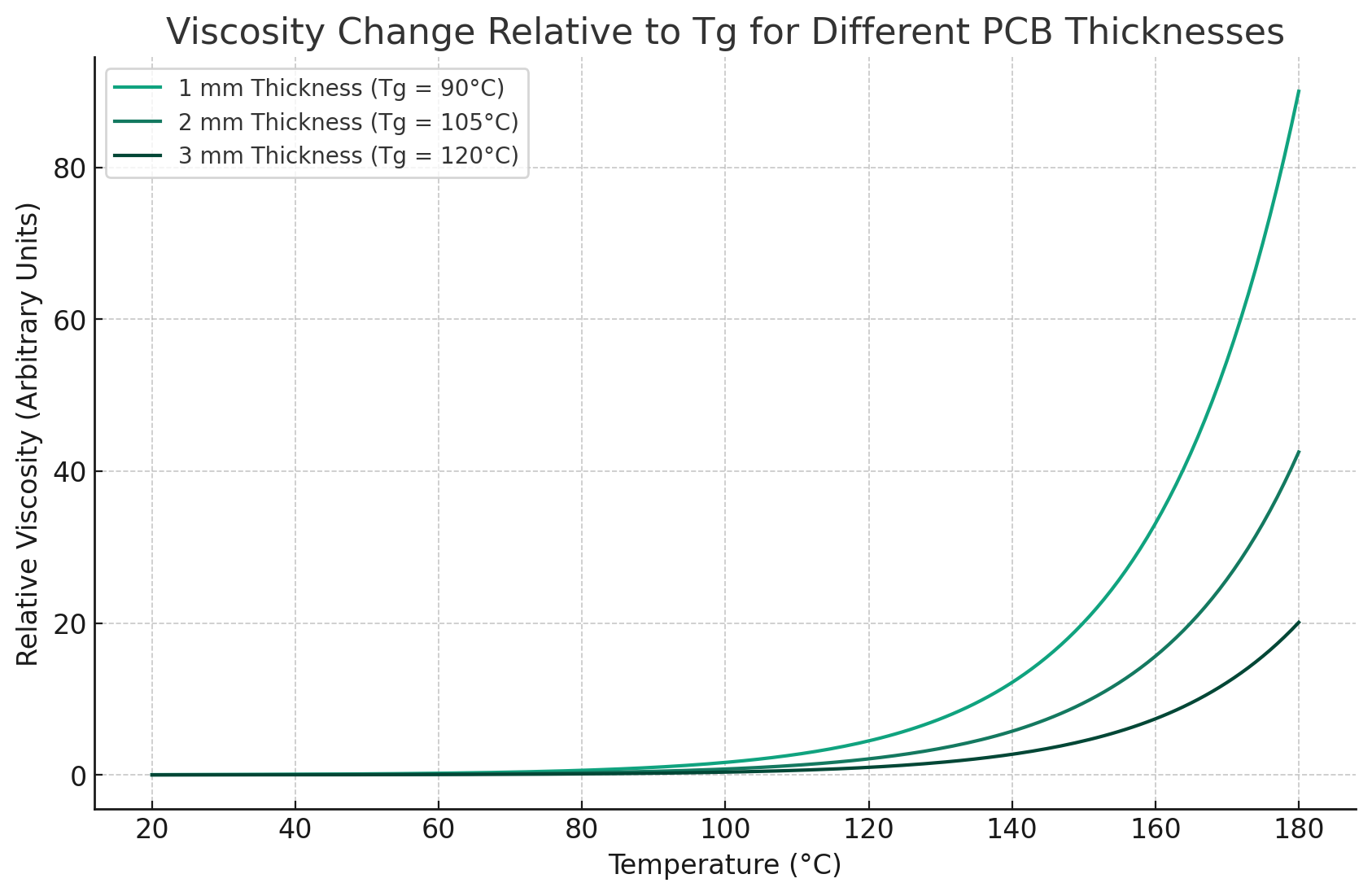

CHART for state change according to transition temperature range to thickness and temperature.

Materials’ viscosity increases when heated

The graph shows a decisive dependency of viscosity when the material (PCB) thickness is changing for the temperature range. Where a graph reveals an increase in maximum temperature, there is a commensurate rise in the material’s viscosity. The increased slope indicates a higher tendency to bend towards more fuller materials, as codified by the thicker curves in the graph. Through a heat dissipation map, it is easier to see how the components share the physical characteristics of the PCB material, which in turn ensures the performance of electronic devices under any working conditions.

To fairly predict the state evolution of materials that are temperature-dependent, the thickness changes, the heating impacts studied, and the viscosity that changes with heating, we can narrowly plot a chart. Such a mechanism involving high-TG boards of different thicknesses of film will be discussed accordingly. So, from this, we find that, assuming a conventional Tg value, a material goes from rigid to more flexible at these points as it approaches and exceeds the Tg points.

We have a chance to depict the liquidity point at which TV is dependent on the temperature for various thicknesses of conceivable PCB material, putting forth an opinion on the way liquidity flared out at various temperatures for different thicknesses.

The data presented in Fig. 3 shows the decrease in viscosity as the temperature gets closer to the glass transition temperature (Tg) for the various thicknesses of the PCB material. Each line represents a different thickness, with corresponding Tg values indicated:

- 1 mm Thickness (Tg = 90°C)

- 2 mm Thickness (Tg = 105°C)

- 3 mm Thickness (Tg = 120°C)

In this stack, below Tg (the glass transition temperature), the viscosity is substantial and gradually decreases as the temperature approaches Tg (the glass transition temperature). At this stage, the rest weakening effect gains momentum, corresponding to the material becoming softer and more elastic by passing the Tg. In this case, reliability in the electrical work is disrupted, as are those functions that might be affected by the current temperature. This simulation enables us to evaluate the material thickness to be used and to supervise their performance at operating temperatures, ensuring the expected device reliability and functionality.

When is it necessary to use a board with a high tg pcbs?

The operational temperature of the PCB has to be taken into account for the high Tg (glass transition temperature) printed circuit boards to be utilized, particularly in applications where the circuit board is anticipated to operate regularly in high-temperature conditions. Here are several situations where high-TG PCBs are typically required:

- High Power Density Applications: The PCBs that make a lot of heat, like power converters and fast processors, often need high-Tg PCBs in order to tolerate this kind of heat and not be degraded.

- Automotive Industry: In vehicles, extreme temperature changes are common, and road conditions are often challenging. High-Tg PCBs are put in places where the heat becomes more critical because of high engine temperatures, such as beneath the hood.

- Aerospace Applications: Just like motoring, high-temperature environments and other adverse aerospace conditions affect the environment when an engine is operating. For instance, in the aviation and aerospace industries, where equipment is subject to high temperature extremes, PCBs with high Tg are essential to ensure reliability.

- Industrial Electronics: Factories are highly dependent on the mechanical and electrical properties of their products, which are made to work continuously with high temperature and pressures applied. High-PCBs-Tg components are able to withstand external factors nicely in such environment.

- LED Lighting: LED light emission is highly temperature-sensitive. Hi-Tg PCBs are very essential to eliminate defects caused by high temperatures, like the ones that could be encountered at lamp fixtures.

- Telecommunications Equipment: These machines frequently are in constant-run mode and may be placed in environment like server rooms or outdoor areas that contain a high level of air temperatures.

Basically, high-Tg PCBs are specified for the components that will be dealing with high temperatures. Such a scenario would cause normal PCB to soften, deform, or even fail, thus jeopardizing the performance and safety of the electronic device.

Characteristics of High-TG PCB?

These high-temperature PCBs (printed circuit boards) can stand well at raised temperatures and maintain static properties without compromising structural quality. Here are some key characteristics of high-TG PCBs:

- Higher Temperature Resistance: The high-temperature PCBs are better than those of standard PCBs in terms of endurance, sustaining stability, and functionality as well.

- Improved Thermal Durability: These boards are immune to thermal fatigue, thus ensuring reliability and performance even in harsh circumstances where high temperatures are encountered.

- Better Mechanical Stability: All of these properties and advantages that are offered to HTg materials preclude their application under thermal stress and associated failure-modes like warping, delamination, or mechanical failure.

- Increased Chemical Resistance: PCBs with high Tg have high level of resistance to chemical and physical stresses, which are extreme in industrial and autotesting.

- Enhanced Safety: Their ability to sustain high temperatures reduces the possible failures and performance degradation that could potentially threaten safety, which is a core value of critical systems

- Longer Lifespan: A distinctive feature of high-Tg PCBs in terms of material properties is that they are durable in conditions with high temperatures and harsh environments, which leads to the long life of products where they are used.

High-TG materials used at Sierra Circuit table

Sierra Circuits, which is a company well known for its PCB manufacturing service providers, employs different high-TG materials to serve the purpose for which they are required. The applications where noticeably higher temperature resistance and reliability are the major operating parameters they focus on. Here’s a brief overview of some typical high-Tg materials used at Sierra Circuits:

FR-4: This is the most frequently chosen substance that has a Tg which is almost 180 °C and thus it is perfect for the majority of the popular electronic requirements.

Polyimide: The Tg for the polyimide is about 250 oC; thus, this polymer material is suitable for use in applications that entail extreme temperatures, such as aerospace and military electronics.

PTFE (Teflon): Frequently used in applications with high frequencies, such as microwave and radio frequency circuits, PTFE has a Tg characteristic value of 260°C, for example, providing superior thermal and electrical insulation.

CEM-3: Likewise, FR-1 ceramic material offers a comparable TG and is used as an economical substitute for FR-4 in critical applications as well.

High Tg FR-4: This kind of FR-4 is one of the most commonly used variants and has a Tg which is commonly more than 200°C. So it is suitable for high-power or high-density applications.

They are selected in accordance with their ability to stand high temperatures during operation without losing their structural integrity and performance. This crucial parameter has significant effect on operational and maintainable lifespan of PBCs under demanding conditions.

Choosing the Right Tg for Your Application

When selecting PCB materials, consider the following:

- Operating Environment: Evaluate the thermal and various mechanical conditions the PCB will endure. Because of the temperature is high, a high Tg is required.

- Application Requirements: Decide whether reliability and long range should be the first requirements. Medical and aerospace industries, where high reliability matters, would like highly tested materials.

- Cost Considerations: The Tg analogous high numbers demand for the more expensive materials. Create a ratio between the price and the advantages in terms or speed and robustness.

Conclusion

The right choice of Tg for your PCBs is key to Higher performance and reliability, as well as increasing the life span of your PCBs. With the development of the devices, the product having a moderate degree of hardness and having a relatively harsh environment is essential requirement, which is manifested by the fact that the Tg value gain more and more significance in the process of PCB design. When it comes to exact requirements of your application’s Tg, it’s crucial to choose materials that can support these characteristics. Featuring these precise requirements of devices results in optimal performance for the full lifespan expected.