Choosing the Right PCB Material: A Comprehensive Overview

The article provides an extensive guide on selecting the appropriate materials for printed circuit boards (PCBs). It explains the significance of PCB material choice for performance and reliability in electronic devices. The article describes various PCB materials like FR-4, high-frequency laminates, flex materials, and metal core PCBs, highlighting their specific applications and advantages. It also delves into other substrate materials like Polyimide, Teflon, Ceramic, Aluminum, and Nelco, focusing on their electrical performance, thermal characteristics, and flexibility. The piece further discusses different types of PCBs, including single-layer, double-layer, multilayer, rigid, flexible, and rigid-flex PCBs, along with factors to consider when choosing PCB materials like electrical and thermal properties, mechanical strength, chemical resistance, cost, availability, manufacturability, and application-specific requirements. The article serves as a detailed resource for understanding the various aspects and considerations involved in selecting the right PCB material for different electronic applications.

The Art and Science of PCB Manufacturing: Exploring the Process

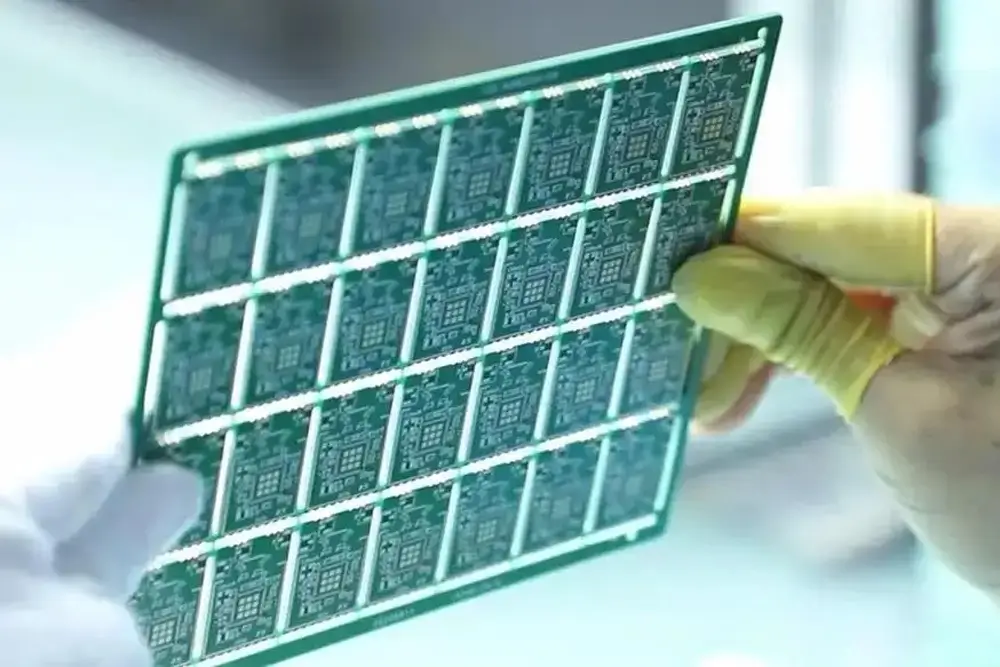

The article offers a comprehensive look into the intricate process of PCB manufacturing. It covers the detailed stages from PCB fabrication to assembly, highlighting the difference between these two critical phases. The fabrication process starts with designing the PCB layout using CAD software, followed by the actual board creation, which involves applying copper on the substrate and etching away unwanted portions. The assembly process then takes over, mounting components onto the board using techniques like SMT (Surface Mount Technology) and THT (Through-Hole Technology).

The article further delves into the various parts of a PCB, including substrate layers, copper foil layers, pads, traces, vias, and more. Each of these components plays a vital role in the functionality and performance of the final PCB product. The manufacturing steps discussed include designing the PCB, reviewing the design, printing the design, aligning layers, optical inspections, solder mask application, and finishing touches like silkscreen and surface finish applications. The article emphasizes the importance of precision and quality control throughout the PCB manufacturing process, ensuring the production of reliable, high-functioning printed circuit boards.