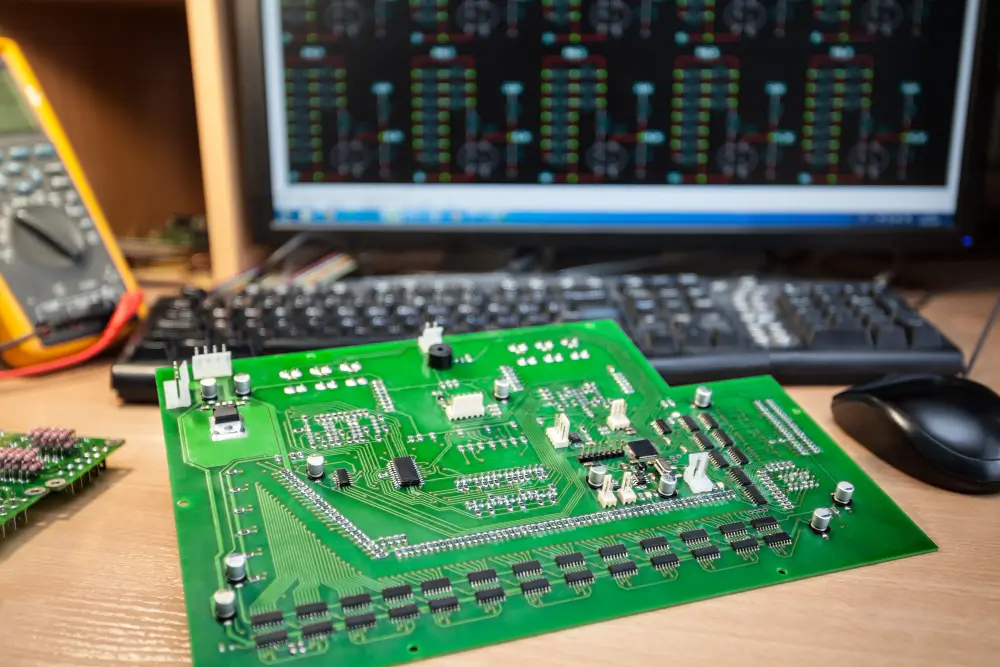

Designing of PCB: Unveiling the Secrets Behind Efficient Circuit Board Creation

Let’s venture into the world of PCB designs with the guidance provided in this in-depth article. Starting from design of analytical sheet to the assembly phase or bare board, the process of constructing high-efficiency printed circuit boards involves several techniques to pcb design rules, pcb design tool, pcb outline. Whether you are a newbie or […]

The Ultimate Guide to PCB Substrate Materials: Everything You Need to Know

Expand your knowledge of Printed Circuit Board (PCB) substrate materials with an exhaustive guide. Get acquainted with PCB substrate materials from fundamental aspects to advanced intricacies, which will be a great starting point and an in-depth review at the same time. Learn about the mean types of materials used in PCB manufacturing such as FR-4, […]

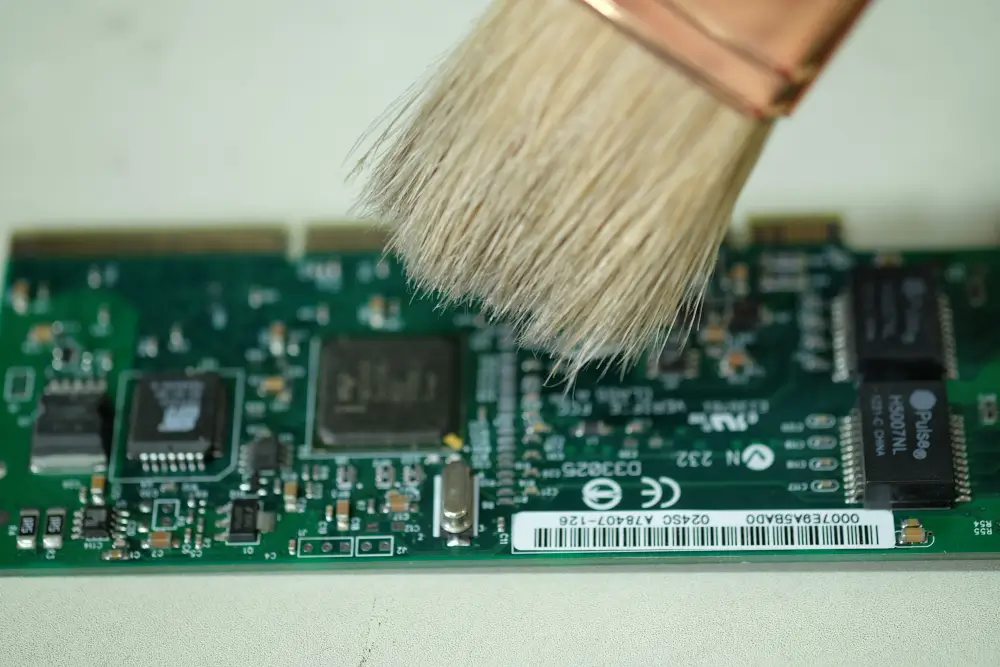

A Comprehensive Guide on How to Clean Circuit boards

Cleaning circuit boards is crucial for maintaining their functionality and longevity. Dust, dirt, and debris can accumulate on the surface of the boards, leading to electrical shorts or corrosion. This comprehensive guide provides step-by-step instructions on how to clean circuit boards effectively and safely. It covers various methods, such as using compressed air, alcohol-based solutions, and specialized cleaning tools. Additionally, it includes tips on preventing damage to the boards and ensuring they are thoroughly cleaned. Following this guide will help you keep your circuit boards in optimal condition, ensuring the smooth operation of your electronic devices.

Clean and Clear: How to Tackle Corrosion on Your Circuit Board Effectively

The document titled “Clean and Clear: “The Guide to Dealing with Corrosion on Printed Circuits” gives you a detailed explanation of how to manage corrosion on printed circuit boards. Here, the text explains the kinds of corrosion, like moisture, humidity, and chemical agents, and how they can affect the performance of the devices. The paper covers a range of corrosion types, such as even wear, galvanic, pitting, crevice, filiform, inter-granular, and stress corrosion cracking, describing how and on which areas of circuit boards these corrosion types appear.

A guide is presented showing the procedure of cleaning corrosion from PCBs in detail with special attention to safety rules, while some items like isopropyl alcohol, soft-bristled brushes, and lint-free cloths should be used. According to this, the use of paint that will not corrode, as well as carrying out regular services, are among the preventive measures.

Secondly, this document includes instructions and tips for identifying and diagnosing corrosion on circuit boards, teaching you how to identify the visual signs and the consequences of corrosion on the overall function of the device. It ends up recommending the importance of regular checks and servicing that help keep the corrosion process away and make the devices able to serve for a longer period of time.

Essential PCB Laminate Materials You Need to Know

PCB laminate materials are essential for the construction of printed circuit boards (PCBs), providing the foundation for electronic components and circuit traces. Some common PCB laminate materials include FR-4, a widely used flame-retardant epoxy fiberglass composite, and flexible laminates like polyimide, ideal for flexible circuits. High-frequency applications may use specialized materials like Rogers Corporation’s RO4000 series, known for their excellent dielectric properties. Understanding these materials is crucial for designing PCBs that meet performance, cost, and reliability requirements for various applications.

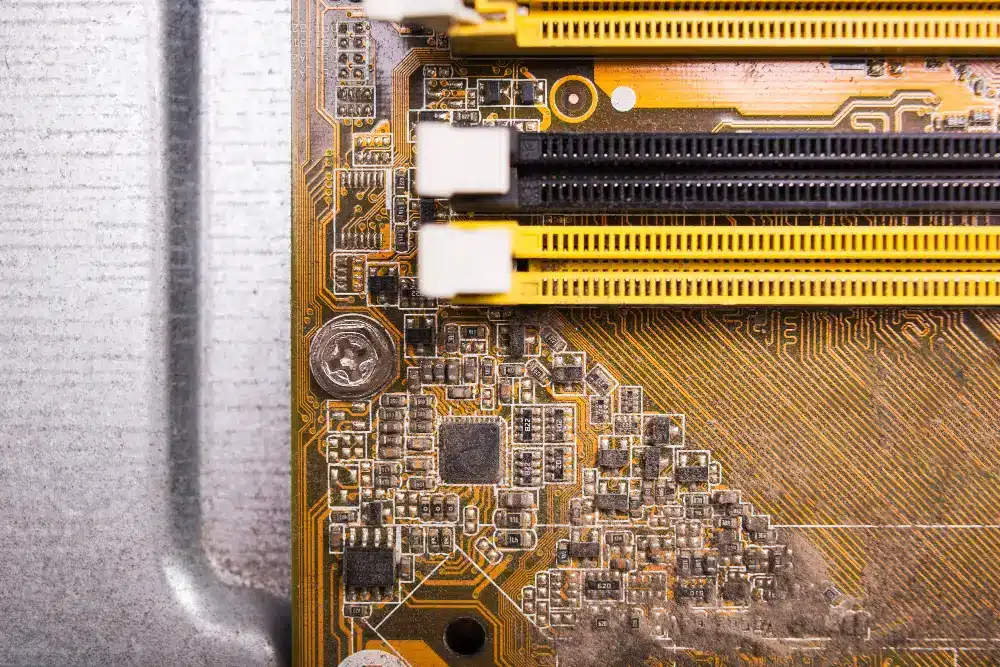

Everything You Need to Know About How Circuit Boards Work

On circuit board the tracks connect to form a network of electrical routes linking the components in a specific geometry. The component interaction from one to another and the way in which the flow of electrical pulses through the board are both defined by this design. What is circuit boards? Printed circuit boards (most often […]

The Ultimate Guide to Designing 2 Layer PCBs: Everything You Need to Know

Go under the hood of two-layer printed circuit boards (PCBs) and understand how they work with this detailed guide. From performance-critical design concepts to industrial pcb fabrication nuances, you will learn many ways to improve your 2 layer pcb, layout or layouts, address signal quality issues, grounding strategies and various thermal challenges. Acquire the essentials […]

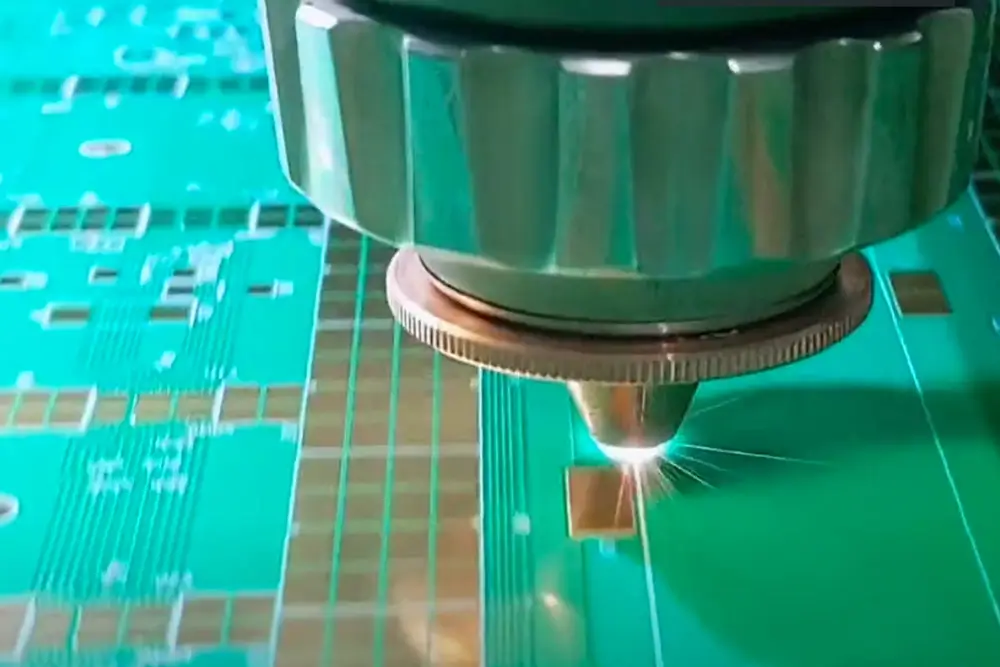

A Guide of how to cut PCB Boards: Tips and Techniques

Prototyping and PCB assembly in the field of electronics industry is made possible through a process known as cutting the PCBs from their original circuits. It’s critical that if you are sanderling a certain PCB board to match with the specified enclosure or doing patch in the case where partial boards are required to connect, […]

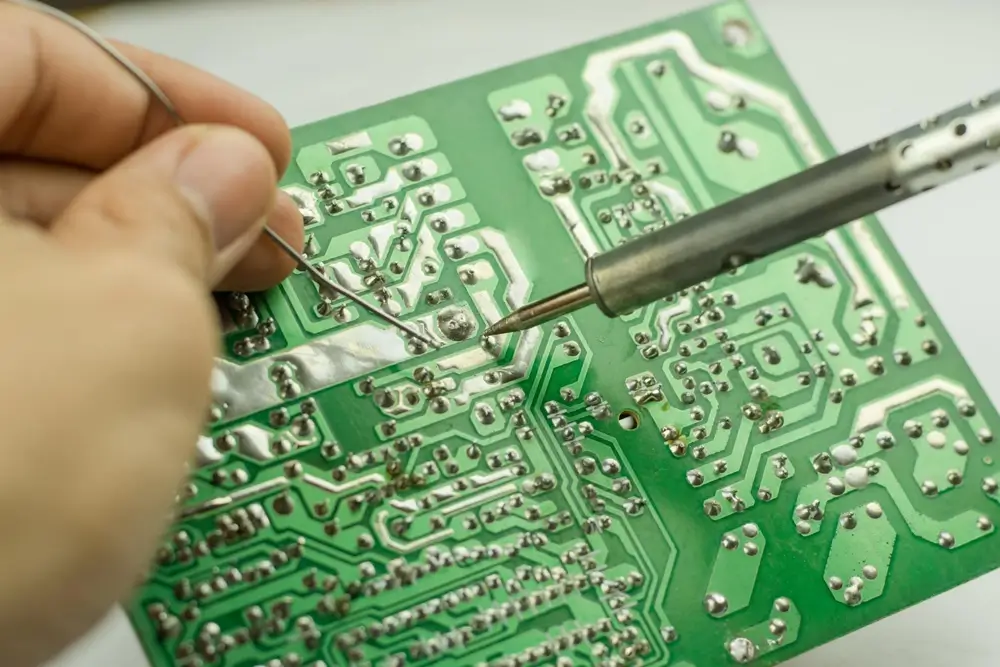

Key Differences Between Lead Solder vs Lead-Free Solder You Need to Know

The key differences between lead and lead-free solders—including their composition, environmental impact, and applications—are examined in the article “Key Differences Between Lead Solder vs. Lead-Free Solder You Need to Know” from Kingsignal PCB & PCBA Solutions. While lead solder’s lower melting point and affordability are highlighted, its potential health and environmental risks are also brought up. On the other hand, lead-free solder is harder to work with and has a greater melting point, but it is safer and more environmentally friendly. The essay makes the argument that performance, efficiency, and health factors should all be taken into account when choosing between the two.

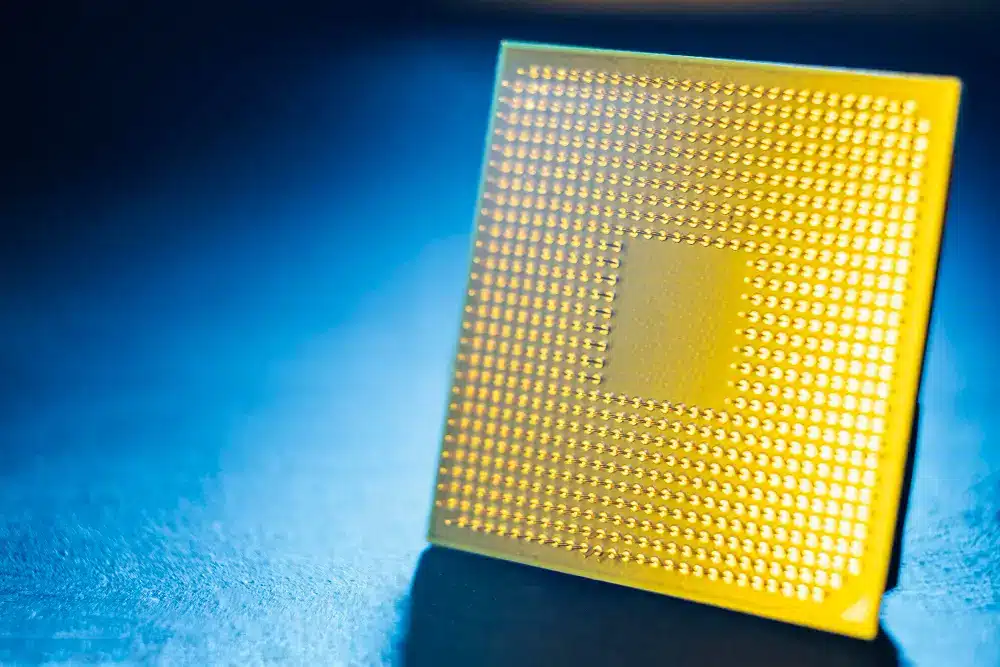

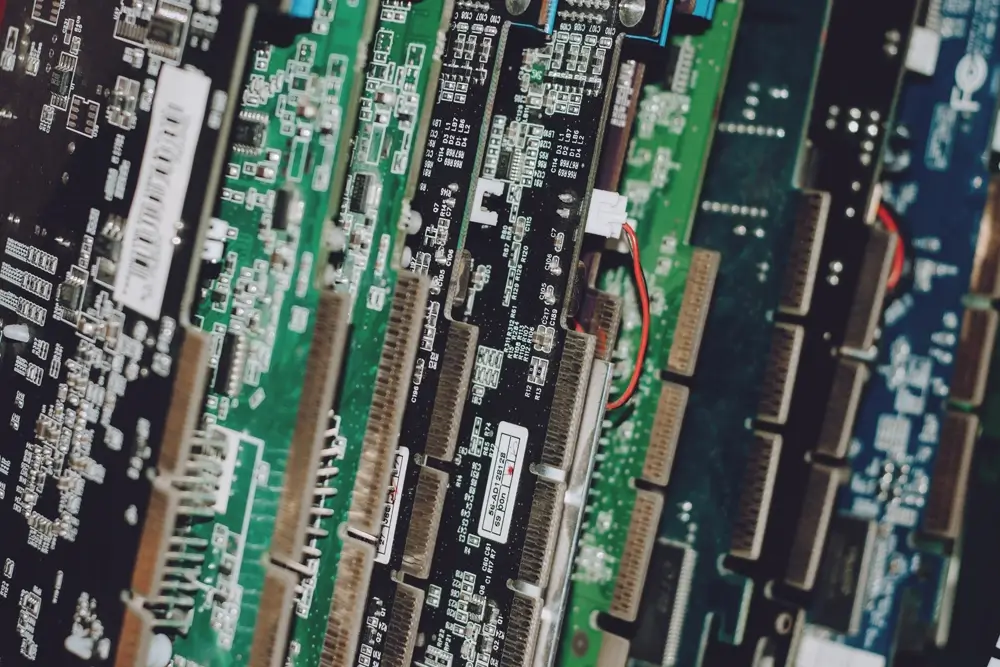

The Various Types of PCBs Unveiled

Printed Circuit Boards (PCBs) of different types are talked about in this piece. These include single-sided, double-sided, multilayer, rigid, flexible, rigid-flex, and high-frequency PCBs. It talks about their benefits and how they can be used in fields like medical devices, automotive, aerospace, telecommunications, green energy systems, and consumer electronics. It also talks about different PCB materials, such as FR-4, polyimide, aluminum, and ceramic. This thorough summary helps you understand the variety of PCBs and how to choose the right ones for your needs.