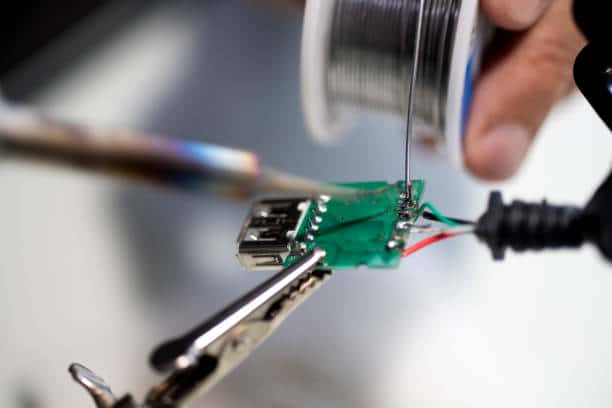

Let us analyze the key differences between lead solder and lead-free solder, taking into account their composition, environmental effect, and application in electronics fabrication. Determine which alternative best suits your needs. Leaded solder offers benefits such as a lower melting temperature, greater ability to flow and coat surfaces, lower costs, and a smoother shinier appearance, it poses toxicity and environmental hazards due to the lead content. Lead-free solder alternatives solve the problem of lead exposure but introduce new difficulties – a higher melting temperature makes it harder to work with, and poorer flow properties reduce reliability because it is less prone to evenly coat joined components and form strong metal-to-metal bonds. Choosing between these options involves weighing health, efficiency, and performance tradeoffs. Knowing the key differences in how they are made and their environmental effects will help you decide which type of solder to use.

What is lead and Lead free solders?

Lead – Lead solder is the term for soldering, which is the presence of lead as the main element and usually tin as a secondary component. Among reasons influencing the widespread utilization of this element by plumbing and electronics industries, the low melting point and ability to form extremely strong and highly durable bonds are the most important ones. On the contrary, however, lead is a hazardous substance and for this reason its use in consumer products is limited or made illegal altogether in many countries due to the health and environmental concerns.

Lead-free solder is a form of lead-free solder where lead is not used, which is exactly what this type of solder means. The variety of metals including tin, copper, silver, etc. are reacted in various combinations to form this creation of the lead free solder joints. the application of lead-free solder is now becoming more common in different fields like plumbing, electronics, and other areas where soldering is significant. Lead-free solder will offer a solution to the health and environmental concerns if lead solder will be used just like lead free solder formulations. On the other hand, it is sometimes harder to work with and it also requires higher melting points compared to lead soldering or lead free alloys.

Compare leaded versus Lead free solders

Lead solder, an lead alloys of lead and tin, has no toxicity or it is only somewhat toxic, and there are cases when it’s not allowed in some areas, and has a lower melting point, and always stays strong.

Compared to Lead free solders ; read it below

Lead-free solders that are made of tin, copper and silver are the alternatives. They have higher melting points, are weaker than the solders that use lead but are more ecofriendly. Hence, it is sustainable as well in the lead free solder wire. It can be overpriced for lead-free solder to exceed the price of lead-based solder, though it may be legal and even safer than wasting gas when idling.

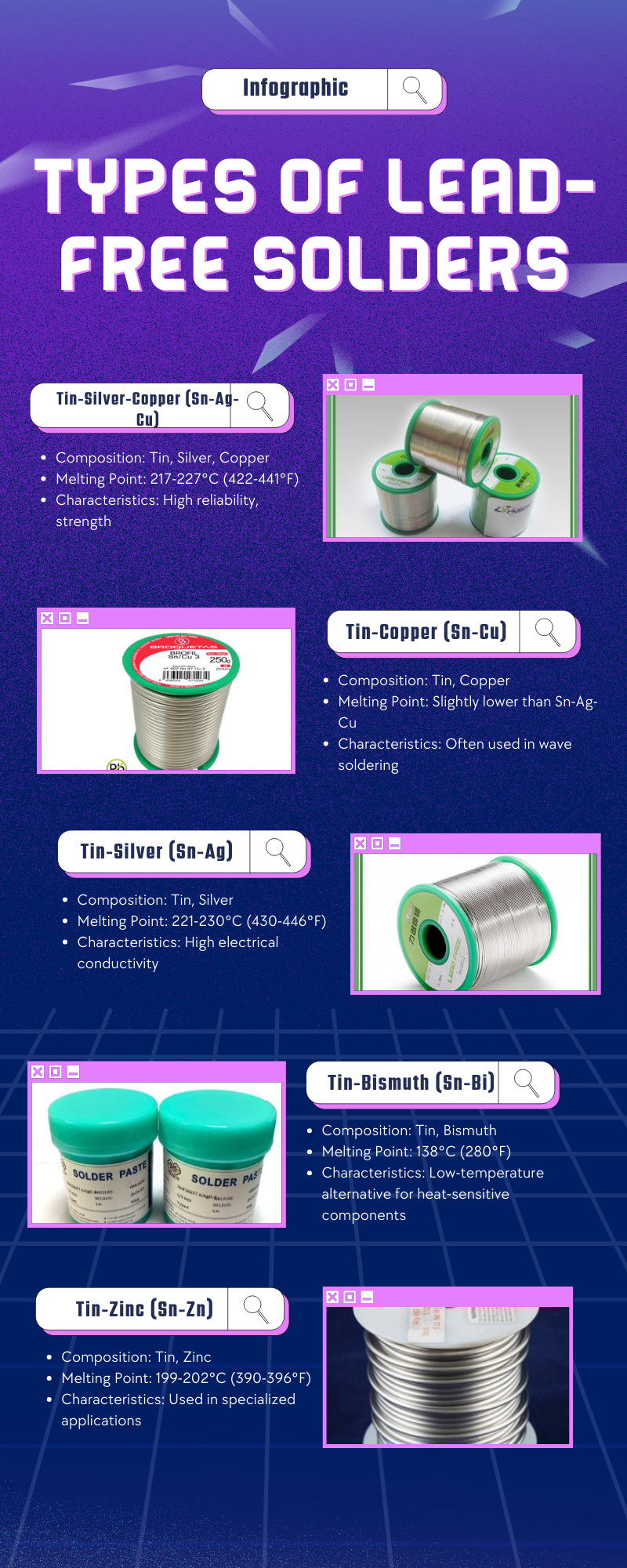

What are the types of Lead free solders?

Among the proliferation of lead-free solders, each of them consists of a different composition and properties that separate them to the more by embracing lead free soldering some with high lead emissions to the lead free products. Among the most frequent varieties are: Among the most frequent varieties are have a tin whiskers were those manufacturers replace tin just like tin alloy, tin metal, pure tin some have high melting point just read below :

1. Tin-Silver-Copper (Sn-Ag-Cu)

One of the most used solder alloys being lead-free is this one, with its remarkable reputation for the stability and strength. At the temperature it melts it is about 217-227°C (422-441°F).

Tin-Copper (Sn-Cu)

The type of solder is a eutectic solder that is commonly used in wave soldering. It is made up of tin and copper by implementation. While SnAgCu has a bit of a lower melting point when compared.

Tin-Silver (Sn-Ag)

This alloy is well known by its high electrical conductivity represented as an inter-mixing of tin and silver. It is the melting point between 221-230 degrees Celsius (430-446 degrees Fahrenheit).

Tin-Bismuth (Sn-Bi)

Is more and more a preferred option being a replacement of lead-based solders at low temperatures that are currently used in the industry. It features a melting point of approximately 138 degrees Celsius (280 degrees Fahrenheit), and it is usually applied in the sector of systems that have components which are heat sensitive.

Tin-Zinc (Sn-Zn)

Is a kind of flux that melts at a temperature around 199-202 °C (390-396 °F) and it is used in the specific customized applications.

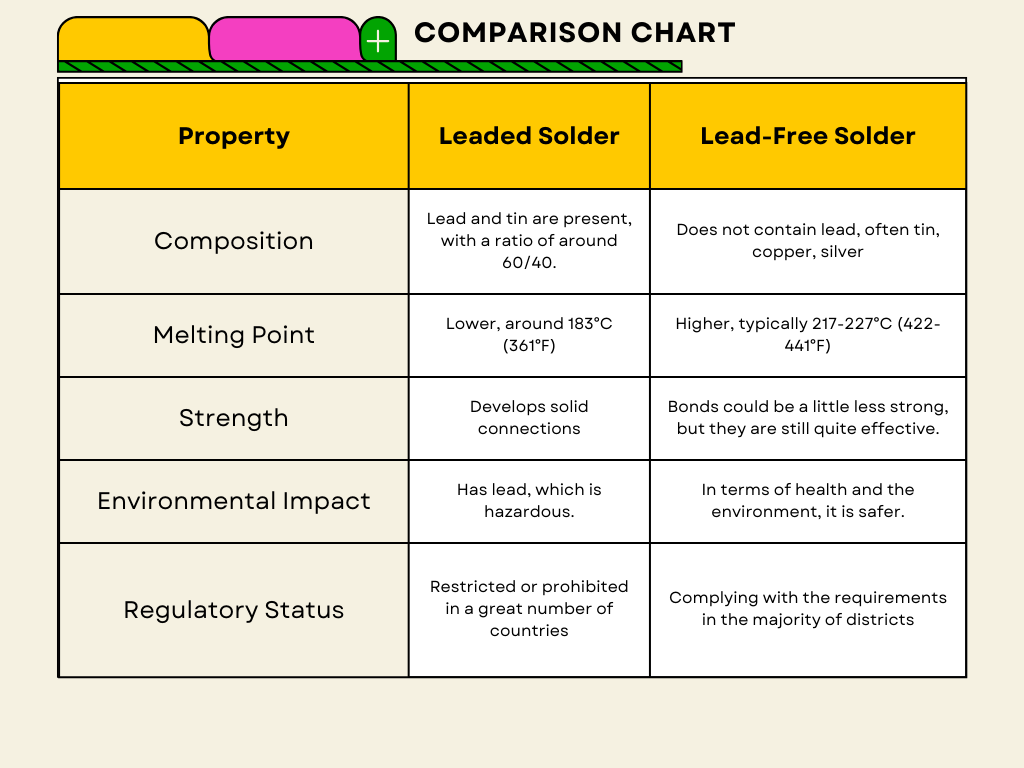

Five comparison of properties of lead and lead free solders

1.1 The table showed below:

Here is a table which provides a quick summary of main features of lead-based solders and of lead-free solders. The following qualities can be found in the different kinds of solder: composition, melting point, strength, environmental impact, as well as regulatory status which you can see each of their higher melting point which you can also decide to create tin whiskers or form tin whiskers.

Composition

- Leaded Solder: In a typical lead-tin solder alloy the lead (Pb) to tin (Sn) ratio is 60/40. Lead solder does contain both elements.

- Lead-Free Solder: In most cases, the solder is made of tin, copper, and silver, whereas lead-free solder does not have lead in composition.

Melting Point

- Leaded Solder: Usually, the melting point of lead solder is lower, hovering around 183 degrees Celsius (361 degrees Fahrenheit).

- Lead-Free Solder:Lead-free solder has a melting point of 217 to 227 degree Celsius, which is more than that of the traditional solder usually ranging from 180 to 190 degree Celsius.

Strength

- Leaded Solder: Lead solder helps to make bonds strong that are reliable.

- Lead-Free Solder: Solders which don’t contain lead may not be as tough as usual, but they are still excellent bonds.

Environmental Impact

- Leaded Solder: “Leaded solders” is a term which refers to the substance which is harmful for the health of a human and environment.

- Lead-Free Solder: more environmentally friendly and safer for people and not health threat as lead-based solder.

Regulations

- Leaded Solder: As lead solder exposes human health and the environment to risks, its application is resricted in many countries or totally prohibited in some others.

- Lead-Free Solder: The one which does not comprise lead is of the safest option and meets the standards set in most areas.

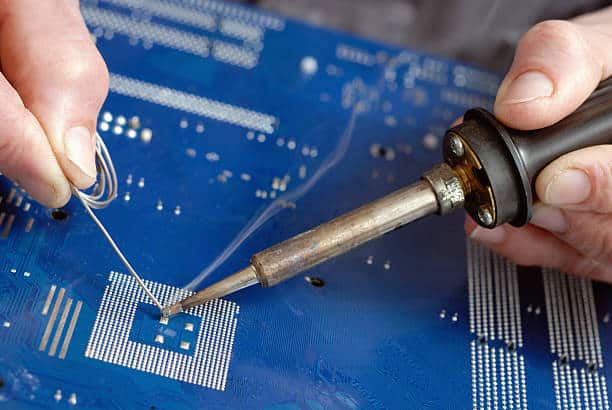

Switch to lead free solder

Switching to no-lead solder is a crucial step in line with environmental regulations and the elimination of health dangers of lead exposure.

On the contrary, it meets with the need of higher melting points while bonding that could be slightly less strong. On the bright side, it satisfies the modern legislation and standards.

Why Use Leaded Solder Still?

Even though leaded solder is not widely used due to the fact that other options offer lower melting points, improved flow properties, and joints which are more stable and durable, it is used in some applications because it comes with benefits such as low melting points, improved flow properties, and solders that have better forming and connection properties into the electrical and electronic equipment in the electronics industry.

However, this is changing in several different sectors as the lead-based solders are being replaced with lead-free solders due to concerns about the environment and people’s health especially those in electronic manufacturing which is also have sensitive electronic components.

Why Are People Using Lead Free Solder Then?

The decreasing popularity of lead solder is due to its harmful impact on the environment, which also includes the risk of lead poisoning which the government prohibits lead. A soldering process or the solder joints that eliminates lead and turns it into an alloy is less likely to be lethal to people and ecosystems through hole soldering with soldering iron.

The increasing popularity of lead-free solder is coming as countries around the world are passing their laws which limit or ban the utilization of lead in the production of consumer goods especially using lead free solder wire in the electronic manufacturing world.

What Is The Problem With Leaded Solder Then?

The most prominent drawback of leaded solder is its harmful impact on both the environment and human bodies. Lead is a chemical which is toxic and has the greatest risk of causing serious health problems especially in children and women who are pregnant. It is another reason why it may become damaging if it eventually penetrates soil and water and thus polluting various ecosystems electronic equipment directive.

To combat these issues, a number of countries have legislated for either a limitation or total prohibition of lead in solders use in consumer commodities. Thus, many enterprises have been turning to lead-free solders as a safer and more environmentally-friendly variant since current trend. This is despite the fact that the use of leaded solder offers us some benefits including cheaper price and stronger bonding as well as the fact that most of these benefits may not be worthwhile because the lead poses risks of harm to both human health and the environment.

What are the 5 Reasons People Still Use Leaded Solder?

Though it is known that leaded solders contain many hazards to both human health and the environment, people occasionally use it in particular situations for some reasons.

1. Cost effective

Due to cost size, the lead-based solder is a more affordable version compared to the lead-free equivalents, and that is why it is suitable for applications with the dimension of cost.

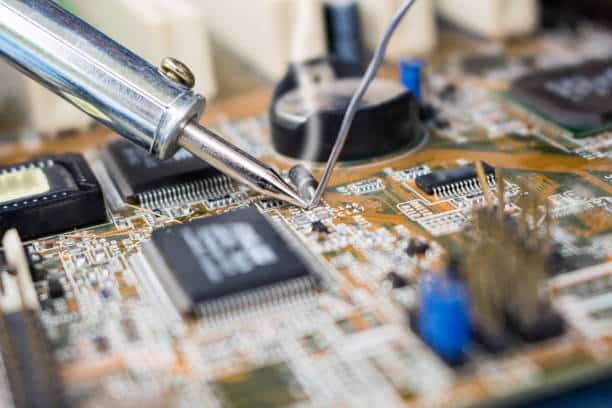

2. Ease of Use

The low melting point of lead solders is another highlight of the product that makes it easy to be used, especially in hand soldering applications. It’s easier to use lead solder because of its proven effectiveness.

3. Reliability

Leaded solder has a reputation of being very good at simultaneously producing joints that are both strong and reliable. This feature could be handy in cases of extreme necessity, when the same strength is required from the digits.

4. Availability

In some places the leaded solder availability is more common and is still well established due to the fact that the old process lines and the supply chains are already in place.

5. Regulatory Exemptions

The regulations might mention the cases of exclusions or concessions allowing the usage of solder having lead in some particular sectors or applications, but these apply only where the rules prohibit the application of solder with lead in the other ones. That is called the pathway of regulatory exemptions.

What are the pros and cons of Lead and Lead free solder

In order to determine whether kind of solder is superior, lead-based or lead-free, the unique needs and priorities of the application must be taken into consideration:In order to determine whether kind of solder is superior, lead-based or lead-free, the unique needs and priorities of the application must be taken into consideration:

Leaded solder

Advantages

- Leaded solder has lower melting point and it is therefore an easier component to use. This is one of the merits that come with this type of soldering.

- Client relationship which is becoming solid.

- It is commonly cheaper than lead-free solder in the majority of cases.

Disadvantages

- One of the negative features, which is the presence of harmful lead that can impact on human health as well as environment is the toxic lead.

- This limitation is included in several countries as it is prohibited or restricted.

Lead free solder

Advantages

- eliminates the danger for the environment because it does not have lead.

- Most of the areas’ needs are complied while still others find a way to stand out.

- Eliminates the risk of lead effects, which are delayed.

Disadvantages

- Another disadvantage is that it has a better melting point, which may require you to change the soldering machines and procedures.

- Given that wax might be a little weaker than those that solder leads, this is a possibility.

In the end, lead-free soldering is said to be more friendly to the environment as well as be healthier for humans. By doing this, it is the way out in many areas where the regulator compliance and environmental effects are the key factors to think over. Nevertheless, there is some equipment, where bullet solder is fine some have low dielectric components or have a significant component stress tot he printed circuit boards. Apartment installations, where the low cost and firmness of the solder is more important than the damage to the environment and health, belong to such applications in printed circuit board or in the short circuits.

Which one is better lead or lead free solder?

It is believed that lead-free solder is better as it has less impact on the environment and is less adverse to human well-being since it has lower probability of adversity linked to the lead exposure. In the long run, lead-free soldering compensation gives a much wider range of benefits than these factors, mainly regulatory compliance and environmental responsibility.

There are important differences between lead solder and lead-free solder. Lead solder and lead-free solder are made of different materials. Lead solder contains lead while lead-free solder does not contain lead. Both solders are used to join metal parts in electronics. Lead solder and lead-free solder affect the environment differently too. Lead from lead solder can pollute the environment. Lead-free solder does not pollute the environment like lead solder. It is important to understand how lead solder and lead-free solder are made and how they impact the environment so you can choose the best solder for your needs. Knowing the key differences in how they are made and their environmental effects will help you decide which type of solder to use.

Although leaded solder might be competitive in terms of cost and practicality of application, these benefits cannot be taken into account since the positive consequences of lead-free soldering are much higher. Leaded solder offers benefits such as a lower melting temperature, greater ability to flow and coat surfaces, lower costs, and a smoother shinier appearance, it poses toxicity and environmental hazards due to the lead content. Lead-free solder alternatives solve the problem of lead exposure but introduce new difficulties – a higher melting temperature makes it harder to work with, and poorer flow properties reduce reliability because it is less prone to evenly coat joined components and form strong metal-to-metal bonds. Choosing between these options involves weighing health, efficiency, and performance tradeoffs. Knowing the key differences in how they are made and their environmental effects will help you decide which type of solder to use.