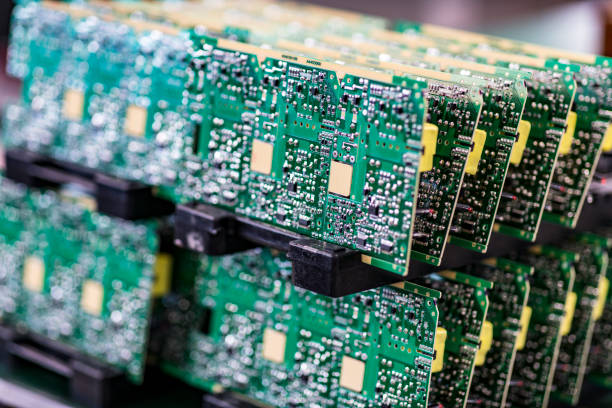

In the field of modern electronics, where seconds mean the world, time is of prime importance. Regardless of whether or not the PCBs belong to the engineer portfolio or hobby collection, having them in the most advanced state provide speed of realization (in less than a second) is of prime importance. This is why the aptitude of fast track PCB design comes into play. This guide is going to discuss in detail the quick prototyping methods and production so that the readers can gain the competency to cut down on their PCB development process time.

Understanding PCB Quick Turn

PCB Quick Turn is the principle of getting a printed circuit board (PCB) prototype and manufacturing it into the market in a shorter than usual time. To sum up, we can say that these are processes that give customers the opportunity to speed up production until vital quality characteristics are not damaged. Specific turn-around services have the ability to compress the time needed for the manufacturing process at the expense of time, and thereby, engineers can innovate prototypes rapidly and bring products to market ahead of time.

What are the types of printed circuit board quick-turn pcb assemblies?

PCB quick-turn services generally have no standard prices and a range of options that can be selected by the customer based on the specific requirement and deadline. Some common types of PCB quick-turn services include:

Standard Quick Turn: This is the most grounded mode of quick turn pcb manufacturing as it fastens the common delivery timeline for standard two- or four-layer boards with standard specifications and standard materials.

Advanced Technology Quick Turn: For sophisticated projects that require corresponding advanced features such as numerous layers, dense components, impedance control, or HDI (High-Density Interconnect) technology, quick turn services with advanced competence in producing complex PCB boards within tight lead times are the experts.

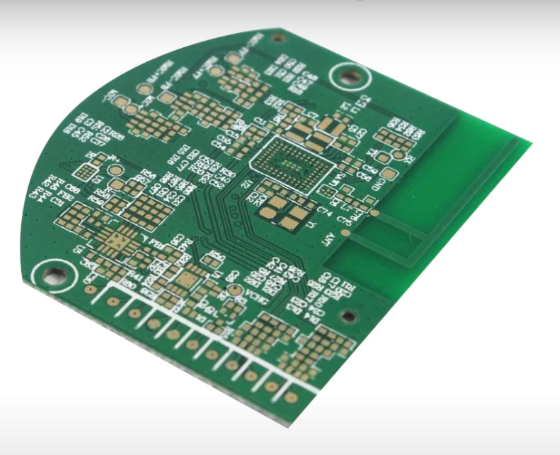

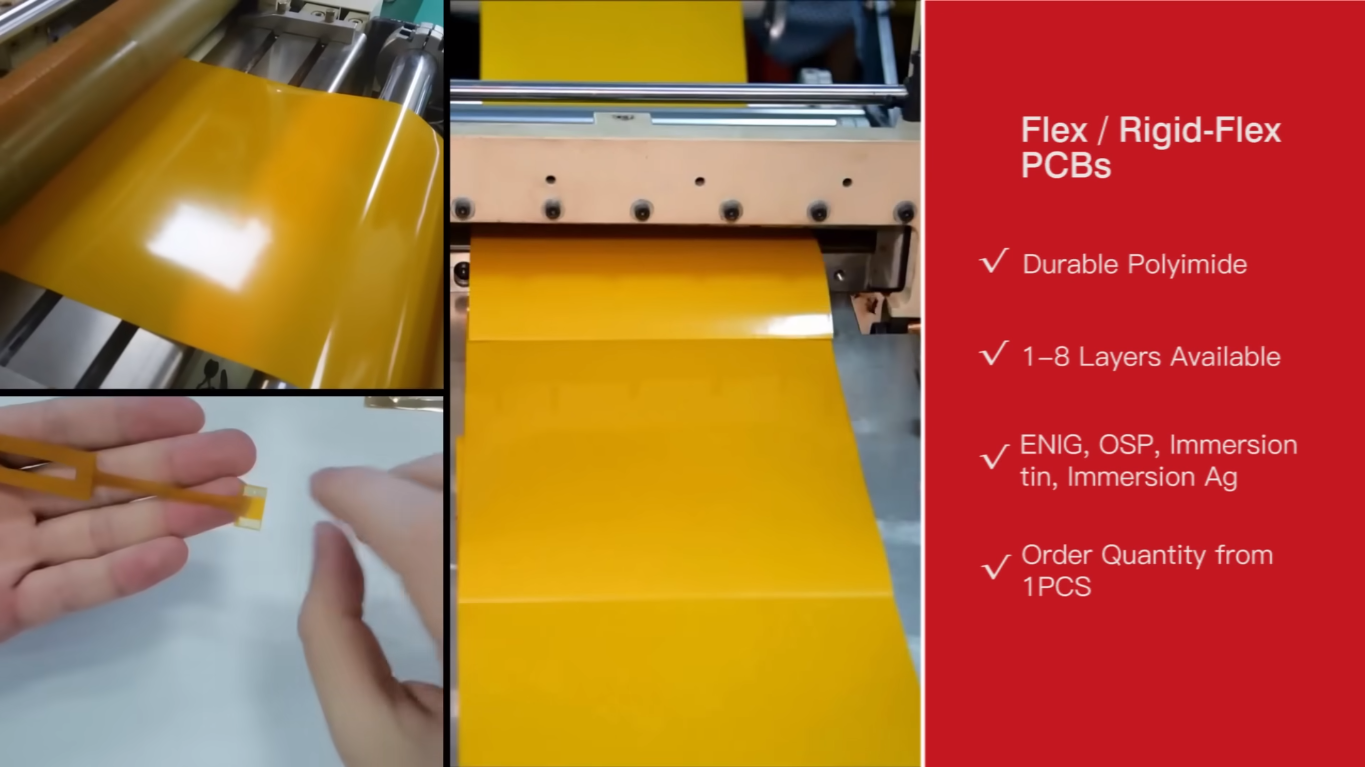

Flex and Rigid-Flex Quick Turn: Such services are based mostly on manufacturing flexible palm boards (PCBs) that are considered to be in great demand for projects involving compact designs or those of bendable electronics to rigid flex pcb. Fast setup plans speed up prototyping for higher-demand boards.

Prototype Quick Turn: Particularly designed for short production runs, these services strive to offer quick turnaround for limited quantities of printed circuit boards with the prototype. Often, shortcuts to achieve expedited manufacturing and assembly are applied to speed up the certification and release of new designs.

Assembly Quick Turn: Aside from PCB fabrication, rapid assembly of PCBs is likewise offered by quick turn services, and in this process, components are soldered onto the boards to complete the assembly that can lead to functioning prototypes or initial runs of production. This solution will be very convenient when there are some time constraints and you need a swift, fully functional PCB assembly.

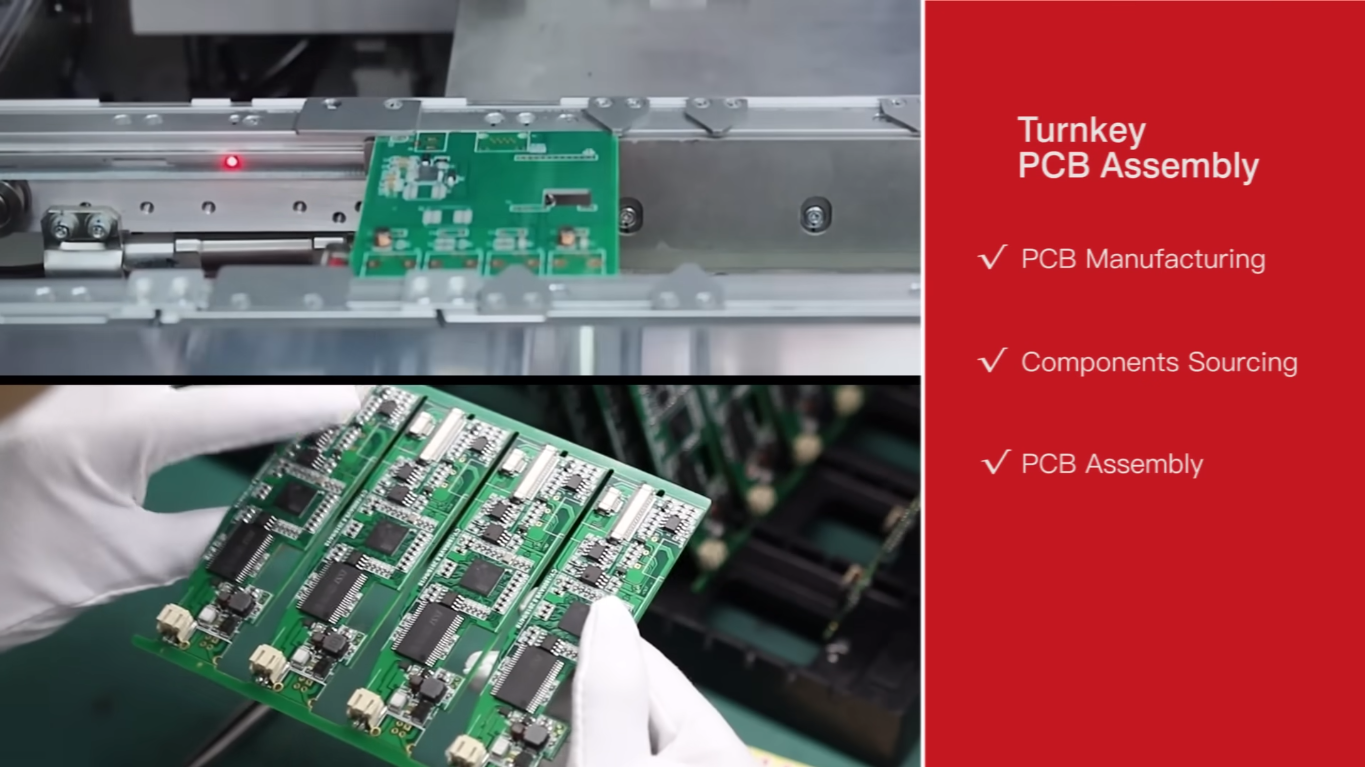

Turnkey Quick Turn: A Turnkey Quick Turn service offers a complete solution where the service provider holistically covers all the areas involved in the PCB manufacturing procedure, namely design review, component provision, fabrication, assembly, and testing. This sort of non-invasive practice makes things happen very fast and easily for the customer, with the finished PCBs just doing their task.

What is considered quick-turn pcb assembly manufacturing?

The little-time production PCB assembly means that the entire process of fabrication of the printed circuit boards (PCBs) into useful electronic gadgets takes the shortest time possible. However, the definition of “quick turn” can be based on the specific circumstances and purpose you are working for. Therefore, quick-turn services usually take less time than standard assembly processes, unless you are doing something more sophisticated than usual. Here are some common characteristics of quick-turn PCB assembly manufacturing:

- Accelerated Lead Times: Many quick-turn PCB assembly service providers usually advertise the shortened contract lengths that often range from less than a week to up to a couple of weeks, which depends on the nature of the project and the manufacturer’s ability to deliver.

- Rapid Prototyping: Fast turn rounds emphasize quick prototyping that enables engineers to effectively validate the design and, where needed, make the required modifications before the final version is done.

- Flexible Volume Options: While fast-turn PCB assembly is regularly maintained with low-volume production runs, there are some source providers that even give grace flexibility to all order sizes, starting from prototypes to small batch orders up to large production runs.

- Streamlined Processes: The lead time of concrete manufacturing factories for small-scale assembly services has been designed to fit time-saving and quality-assuring organization standards. For instance, it could include an optimized workflow, the efficient use of production materials, and automated technologies in assembly.

- Responsive Communication: The quick turn providers mostly communicate with their clients through various means to enable fast attendance to questions or any other problems, ensuring that the project runs smoothly and that the scheduled time is attained.

- Quality Assurance: Reputable fast-turn assembly services sometimes take quicker turns in developing procedures to guarantee the quality assurance measure and the finished product are as per standard and sometimes even exceed industry standards. There required for the implementation of the quality control protocols may be the compulsive tests, checks, and inspections.

Quick-Turn PCB Prototypes

Accelerated PCB prototypes: fast PCB prototyping is the immediate version of printing circuit boards, which bypasses all other steps for testing and validation of electronics designs.

Engineers are now able to use the quick turnaround times to go through the design cycles quickly, release their product to the market faster, and make sure that all testing is done properly and in time before putting the product into mass production. These prototypes provide flexibility, concern over product quality, and, importantly, reduce the likelihood of famishments during innovation and market entry.

Quick-Turn PCB Assembly

The term ‘quick-turn PCB assembly’ means that for a shorter time than a regular PCB (printed circuit board) takes to be assembled, the new PCB is produced with a fast turnaround time. This service eliminates the need for manufacturers to set up their own SMT lines as it simplifies the assembly of electronics into printed circuit boards, thereby reducing the time taken to prototype, test, and produce electronic devices.

The quick-turn PCB assembly service, with its consolidated production and assembly processes, makes available manufacturing and assembly to match the urgency of tight deadlines. Besides that, it enables fast prototypes of designs with state of the art production capabilities. These services are crucial for projects whose development cycles are fast-tracked and the barriers to go-to-market for their products are challenged with a shorter duration.

The Benefits of Quick Turn PCBs

- Faster Prototyping: Fast design iterations help engineers validate their concepts faster, reducing the time required to release the product that is already working.

- Flexibility: On the project quick-turn PCB, you can improvise a factory with small or no significant delays or cost implications.

- Cost-Effective: Though rapid turnaround services may start with slightly higher expenses at the initial stages compared with normal manufacturing, the ability to detect design errors during earlier stages can even guarantee to cut down on the on the overall cost of later-stage rework in the production process.

- Competitive Edge: In the current challenging environment, the capacity to speedily test and improve is a great asset, enabling companies to overcome difficulties and fulfill their potential in the market.

What are the production process of printed circuit board quick turns?

The manufacture speedy delivery of a printed circuit board (PCB), or quick turn pcb fabrication, goes through such necessary stages as PCB design, PCB specifications, fabrication, and verification. The essence of each stage is the speed and efficiency it contributes to ensuring that all these swift deadlines are met. While specific processes may vary slightly depending on the manufacturer and project requirements, the general steps involved in quick-turn PCB production are as follows:

- Design Review: The first step is to make a detailed evaluation of the PCB design files supplied by the customer. Design engineers review the design for any bugs, oversights, or difficulties with the manufacturing method that could cause production troubles. Then the details are verified, and corrections are made if necessary for the design to meet the specifications of manufacturing.

- Material Procurement: After agreement on design and acquiring the materials needed,. Such an operation would entail buying the bare PCB substrate, copper foil, solder mask, etc., which are all components required for assembly. Vendors with this kind of service adopt long-term partnerships with suppliers to shorten lead times for supply materials.

- Board Fabrication: The production of empty printed circuit boards will be the next step. This involves several sub-steps:

- Film Generation: Based on the input files of the PCB design format, the software will make a pattern of the PCB and a film of the photo to be used in the exposure process.

- Lamination: Using multi-layer stacking, substrate materials and copper foils are laminated into one central part of the PCB.

- Circuit Patterning: The image facility is employed to disclose the circuit pattern onto the printed circuit board substrate through exposure and development to the offshore manufacturing facilities.

- Etching: When a desired amount of copper is exposed to chemicals, it etches away, leaving just the desired PCB tracks behind.

- Drilling: Through holes, the PCB design provides holes for mounting the components and connecting the components.

- Component Procurement: With PCBs being built, the commodities are being bought for assembly. With quick-turn services, the company will keep a stationery of frequently used components to compensate for the increased speed.

- Assembly: Now that the bare PCBs and components are ready, the assembly procedure kicks off to assemble those parts. This typically involves the following steps:This typically involves the following steps:

- Solder Paste Application: Solder paste is dispensed on the PCB using a stencil, and consequently, spots where the paste is applied indicate the area where the components will be placed.

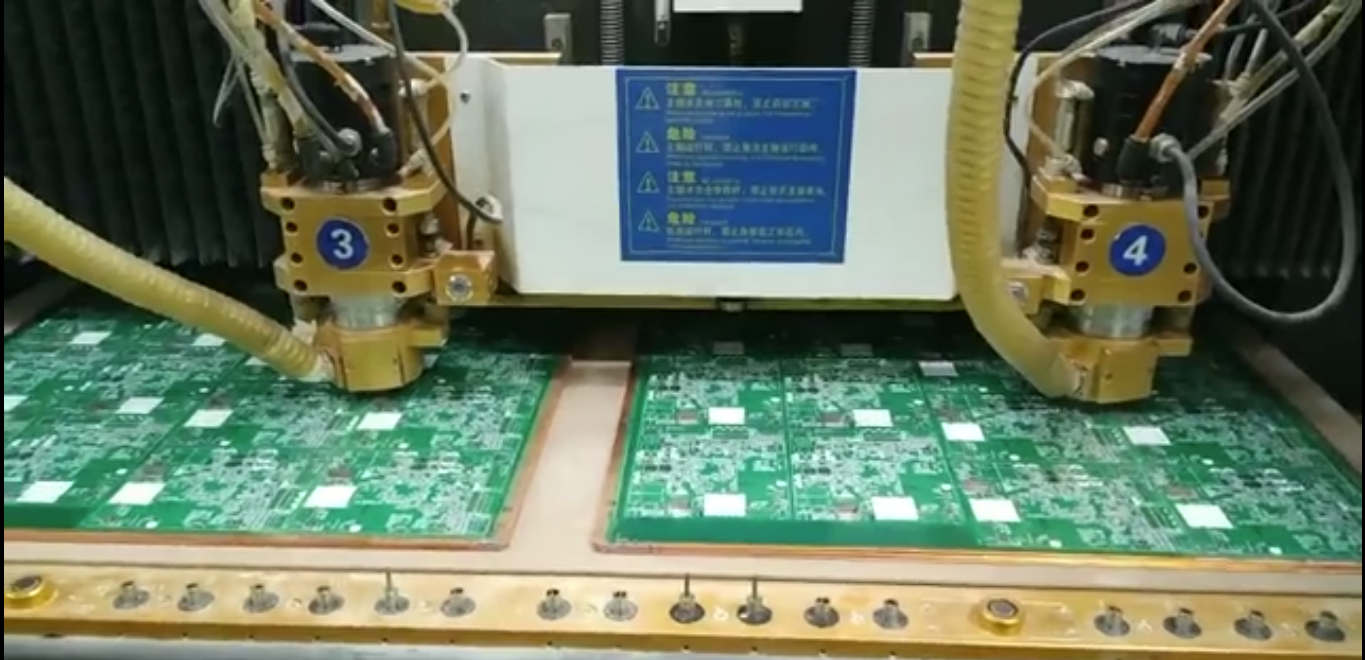

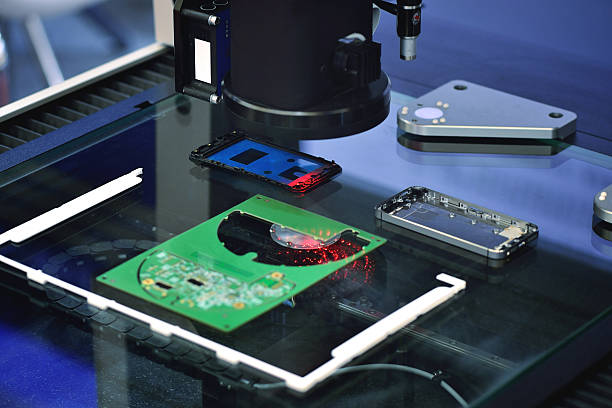

- Component Placement: On their PCBs, automated pick-and-place machines or manual assembly techniques are used to mount the elements in accordance with the design specifications.

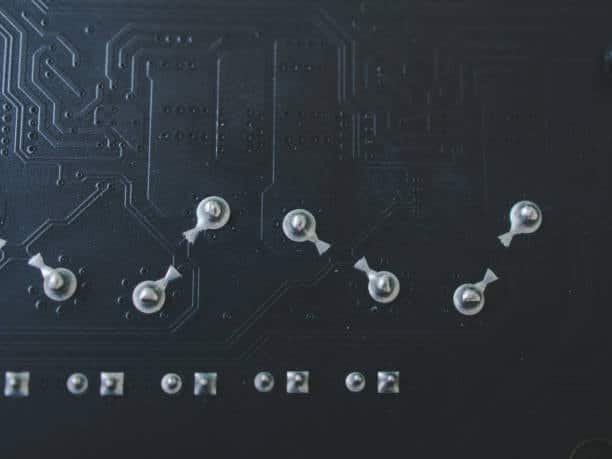

- Reflow Soldering: The modular boards undergo reflow oven treatment, in which the solder paste is melted, allowing components to be soldered to the PCB’s surface.

- Inspection and Testing: Finally, the assembled boards are examined visually during the soldering process and subjected to functional examinations to guarantee good and dependable quality.

- Finishing:Ultimately, a batch of clean and quality-controlled PCBs is inspected and packed for shipping to an end-customer. Rapid response services focus on quality perishable handling, inventory tracking, and infrastructure that shortens the time it takes to send out an order before the requirement period is over.

Tips for Mastering PCB Quick Turn

PCB rapid turn means you should go that extra mile to streamline all the production stages as well as pinpoint the weak components in order to increase efficiency and reduce duration with full production phases. Here are some tips to help you master PCB quick turns:

- Optimize Your Design: Before your design goes to quick-turn manufacturing, make sure it is paramount for manufacturing. The incorporation of the aforementioned elements may involve following design rules and avoiding materials with complex features as well.

- Choose the right partner: Not an equal playground, for sure, all quick-turn PCB manufacturer exist. Finding a proven forerunner who offers timely production of high-class boards is a great idea.

- Communicate Clearly: Undoubtedly elucidate your demands, which include the desired lead times, specifications, and any special necessities. That is intended to avoid misconceptions andthe flawless implementation of projects.

- Plan for Iterations: Quick turn services obviously allow for rapidly prototyping, but you must still plan for iterations since they are a part of the whole process of designing an effective product. Account for the testing, debugging, and re-iteration of the design, which will be based on the feedback that you and your team received.

- Stay Agile: Adopt an open-ended, rapid-prototyping approach. When testing and getting feedback are done, we are ready to adjust and reshape the product to make it better.

Conclusion

The critical necessity of being able to perform PCB quick turns cannot be overlooked by anyone who endeavors to remain competitive in the contemporary electronic market, which is mainly characterized by high speeds aerospace quality. Through knowing the good sides of quick-turn PCB project and applying prompt prototyping methods and production, you will be able to make the development faster, decrease the market time, and then finally, the marketable products will come to market first and complete production runs. Ah yeah, from slow and arduous to fast with the latest technology and the most fine-tuned designs. Be the one who turned ideas into reality in the blink of an eye of its production services.