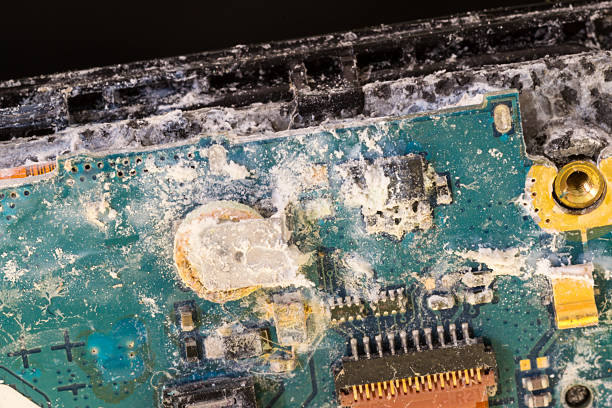

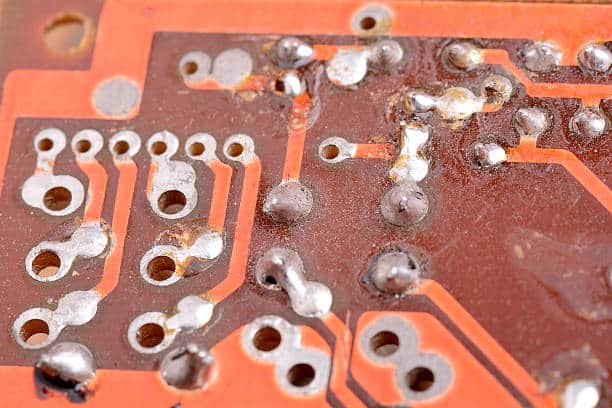

Tracks on the printed circuit boards are a mess for electronics lovers and those that pro. Whether corrosion arises from moisture, humidity or chemical agents, it may lead to malfunction, disconnection problems and, ultimately, complete device failure. Nevertheless, with proper methods and instruments, covering up the corrosion would be an easy and self-confidence building task. In the forthcoming tutorial, we will take a look at the smart tactics for a thorough clean and corrosion removal from the circuit board; thereby, maintaining the essential functionality of this device and minimizing the risk of failure for a long period.

Understanding Corrosion

Situation with corrosion of a board of passage is widespread and can hugely influence the functioning and reliability of electronic gadgets such as electrical voltage or other electrical connections. Water is a main cause of corrosion on circuit boards, as it, often penetrating the to protective layers and leads to oxidation of the metals. Increased level of oxidation will give rise to the formation of metal oxides which will adversely affect electrical connection and put the circuitry to non-functional state. Electrochemical reactions can also take place when different metals are in contact of one circuit board and they lead to faster corrosion of the less noble one.

Impurities like dirt, dust, and chemicals not only effectuate the corrosion speed through the additional channels for water and oxygen ingress but also impact oxidation. Recognizing the causes of corrosion on circuit boards is a key factor in an effective prevention and reduction strategy, that could among other things include protecting circuit boards with coatings, sealing the enclosure to prevent ingress of dust, humidity and chemical corrosives, and doing regular maintenance to control the environmental conditions around the circuit board.

WHAT IS PCB CORROSION?

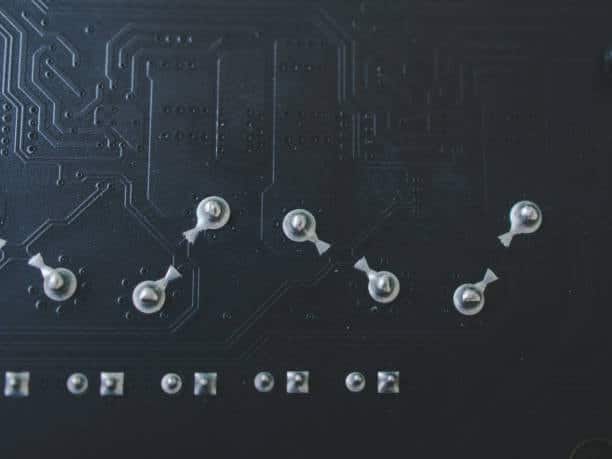

Extensive blotchwork of metal components lying on board called PCB prevent moisture buildup is evidence of damage that comes as a result of the influence of external factors such as humidity, moisture and chemical contamination either in the circuit board contamination. That corrosion resulting in malfunction and collapse of electronic devices is a huge issue to be remembered. When water molecules or humidity arrive at the PCB’s metal parts, they produce copper oxide or salts on the surface, which in turn form the patina. The effect of chemicals on the corrosion of materials can be amplified through the corrosive action Your primary goal when trying to prevent PCB corrosion should be to avoid ionic contamination.

Fretting Corrosion this type of corrosion results from the constant closing of the solder plate, which leads to erosion of the surface oxide layer. PCB corrosion could lead to the breaks off of circuit paths, irregularities in current flow, and the failure of the board itself device failure. prevent PCB corrosion is done by application of corrosion-resistant coatings, sealing the box not allowing ones blow part, and selecting the materials not sensitive to corrosion. Regular maintenance and controls are also other ways that can identify at initial stage and correct corrosion problems.

WHAT ARE THE FORM AND TYPES OF CORROSION?

Corrosion can differentiate itself by its many forms, colors, and strength. As we look at its creations we see the weakness of metal materials this time in a different way. The most common forms of corrosion include:The most common forms of corrosion include:

Uniform Corrosion from circuit boards

This particular type of corrosion happens on the surface of a particular material in an entirely uniform way which leads to a corresponding decrease in the overall thickness of the material. High corrosion risk is quite frequently observed due to water or chemicals.

Galvanic Corrosion occurs

Galvanic corrosion happens when two metal types are bumped against each other having electrolyte (saltwater) on board. The formerly metal one will oxidize and the latter metal would be protected.

Pitting Corrosion from circuit boards

Pitting corrosion is associated with the formation of small pits or craters on the surface of materials. The damage develops locally, leading to corrosion pits, which ultimately destroys metal if this process is not inhibited. It may result from chlorite ions and other aggressive agents.

Crevice Corrosion from circuit boards

Crevice corrosion finds the small areas known as crevices where oxygen concentration is poor. Wear is mostly by its presence in area of water being retained, for example, under gaskets or under bolt heads.

Filiform Corrosion

ASTM referred to the corrosion process as filiform corrosion, where it could exhibit a worm like or thread like pattern on the surface of the material in the presence of moisture or oxygen.

Intergranular Corrosion

Grain-boundary corrosion is a wet kind of corrosion in microscopic structures of a substance that usually occurs due to sensitization or other material processing causes.

issues.

Stress Corrosion Cracking (SCC)

SCC stands for Stress Corrosion Cracking and it happens in a situation when stress is induced in the presence of corrosive environment. This finite element analysis study is for those, who want to know more about stress intensity factors and their impact on the material.

HOW TO CLEAN CIRCUIT BOARD CORROSION?

Surface-mounted integrated circuits must be cleaned with utmost care because any incorrect moves can easily burn the board. Here’s a general guide on how to clean circuit board corrosion effectively:

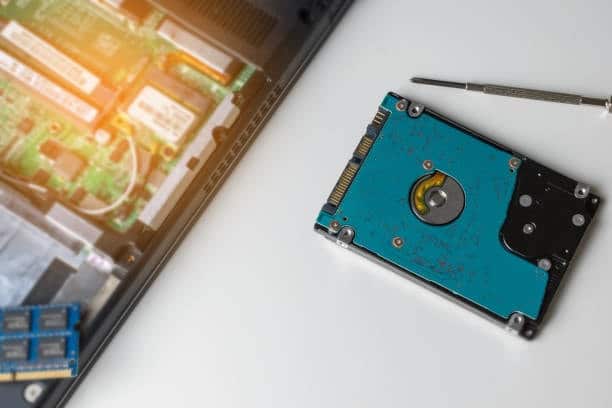

- Safety First – Before proceeding provided that the board is disconnected from any power source and the board is placed at a static-free surface to avoid electrostatic discharge (ESD) damage.

- Assess the Damage – Check the loudspeaker board for the presence of any severe corrosion and determine the affected areas that need to be cleaned.

- Gather Supplies – The only things you will require are isopropyl alcohol, soft-bristled brushes, lint-free cloths, distilled water (if best cleaning result is required into the circuit board cleaning), and an ultrasonic cleaner (optional).

- Brush Away Debris – Get soft-bristled brush to spend real time to get off all the loose stuff all those debris and stay off.

- Apply Isopropyl Alcohol –While wearing gloves, apply isopropyl-alcohol-moistened lint-free cloth on the not-incorrect sections and wipe the affected area to dissolve the corrosion. Avoid board battering moisture, because over moisture can cause breaking.

- Scrub Gently – For those more stubborn types of oxidation, use a soft-bristled brush dipped in alcohol to delicately wipe off the spots that are corroded circuit board.

- Rinse (Optional) –If needed, you could rub the wooden surface with a cotton cloth soaked in distilled water if it doesn’t disappear.

- Dry Thoroughly – Take time for the circuit board to dry thoroughly. Only after that you should try to connect it to the power or any electronic device.

WHAT MATERIALS OR TOOLS CAN BE USED FOR CLEANING CIRCUIT BOARD CORROSION?

Several materials and tools can be used for cleaning pcb corrosion, including: Several materials and tools can be used for cleaning circuit board corrosion which are all of these are specialized pcb cleaning tool, including:

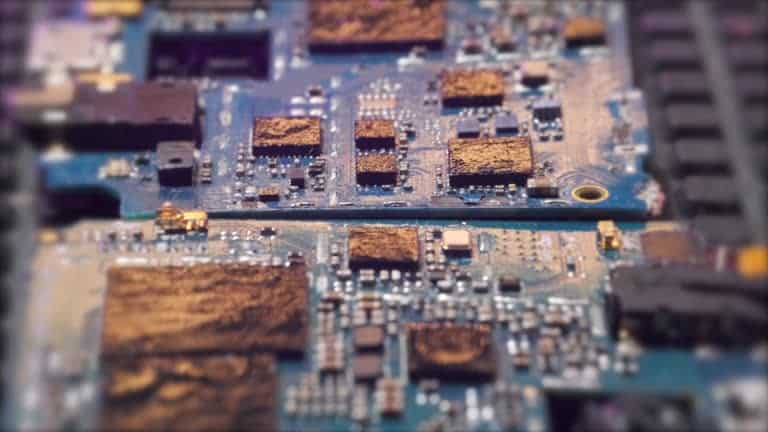

- Isopropyl Alcohol: Furthermore, the use of a solvent such as IPA (Isopropyl Alcohol) is frequent for cleaning circuit boards because it is evaporate rapidly and leaves no residue after that.

- Soft-bristled Brush: Use of a liquid solution, which is commonly a degreaser or an oxidant, to gently clean the board’s surface from corrosion and debris without damaging delicate components.

- Lint-free Cloths: Its purpose is to dissolve corrosion or residue left on the board and to rinse it all clean away by using solvents.

- Distilled Water: A spray applicator supplies the cloth with the last rinse with the solvent. Thereby it makes it free from any remaining residue.

- Ultrasonic Cleaner: Propaganda doesn’t touch the heavily corroded boards, but it has a minor function of sound waves, which are used to dislodge the debris.

- Corrosion Inhibitors: Chemicals with properties to prevent corrosion additively after cleaning process is done.

- Conformal Coating: A protective coating that can be applied after cleaning will stop the metal parts such as resistant metal, metal surfaces, metal degradation, metal ions bond, noble metals, exposed metal, metal slivers or more resistant metal or either creating metal slivers forming these legs getting corroded again in the future.

- Safety Equipment: Handling solvents and chemicals should be done after ensuring that such chemicals are put in gloves, goggles and enough ventilation.

In short to prevent corrosion and clean a circuit board is you need to prepare the baking soda and water on it to measure by pouring a water you need a two or four parts of the water until it will result to thick paste. After becoming a thick paste you will your brush or soft bristles just to scrub it to the solution over all the area corroded. After all the process are done you need to wait 20 to 30 minutes to dry the circuit boards after drying rinse more distilled water.

CAN YOU CLEAN CORROSION FROM CIRCUIT BOARDS?

Yes, corrosion can be cleaned from circuit boards like clean pcb corrosion. Though the trouble it brings can be undermining, one has to be careful not to cause any harm to the components. This involves opening of power source, board placement on a static surface with insulation, a ground strap to conduct discharge to yourself, and a non-metallic anti-static wrist strap. Take extra precaution to gather the place and strength of the corrosion.

A soft brush with the bristles cleaning solution the residue and rust should be utilized to remove debris from the top of the board. Subsequent, dip a lint-free towel in an alcohol and isopropyl solution to dissolve and clean the corrupted portion by wiping gently. Hi-moisture level may be harmful, and therefore, always ensure alcohol abundance is not too much. For stains that are difficult to remove, you might consider using an alcohol-soaked delicate brush to scrub softly. If this is the case, fill in the board with distilled water for a second time in order to eradicate the residue and let it dry while out of power.

WHEN DOES THE GALVANIC CORROSION OCCURS?

The phenomenon of galvanic corrosion happens when a different method to the present one is used in conditions with the presence of an electrolyte (like salt water). When exposed to a high oxygen content environment, the more reactive metal will corrode and the less reactive one may be protected. This particular form of corrosion may develop for example whenever dissimilar metal materials are in contact, e.g. the plumbing systems, electric connections and marine environment.

TIPS HOW TO CLEAN a circuit board?

In order to avoid breaking off any of the components, it is essential to work carefully while cleaning a circuit board. Adhering to the tips provided above can assist in making a circuit board spotless, minimizing the risk of damage during the process. Here are some tips:

- Safety First: First, always disconnect the board from the power supply, then use conductive precautions to avoid any possible elemental damage.

- Assessment: Found damaged area and cleaning are needed.

- Gentle Cleaning: Lightly sweep away dirt and corrosion with brush, taking care to avoid hard-bristled brushes. Internet

- Solvent Application: Try to make sure that the sanitizer that is in the isopropyl alcohol wipe is off with a lint-free soft cloth. Avoid excessive moisture.

- Stubborn Areas: You use a soft brush which you had previously dipped in alcohol for those stubborn marks.

- Rinse (Optional):Wipe the board thoroughly and if neccessary, rinse it with distilled water to remove the residue.

- Drying: Give a board half an hour or more to compressed air dry completely before you link it to the electricity source.

- Prevention:For the future treatment, you could use conformal coatings or enclosures to keep the parts from corroding.

FAQS

What causes corrosion on circuit boards?

However, standing water or humidity on circuit boards can quickly cause corrosion. Such factors can help make oxides or salts, which contribute to the destruction of its abilities, forming on the metal elements of the entrance.

How can I identify corrosion on my circuit board?

Signs of corrosion are manifested as discolored color of metal elements or greenish some areas, visible residue, and/or a peculiar smell (like burnt or rotten) which spread from card. In addition, you may get frequent error signs displayed or devices may exhibit abnormal operations.

Can I clean corrosion from my circuit board?

Yes, you can clean corrosion from your circuit board. It demands to monitor the parts to be safeguarded from harmfulness. Equally, add some isopropyl alcohol along with soft bristles of a brush to clean the corroded parts, after which let the board to air dry completely before you reconnect it to the existing corrosion.

How often should I clean my circuit board to prevent corrosion?

Tools as an environmental component creates the basis for cleaning frequency as it depends on environmental conditions, the number of circuits, and extent of their usage. A maintenance schedule that ensures regular inspection and cleaning corrosion will minimize the chances of rusting and go in line with the optimal performance just to preventing corrosion.

Are there any preventive measures I can take to protect my circuit board from corrosion?

Yes, you can take several preventive measures, for example, by coating the circuits with shielding coats, closing up the enclosure, and storing the equipment in a conditioned place with constant of humidity and temperature.

Conclusion

Ultimately, overcoming corrosion in your printed circuit board is a well-manageable task ad your will achieve using the right techniques and tools such as to determine the atmospheric corrosion just to classified it those atmospheric kinds of corrosion in such the oxygen it is very critical component of moisture but copper experiences atmospheric corrosion it said the it is very easily which is not the problem of the copper plumbing it is because of the corroded copper retains to the electrical conductivity into the circuit board components. Being aware of the factors that trigger corrosion as well as adopting a good one including careful cleaning and preventive measures will help you avoid untimely breakdowns of your devices to extend their functionality and lifespan either in the localized corrosion. To prevent and clean a circuit boards you need to prepare the baking soda and water on it to measure by pouring a water you need a two or four parts of the water until it will result to thick paste. After becoming a thick paste you will your brush or soft bristles just to scrub it to the solution over all the area corroded. After all the process are done you need to wait 20 to 30 minutes to dry the circuit boards after drying rinse more distilled water. Electrolytic corrosion occurs when neighboring copper traces become contaminated by an ionic liquid or electrolytic solution or in the ionic contaminated moisture infects of the electroless nickel immersion gold. Ensure high levels of safety at all times by unplugging the board from the power source and employing appropriate protection from static. The periodical service and control can let corrosion be reserved before the circuit board inside are spoiled completely; the circuit board dry will always be clean and work well.